Full-variable-frequency pulverizing system without minimum coal quantity limitation and debugging method

A pulverizing system and frequency conversion technology, applied in grain processing and other directions, can solve the problems of severe vibration of coal mills and damage to equipment, and achieve the effect of ensuring safe and stable operation and eliminating combustion instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing.

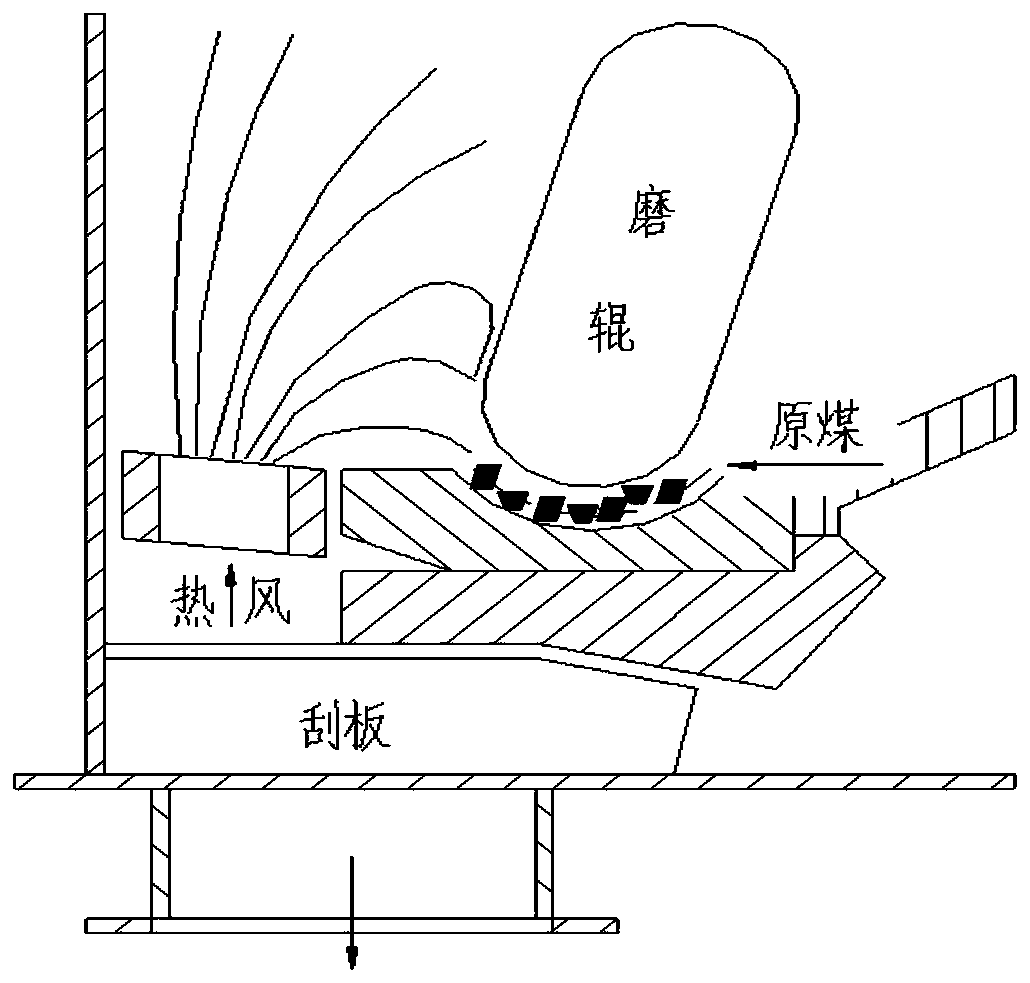

[0025] refer to image 3 , a fully variable-frequency pulverizing system with no limit on the minimum amount of coal, including a raw coal bunker 6, which is connected to a belt coal feeder 7 through a lower coal pipe 5, and the belt coal feeder 7 is connected to a roller through a coal drop pipe 8 on the millstone of the coal mill 9; the millstone of the roller mill 9 is driven to rotate by the mill motor 1 through the reducer, and the speed of the mill motor 1 is regulated by the coal mill frequency converter 2; and then adjusted The rotating speed of the grinding disc adjusts the size of the grinding output; the belt coal feeder 7 is driven by the coal feeder motor 3, and the coal feeder motor 3 is controlled by the coal feeder inverter 4 to realize speed regulation. The faster the belt turns, The greater the amount of coal supplied.

