A set of reinforced anti-torsion interlocking intramedullary nails

An intramedullary nailing and interlocking technology is applied in the field of reinforced torsion-resistant interlocking intramedullary nail kits, which can solve the problem that the location and type of femoral shaft fractures are not subdivided, the screws at both ends of the fracture site are far apart, and the local mechanical environment is inconsistent. It is beneficial to active osteogenesis, enhance anti-rotation ability, and improve the local mechanical environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

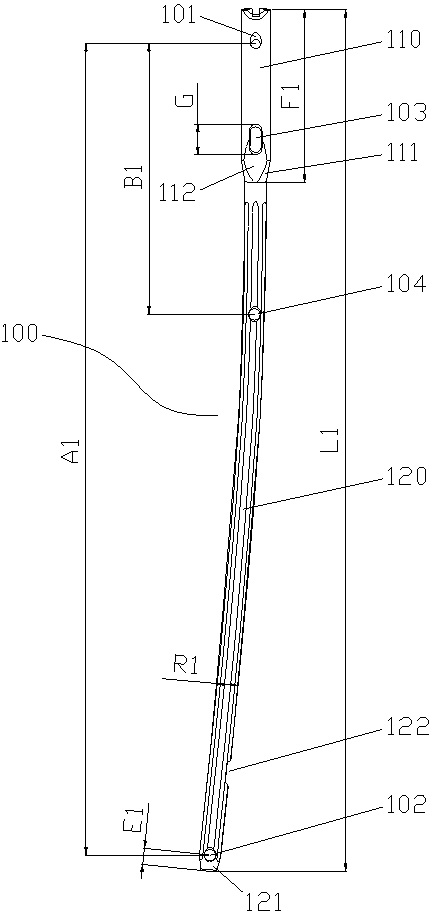

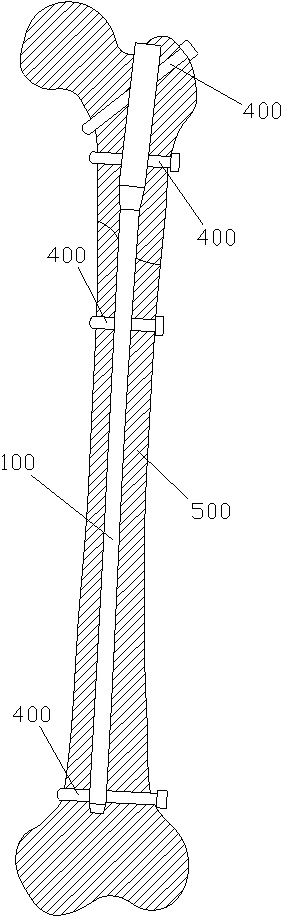

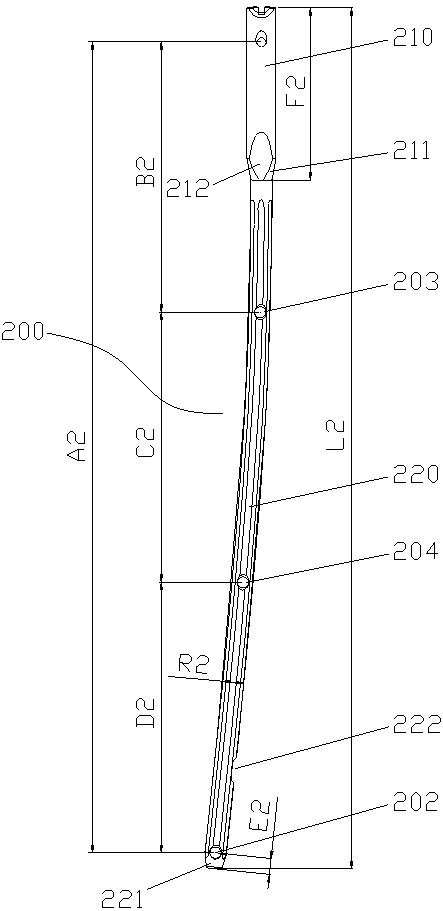

[0026] Embodiment one: if Figure 1~6 As shown, the present embodiment provides a reinforced anti-torsion interlocking intramedullary nail set, including:

[0027] The first intramedullary nail 100 is used to fix the upper 1 / 3 fracture of the femoral shaft 500; the first intramedullary nail 100 includes a first shaft section 110 and a first shaft section 120 distributed sequentially from near to far, so The proximal part of the first rod head section 110 is provided with a first most end static locking hole 101, and the distal part of the first shaft section 120 is provided with a first most distal static locking hole 102; There is also a first proximal power locking hole 103 on the first shaft section 110, the first proximal dynamic locking hole 103 is located at the distal end of the first shaft section 110, and the first shaft section 120 is also provided with There is a first distal static locking hole 104, and the center distance B1 between the first most proximal static...

Embodiment 2

[0039] Example 2: Please refer to Figure 1~6 , The difference between this embodiment and Embodiment 1 is that: the reinforced anti-torsion interlocking intramedullary nail set further includes at least four screws 400, and the screws 400 are matched with corresponding locking holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com