Fan with impeller fairing structure

A technology of shroud and impeller, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., to achieve the effect of improving the distribution of intake air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but it is not a limitation of the present invention.

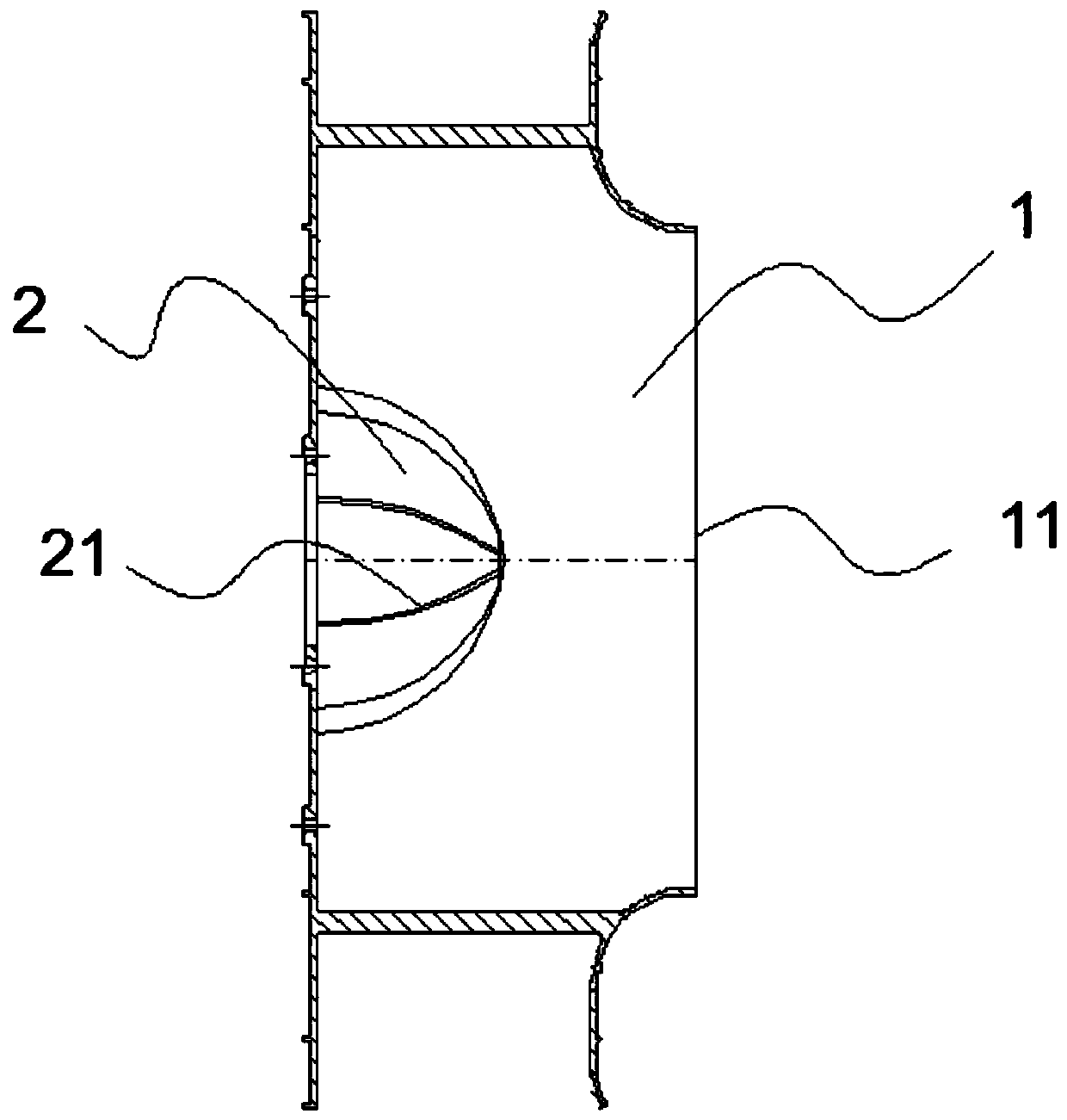

[0011] figure 1 Shows a fan with an impeller shroud structure, including an impeller body 1 and a finned shroud 2. The finned shroud 2 is hemispherically fixed on the inner surface of the impeller body 1 away from the air inlet 11 And with the air inlet 11 as the center, the outer surface of the fin-type deflector 2 is evenly provided with fins 21 that open outwards. The external airflow enters from the air inlet 11 and then divides by the fins 21 on the fin-type deflector 2. After that, the purpose of uniformly guiding the airflow to each part of the impeller body 1 is achieved.

[0012] The fins 21 are vertical fins, which are distributed evenly from the top center of the fin-type deflector 2 as the starting point to the bottom.

[0013] The fins 21 are spiral fins, which are distributed spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com