A back-purging device for measuring gas pipelines

A gas pipeline and back-purging technology, applied in valve operation/release device, valve device, gas/liquid distribution and storage, etc., can solve the problem of weak purging force of constant-current micro-positive pressure purging device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] A back-purging device for measuring gas pipelines provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

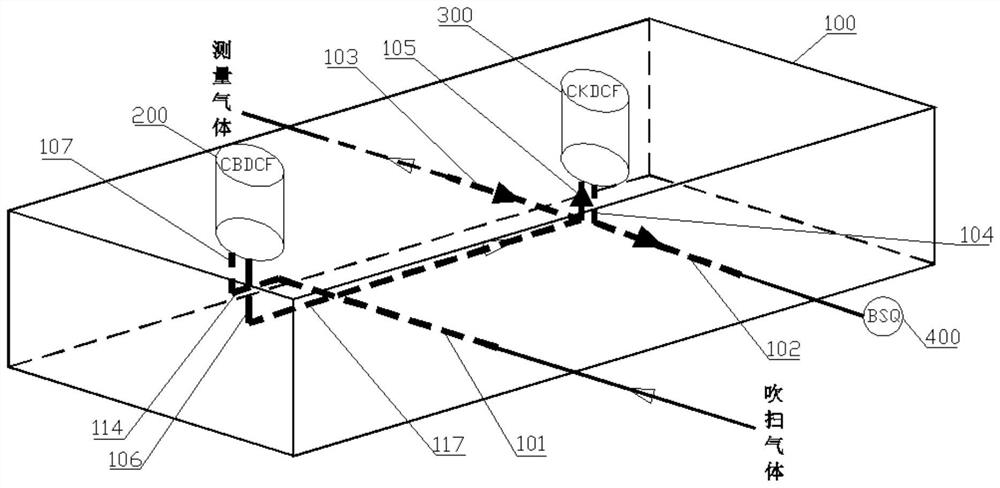

[0050] like figure 1 , is a schematic diagram of a back-purging device system for measuring gas pipelines provided by the present invention, including valve island 100, normally open solenoid valve 300, normally closed solenoid valve 200, measuring gas air volume / air pressure transmitter 400, Blockage monitoring pressure gauge (not shown) and device controller (not shown).

[0051] The structure of the valve island 100:

