Anti-tearing connector, assembling structure of flat cable and connector and mobile terminal

An assembly structure and mobile terminal technology, which is applied to the components of the connection device, connection, coupling device, etc., can solve problems such as poor contact, abnormal power supply, failure to pass the test, etc., and achieve the effect of improving reliability and avoiding joint damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

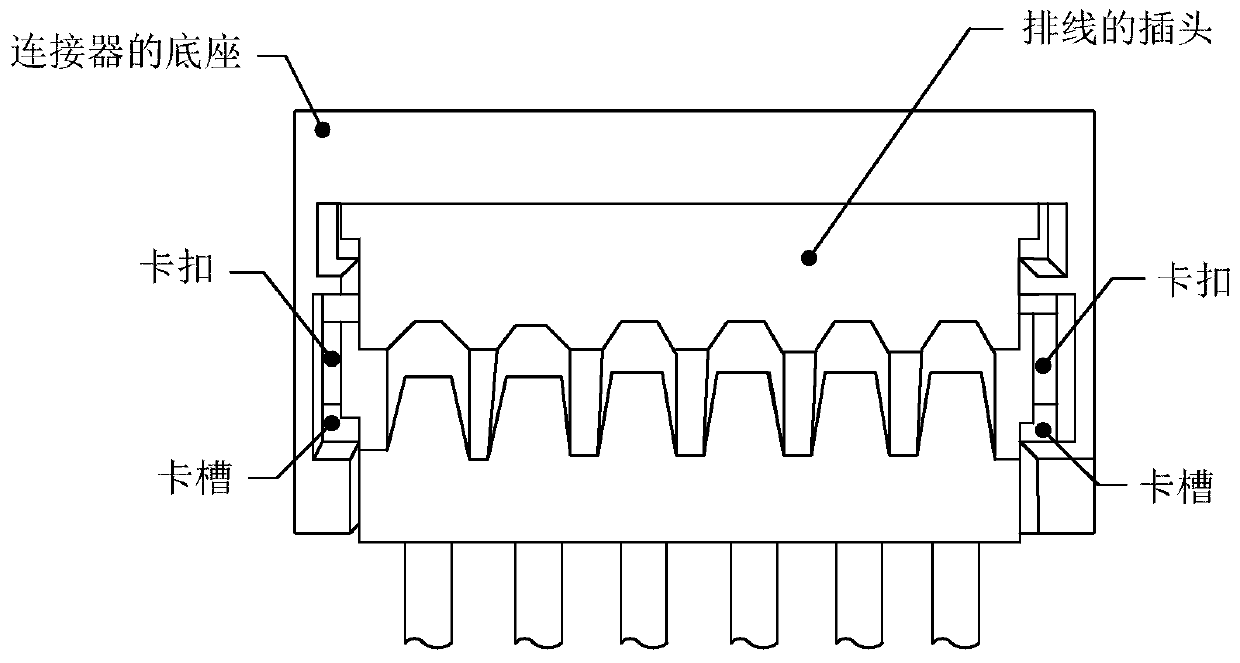

[0037] Please refer to image 3 with Figure 4 , the embodiment of the present invention provides a tear-resistant connector, including a base 10, and both sides of the base 10 are provided with a clip mechanism 20;

[0038] The clipping mechanism 20 includes a first clipping mechanism and a second clipping mechanism movable in the horizontal direction, and the first clipping mechanism and the second clipping mechanism are arranged oppositely;

[0039] When assembled with the plug of the flat cable, the plug can push the first buckle mechanism and the second buckle mechanism away from each other, so as to securely connect the connector with the flat cable.

[0040] It should be noted that, in order to ensure normal use, the connector provided by the present invention also has other conventional designs, such as metal shrapnel or contact pins provided on the base 10, but since these designs are not the focus of this design, here No in-depth elaboration.

[0041] In this embo...

Embodiment 2

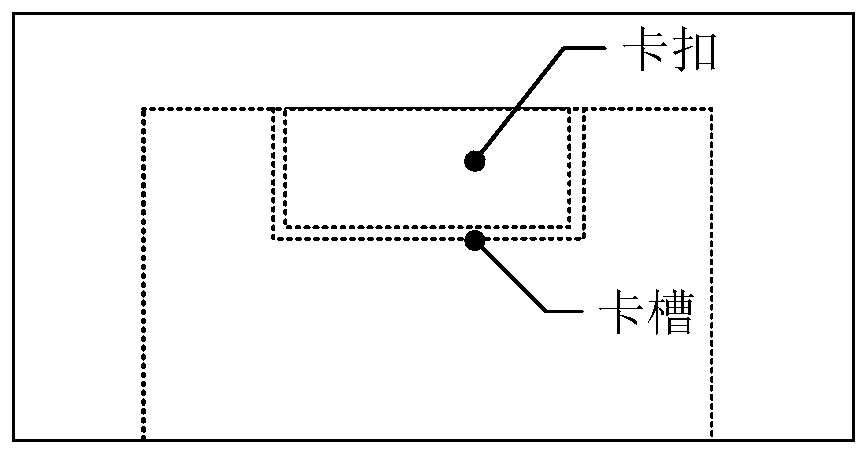

[0050] Please refer to Figure 5 with Image 6 , Embodiment 2 of the present invention provides an assembly structure of a tear-resistant cable and a connector, including a cable and the tear-resistant connector as described in Embodiment 1;

[0051]Both sides of the cable plug 100 are provided with buckling mechanisms 200 that cooperate with the buckling mechanism 20 of the connector.

[0052] In this embodiment, the buckle mechanism 200 is provided with a chamfer 300 for preventing the buckle mechanism 200 from coming off from the buckle mechanism 20 .

[0053] Preferably, the shape of the buckle mechanism 200 matches the shape of the buckle mechanism 20 .

[0054] The embodiment of the present invention provides an assembly structure of an anti-tear cable and a connector. By designing a first clamping mechanism and a second clamping mechanism that can move in the horizontal direction on both sides of the base of the connector, when the row When the plug of the cable is s...

Embodiment 3

[0056] An embodiment of the present invention provides a mobile terminal, and the mobile terminal includes the assembly structure of a tear-resistant cable and a connector as described in Embodiment 2.

[0057] It should be noted that the mobile terminal may be electronic equipment such as a mobile phone, a tablet computer, and a handheld game console. Compared with the existing mobile terminal, the assembly structure of the cable and the connector in the mobile terminal provided by the present invention has the function of buffering and absorbing energy, which can protect the connection between the cable and the connector when it falls.

[0058] In the mobile terminal provided by the embodiment of the present invention, a first clip mechanism and a second clip mechanism that can move in the horizontal direction are designed on both sides of the base of the connector. When between the clip mechanism and the second clip mechanism, even if the cable is torn by an external force,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com