Functional raw material obtained by staged fermentation of flowers and fruits based on saccharomycetes and lactobacillus plantarum and application of functional raw material

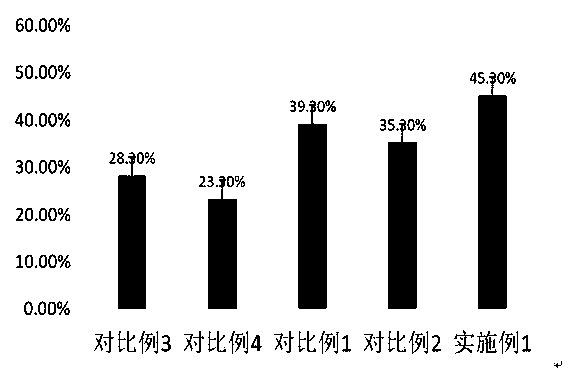

A Lactobacillus plantarum and staged fermentation technology, applied in the field of functional raw materials, can solve the problems such as the promotion and application of flavonoids in the unfavorable utilization of plant resources, low content of flavonoids, less application, etc. The effect of increasing the content of total flavonoids and increasing the activity of inhibiting tyrosinase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A functional raw material obtained by staged fermentation of flowers and fruits based on yeast and Lactobacillus plantarum, comprising the following steps:

[0044] S1. Pretreatment: Inoculate Saccharomyces cerevisiae in PDA medium for 24 hours at 28°C, collect yeast activation solution for later use; inoculate Lactobacillus plantarum in MRS medium, cultivate for 12 hours at 37°C, collect Lactobacillus plantarum activation solution for later use; Dry kudzu root, kudzu flower, malt, corn cob and orange, then grind the ingredients, pass through a 60-mesh sieve, and set aside;

[0045] S2. Add the yeast activation solution to the first fermentation substrate (10kg kudzu root, 10kg malt, 2kg glucose, 5kg molasses, and 100kg water), stir and ferment at 28°C for 24 hours, then raise the temperature to 40°C and stir and ferment for 72 hours. Bacteria-filtered air is introduced, and the added volume of the yeast activation solution is 5% of the first fermentation substrate;

[0...

Embodiment 2

[0053] A functional raw material obtained by staged fermentation of flowers and fruits based on yeast and Lactobacillus plantarum, comprising the following steps:

[0054] S1, pretreatment: with embodiment 1;

[0055] S2. Add the yeast activation solution to the first fermentation substrate (8kg kudzu root, 8kg malt, 1kg glucose, 2kg molasses, 100kg water), stir and ferment at 26°C for 20h, then raise the temperature to 38°C and stir for 65h, the whole fermentation process Bacteria-filtered air is introduced, and the added volume of the yeast activation solution is 3% of the first fermentation substrate;

[0056] S3. After the Saccharomyces cerevisiae fermentation is completed, the temperature is raised to 70° C., and the yeast fermentation liquid is collected after sterilizing for 20 minutes;

[0057] S4. Add the second fermentation substrate to the yeast fermentation liquid in step S3 to obtain a mixed bottom material. The second fermentation substrate includes the followin...

Embodiment 3

[0063] A functional raw material obtained by staged fermentation of flowers and fruits based on yeast and Lactobacillus plantarum, comprising the following steps:

[0064] S1, pretreatment: with embodiment 1;

[0065] S2. Add the yeast activation liquid to the first fermentation substrate (15kg kudzu root, 15kg malt, 4kg glucose, 8kg molasses, and 150kg water), stir and ferment at 30°C for 25h, then raise the temperature to 42°C and stir for 75h, the whole fermentation process Bacteria-filtered air is introduced, and the added volume of the saccharomyces activation solution is 8% of the first fermentation substrate;

[0066] S3. After the Saccharomyces cerevisiae fermentation is completed, the temperature is raised to 70° C., and the yeast fermentation liquid is collected after sterilizing for 20 minutes;

[0067] S4. Add the second fermentation substrate to the yeast fermentation liquid in step S3 to obtain a mixed bottom material. The second fermentation substrate includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com