A kind of automobile sealing strip and its preparation system and preparation method

A technology of automobile sealing strip and preparation system, which is applied in the field of automobile sealing strip and its preparation system and preparation, can solve the problem that the sealing strip is not hollow, and achieve the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

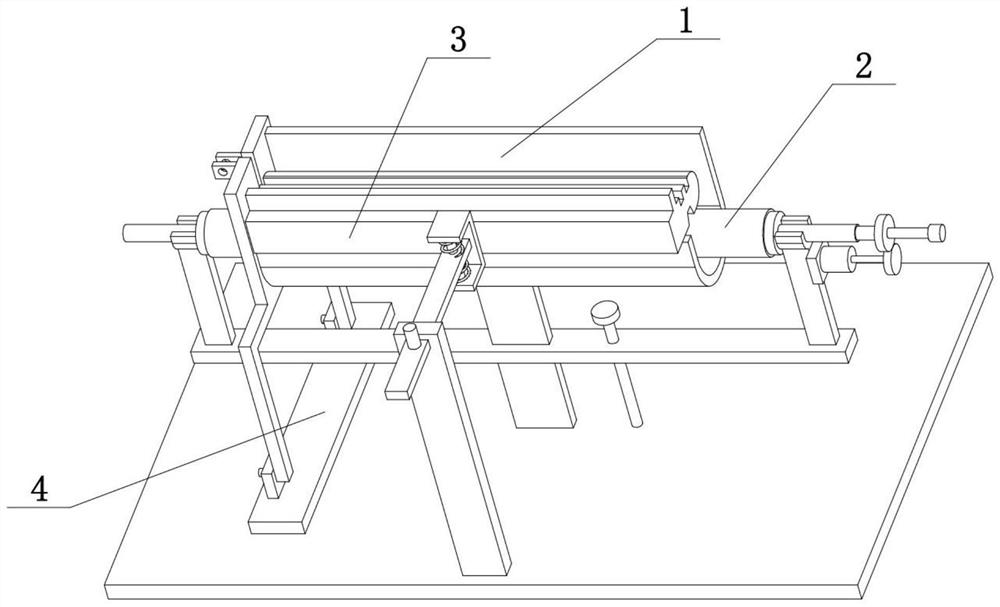

[0029] Combine below Figure 1-7 To illustrate this embodiment, the present invention relates to the field of sealing strip preparation, more specifically a system for preparing automobile weather strips, including a U-shaped plate 1, a heat-resistant rubber cylinder 2, a disc 201, a round tube 202 and a vent hole 203, The invention can prepare a hollow sealing strip with cushioning effect.

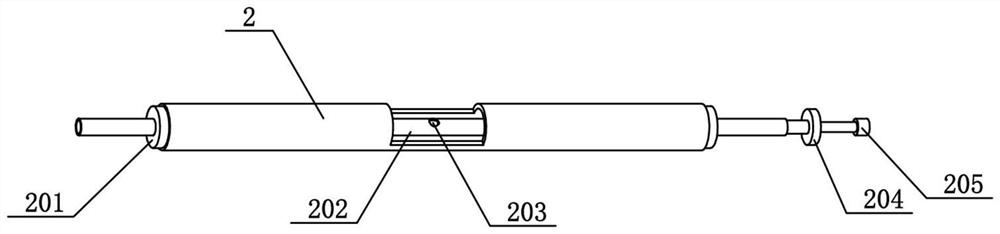

[0030] The heat-resistant rubber cylinder 2 is horizontally arranged inside the U-shaped plate 1, and the left and right sides of the heat-resistant rubber cylinder 2 are fixedly connected with discs 201, and the left and right ends of the circular tube 202 are respectively fixedly connected with the two discs 201. , The circular tube 202 is arranged coaxially with the heat-resistant rubber cylinder 2, the middle part of the circular tube 202 is provided with a ventilation hole 203, and the left end of the circular tube 202 is open and the right end is closed. When in use, insert the hea...

specific Embodiment approach 2

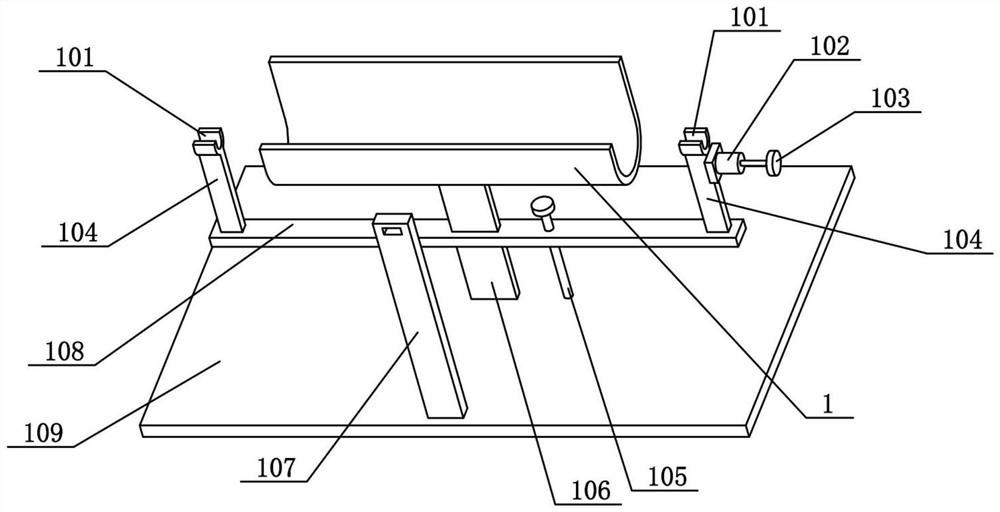

[0031] Combine below Figure 1-7 To illustrate this embodiment, the automobile sealing strip preparation system further includes a semicircular groove 101, a support rod 104, a thumb screw 105, a support rod 106, a lifting strip 108 and a bottom plate 109, and the lower side of the U-shaped plate 1 is fixedly connected with a support rod 106, a lifting bar 108 is horizontally arranged on the support bar 106, and the left and right ends of the lifting bar 108 are fixedly connected with a support rod 104, and the upper parts of the two support rods 104 are fixedly connected with a semicircular groove 101, and the left and right ends of the circular pipe 202 Inserted on the two semicircular grooves 101 respectively, the lifting bar 108 is threadedly connected with a thumb screw 105 , and the lower end of the thumb screw 105 pushes against the bottom plate 109 . When turning the thumb screw 105, the lifting bar 108 can be controlled to lift, and then the two support rods 104 can b...

specific Embodiment approach 3

[0032] Combine below Figure 1-7 To illustrate this embodiment, the automobile sealing strip preparation system further includes a motor 102, a driving gear 103, and a driven gear 204. The right end of the round pipe 202 is fixedly connected with the driven gear 204, and the supporting rod 104 at the right end is fixedly connected with the motor 102 , the output shaft of the motor 102 is fixedly connected with a driving gear 103 , and the driving gear 103 is meshed with a driven gear 204 for transmission. The motor 102 can drive the driven gear 204 to rotate through the driving gear 103, and then drive the heat-resistant rubber cylinder 2 to rotate. After the sealing strip is solidified, the heat-resistant rubber cylinder 2 is rotated to avoid adhesion between the heat-resistant rubber cylinder 2 and the sealing strip. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com