Shale gas well production fitting and prediction method

A technology for shale gas wells and prediction methods, which is applied in prediction, complex mathematical operations, instruments, etc., can solve the problems of large production prediction errors and cumbersome processes of shale gas wells, and achieves the effect of strong generalizability and good fitting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

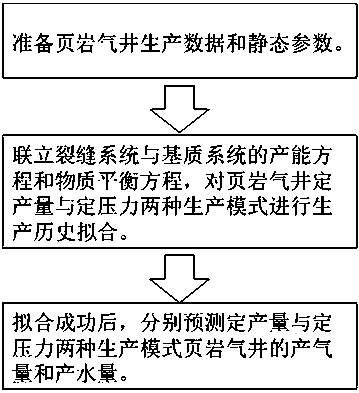

[0039] The invention provides a shale gas well production fitting and prediction method, figure 1 As the technical roadmap of this method, the method includes the following steps:

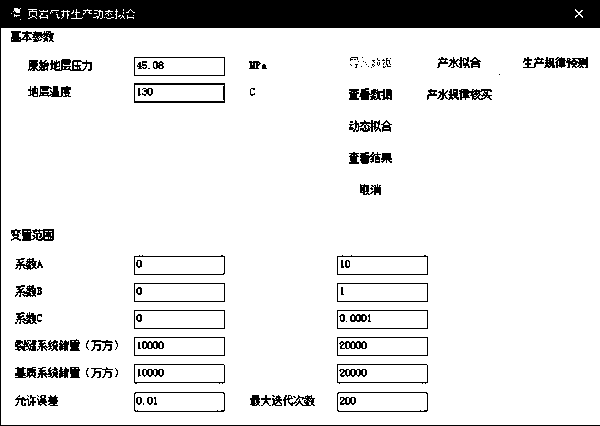

[0040] First, prepare shale gas well production data and static parameters, including gas production rate, water production rate, original pressure and current pressure of fracture system, original pressure and current pressure of matrix system, deviation coefficient under original conditions and deviation coefficient under current pressure ;

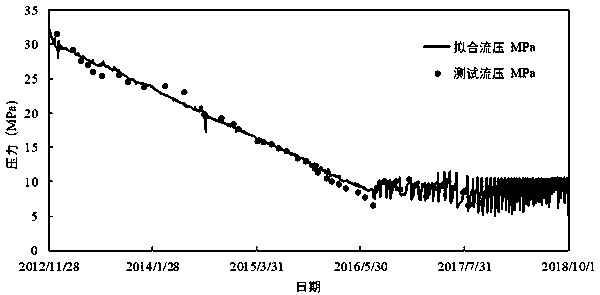

[0041] Then, the shale gas reservoir is divided into fracture system and matrix system, and the productivity equation and material balance equation of the fracture system and matrix system are combined, and the production history of shale gas wells with constant production and constant pressure is matched;

[0042] Finally, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com