Preparation of resin microspheres of resin microspheres in printing and dyeing wastewater treatment and application thereof

A technology of resin microspheres and printing and dyeing wastewater, which is applied in textile industry wastewater treatment, water/sewage treatment, special compound water treatment, etc. It can solve the problems of low adsorption and removal efficiency of heavy metal ions and lower COD removal rate, and achieve ion diffusion resistance Small, enhances antioxidant performance, prevents oxidative degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

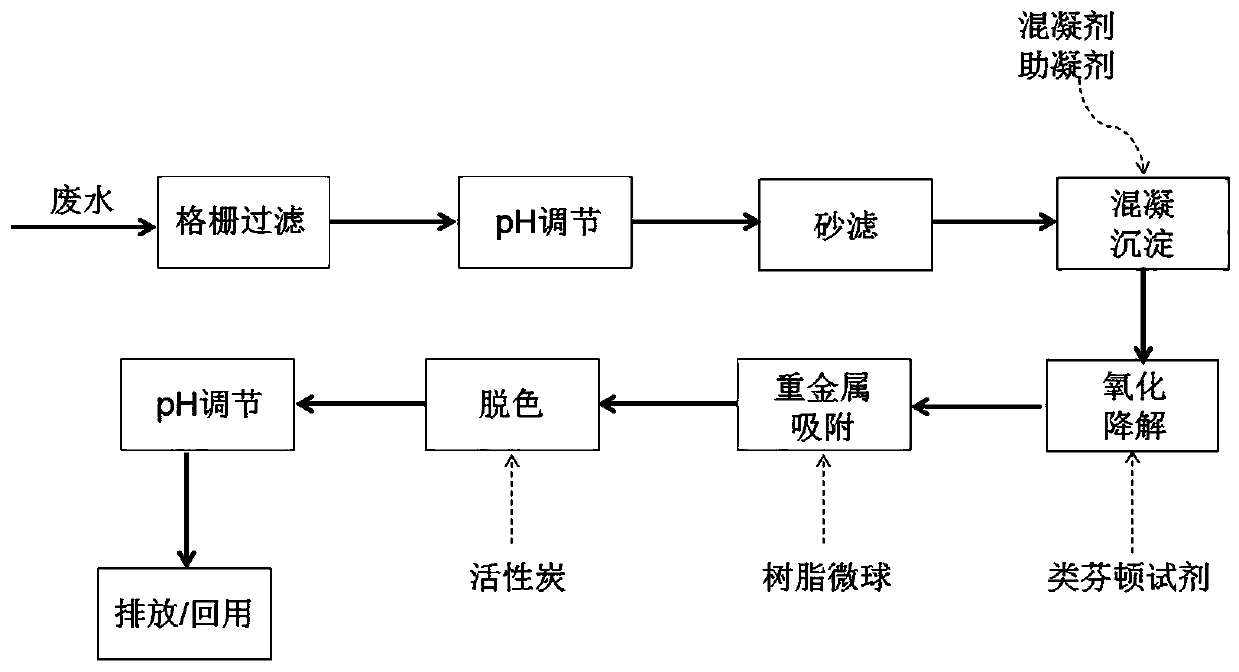

Method used

Image

Examples

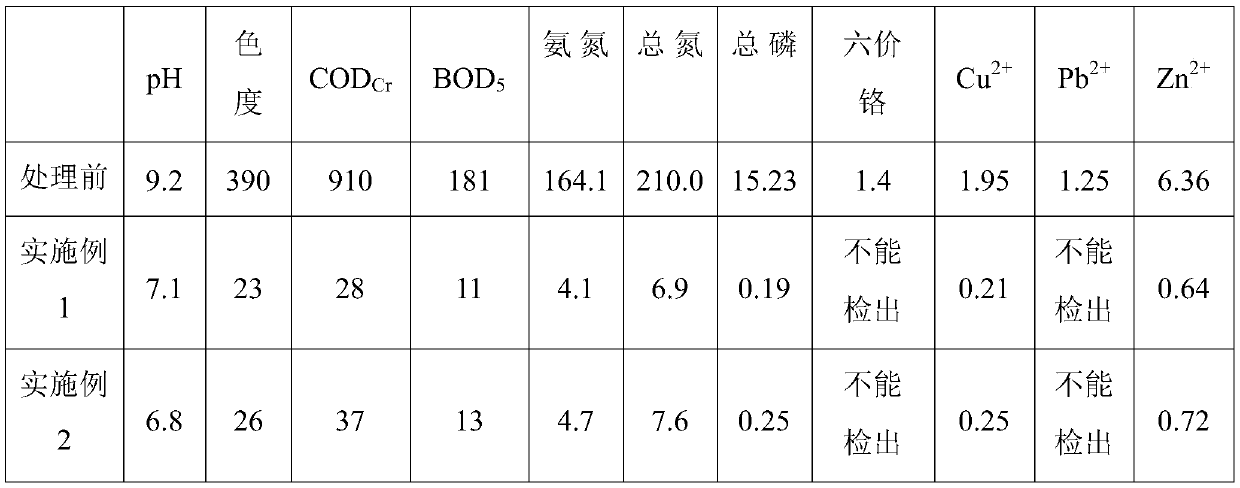

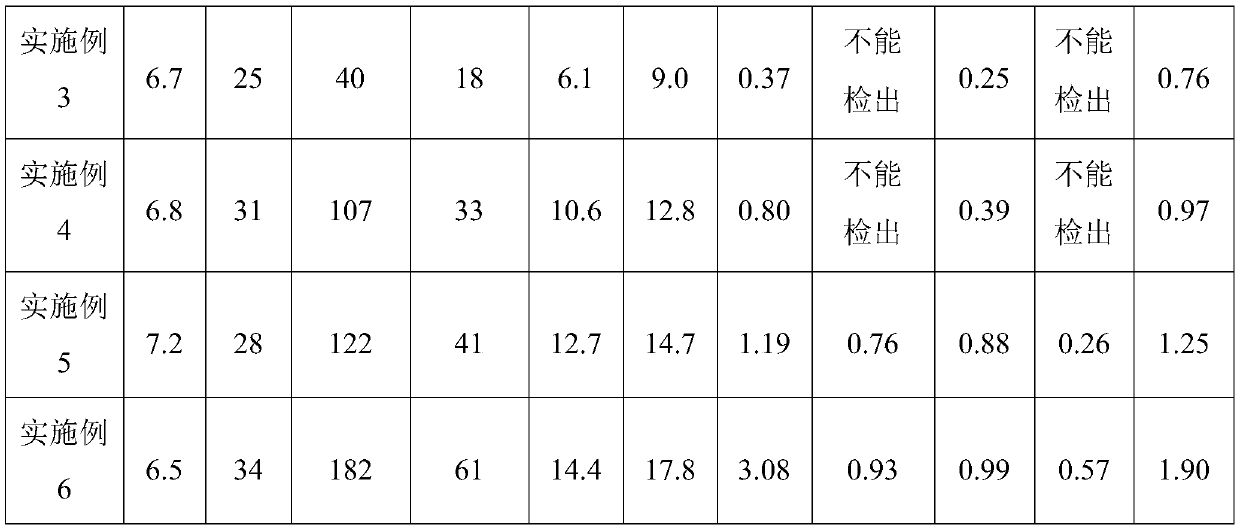

Embodiment 1

[0033] A preparation method of resin microspheres, specifically comprising the following steps:

[0034] 1) 5-chloromethyl-8-hydroxyquinoline is prepared by reacting 8-hydroxyquinoline as raw material with formaldehyde solution and concentrated hydrochloric acid;

[0035] 2) Dissolve the prepared 5-chloromethyl-8-hydroxyquinoline in acetonitrile, add N,N'-methylenebisacrylamide and potassium carbonate, 5-chloromethyl-8-hydroxyquinoline, N , The molar mass ratio of N'-methylenebisacrylamide and potassium carbonate is 4:1.5:2.0, stirred and reacted at 50°C for 20 hours, filtered while hot, filtered again and washed with distilled water to obtain alkylated The reaction product is dried for subsequent use;

[0036]3) Stir and mix hydroxyethyl methacrylate, ferulic acid, ethylene glycol dimethacrylate and deionized water, then add the alkylated product to it, heat up to 60°C, and react under nitrogen protection for 20 -30min, then add ammonium persulfate, continue to react for 20...

Embodiment 2

[0048] A preparation method of resin microspheres, specifically comprising the following steps:

