Tunnel excavation construction method of completely weathered granite shallow-buried water-rich layer milling excavator

A technology of tunnel excavation and construction methods, which is applied to chemical instruments and methods, tunnels, tunnel linings, etc., and can solve problems such as large disturbance of the tunnel face, poor self-stabilization ability, and high water content of the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

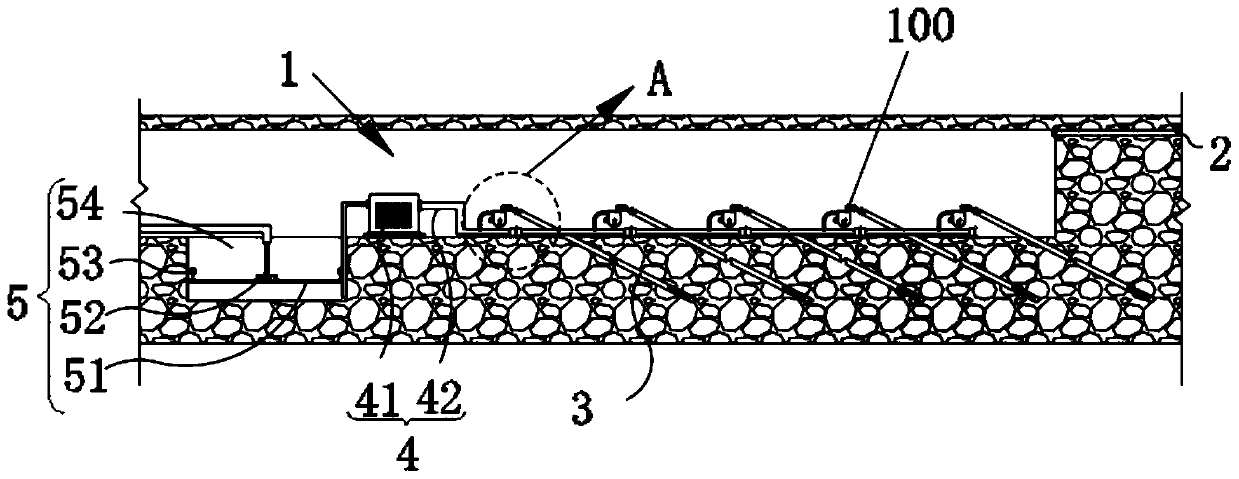

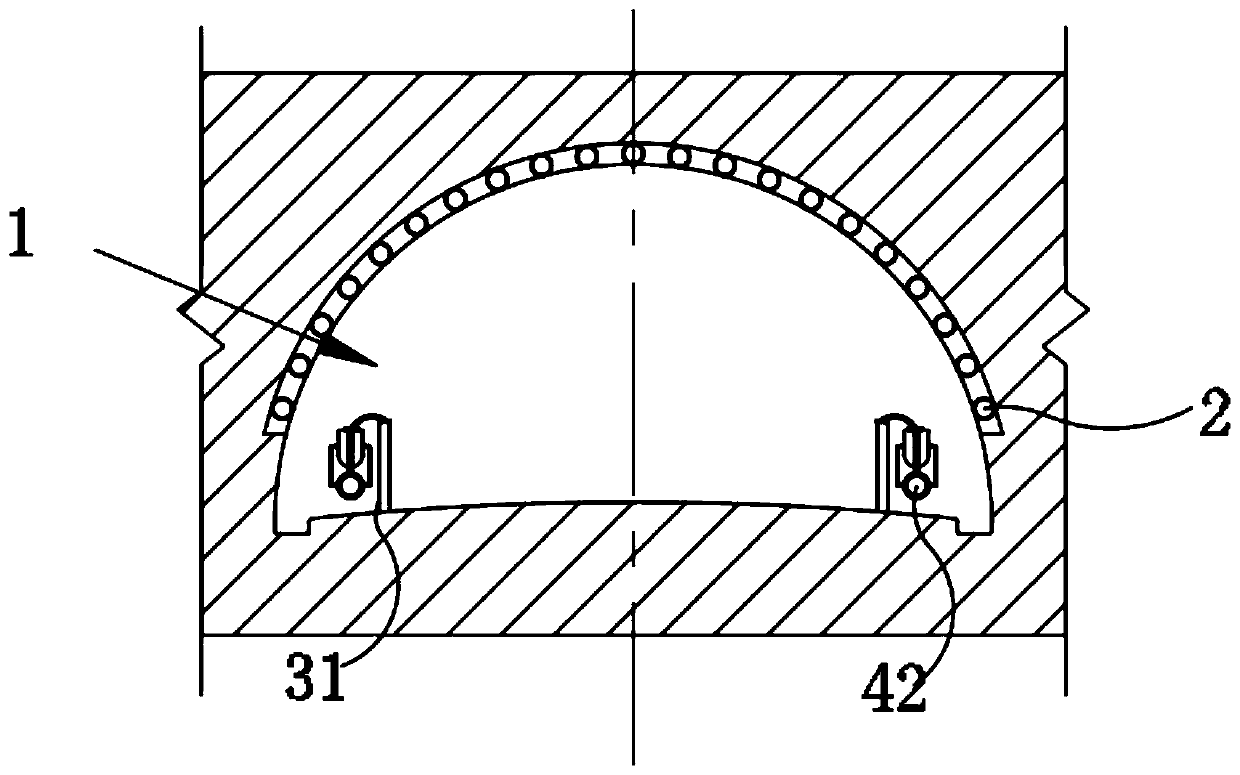

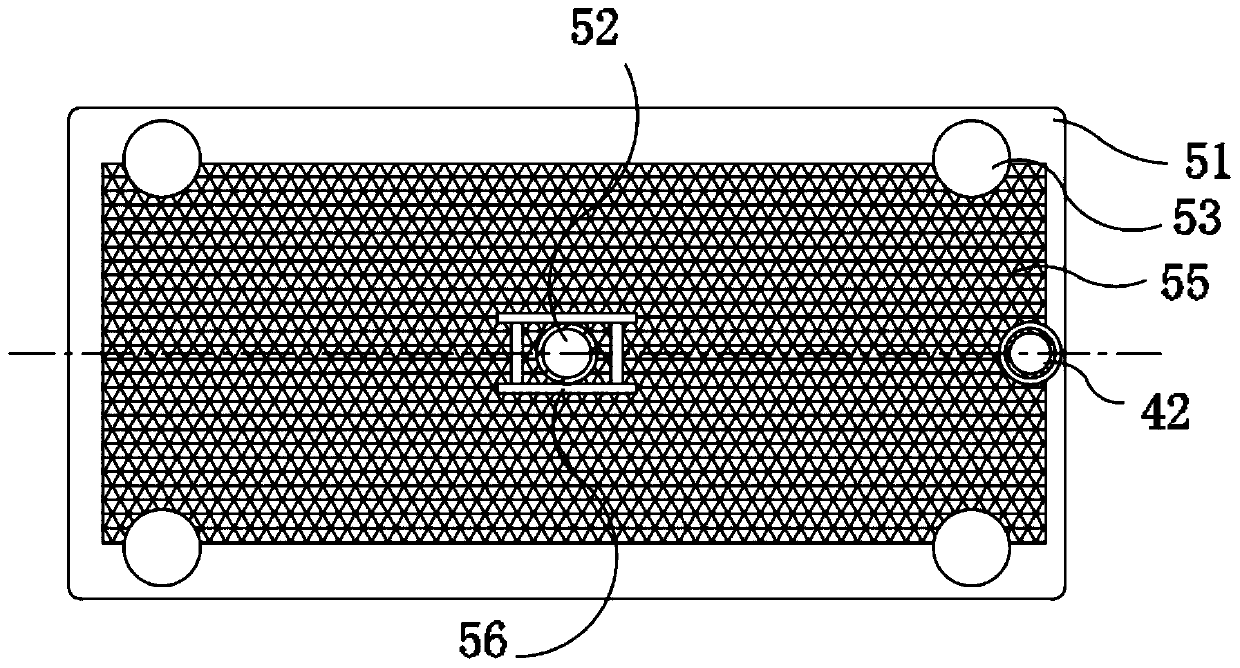

[0027] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 in, figure 1 Schematic diagram of the construction method for excavating the excavation tunnel of the fully weathered granite shallow buried water-rich layer milling machine provided by the present invention; figure 2 for figure 1 The tunnel section shown; image 3 for figure 1 The top view of the sponge pad structure shown; Figure 4 for figure 1 The enlarged schematic diagram of the structure at A shown; Figure 5 for Figure 4 The schematic diagram of the internal structure of the cylinder is shown; Figure 6 for figure 1 The schematic diagram of the structure of the drainage mechanism is shown. The tunnel excavation method of fully weathered granite shallow buried water-rich layer milling excavator includes:

[0028] S1: Use conduit 3 for pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com