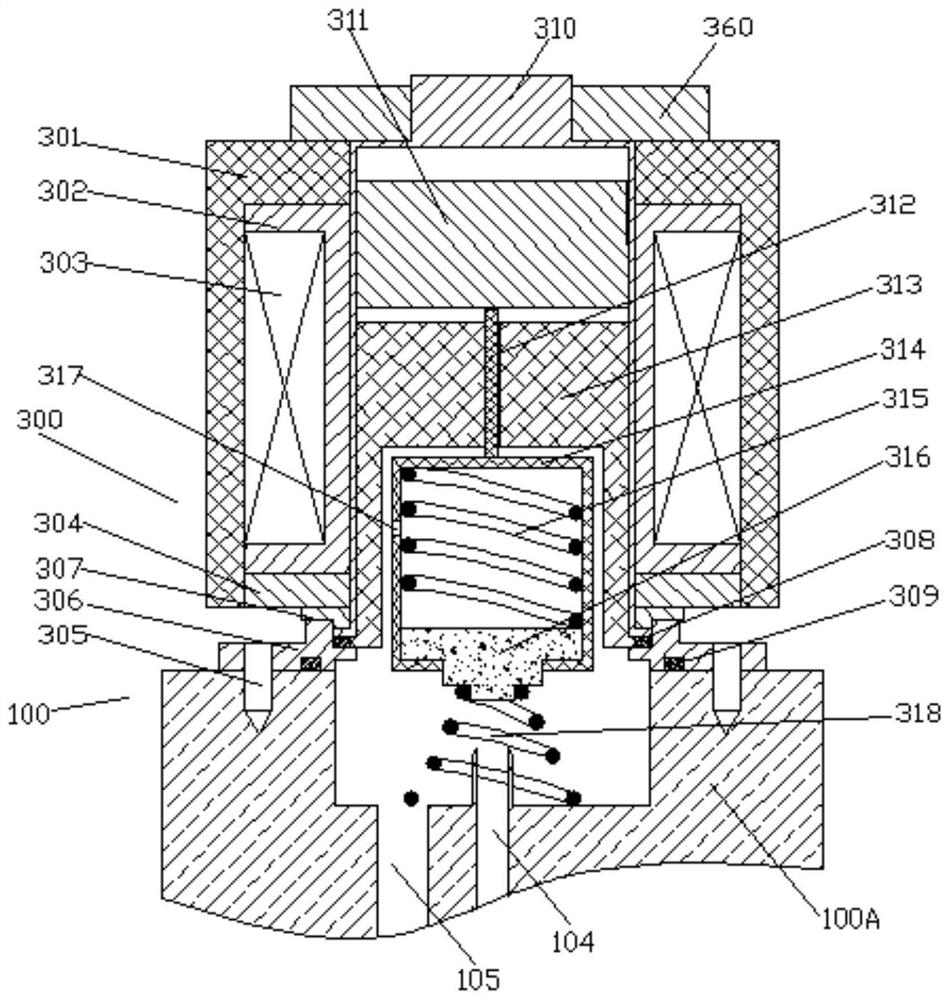

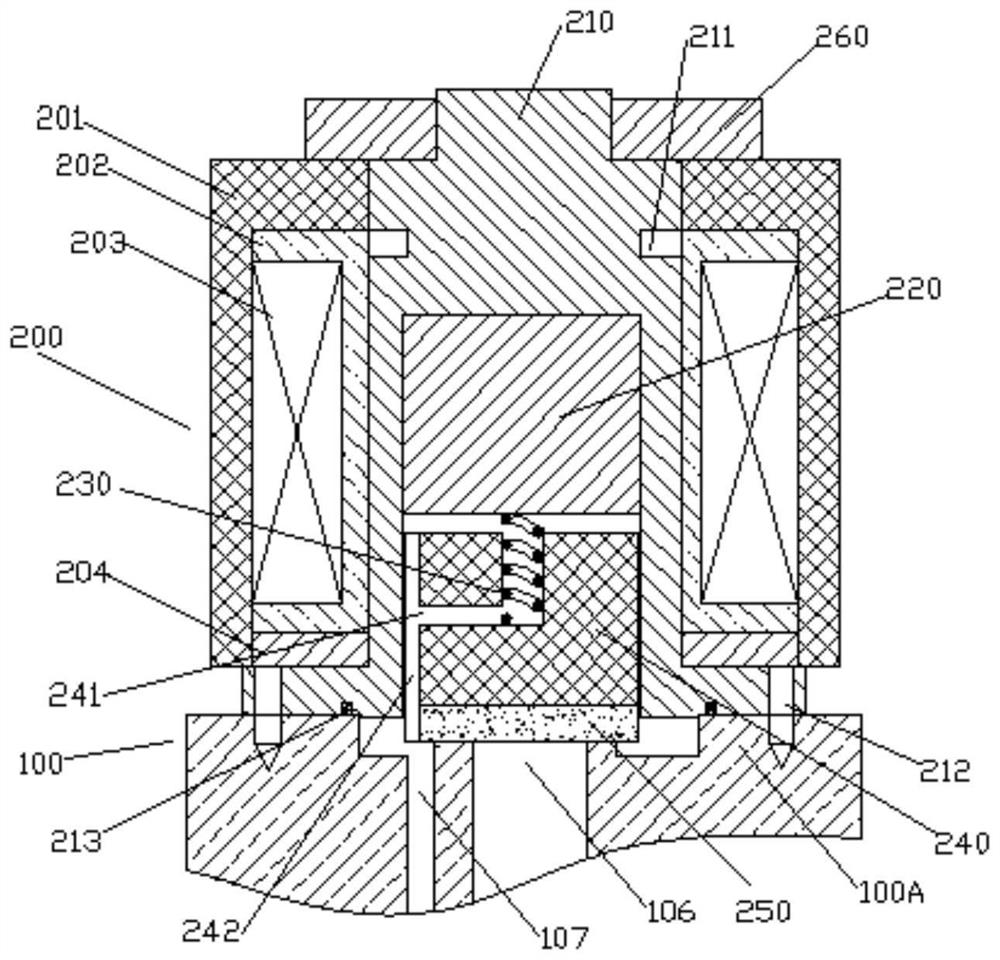

[0052] like figure 1 and Figure 4-10 , the valve island 100 includes a valve island body 100A and is provided with a purge gas pipeline, a measurement gas pipeline, a measurement gas circular groove 111 and a purge gas circular groove 108;

[0053] The measurement gas pipeline includes a measurement gas inlet pipeline (including 103 and 105), a measurement gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com