[0049] 1) 5-chloromethyl-8-hydroxyquinoline is prepared by reacting 8-hydroxyquinoline as raw material with formaldehyde solution and concentrated hydrochloric acid;

[0050] 2) Dissolve the prepared 5-chloromethyl-8-hydroxyquinoline in acetonitrile, add N,N'-methylenebisacrylamide and potassium carbonate, 5-chloromethyl-8-hydroxyquinoline, N , The molar mass ratio of N'-methylenebisacrylamide and potassium carbonate is 3:1.5:2.0, stirred and reacted at 50°C for 20 hours, filtered while hot, filtered again and washed with distilled water to obtain alkylated The reaction product is dried for subsequent use;

[0051] 3) Stir and mix hydroxyethyl methacrylate, ferulic acid, ethylene glycol dimethacrylate and deionized water, then add the alkylated product to it, heat up to 60°C, and react under nitrogen protection for 20 -30min, then add ammonium persulfate, continue to react for 2...

Embodiment 3

[0063] A preparation method of resin microspheres, specifically comprising the following steps:

[0064] 1) 5-chloromethyl-8-hydroxyquinoline is prepared by reacting 8-hydroxyquinoline as raw material with formaldehyde solution and concentrated hydrochloric acid;

[0065] 2) Dissolve the prepared 5-chloromethyl-8-hydroxyquinoline in acetonitrile, add N,N'-methylenebisacrylamide and potassium carbonate, 5-chloromethyl-8-hydroxyquinoline, N , The molar mass ratio of N'-methylenebisacrylamide and potassium carbonate is 3:1.2:1.5, stirred and reacted at 50°C for 20 hours, filtered while hot, filtered again and washed with distilled water to obtain alkylated The reaction product is dried for subsequent use;

[0066] 3) Stir and mix hydroxyethyl methacrylate, ferulic acid, ethylene glycol dimethacrylate and deionized water, then add the alkylated product to it, heat up to 70°C, and react under nitrogen protection for 20 After -30 min, ammonium persulfate was added, and the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com