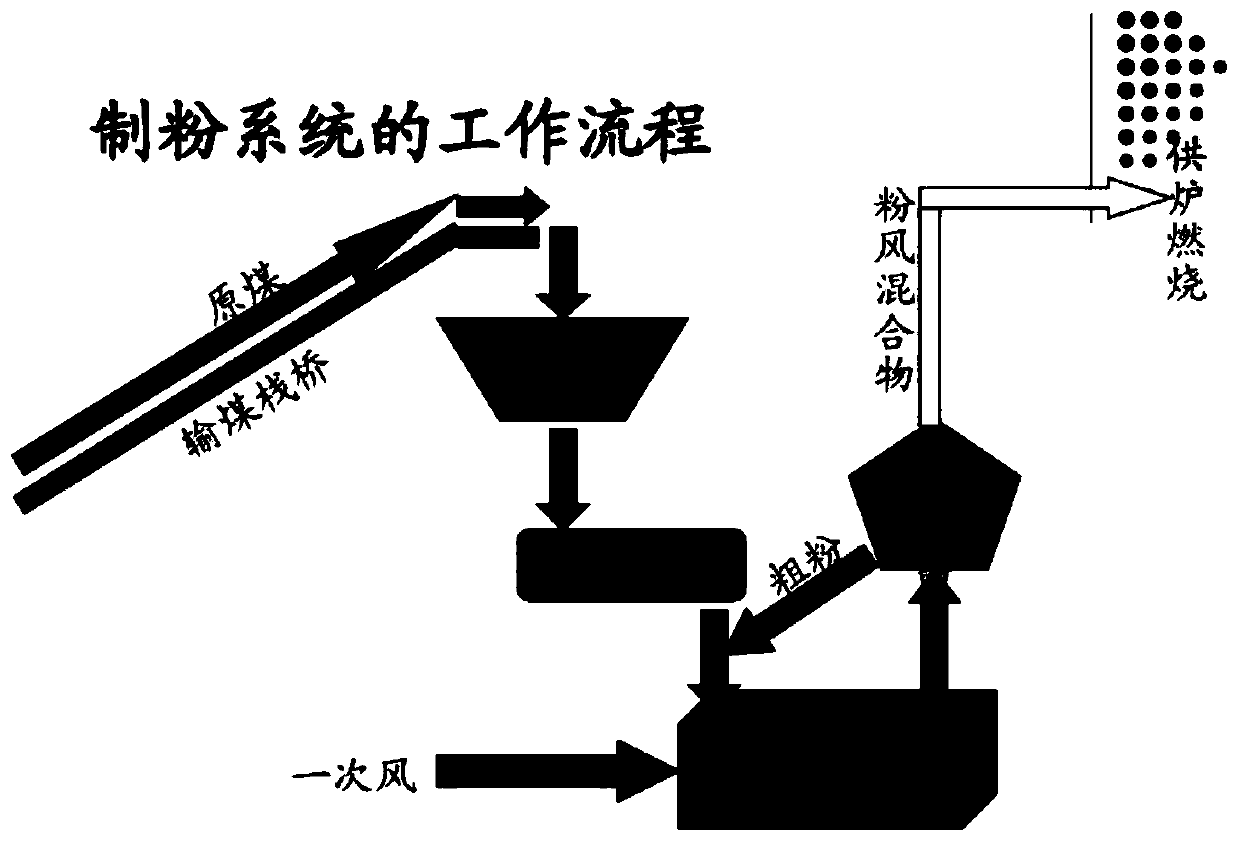

[0026]The working principle of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com