An anti-drop device for bridge construction

A technology for bridge construction and fall prevention, which is applied in bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of increasing belt and motor loads, belts are easy to pull and wear, and potential safety hazards, so as to reduce load and avoid potential safety hazards , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

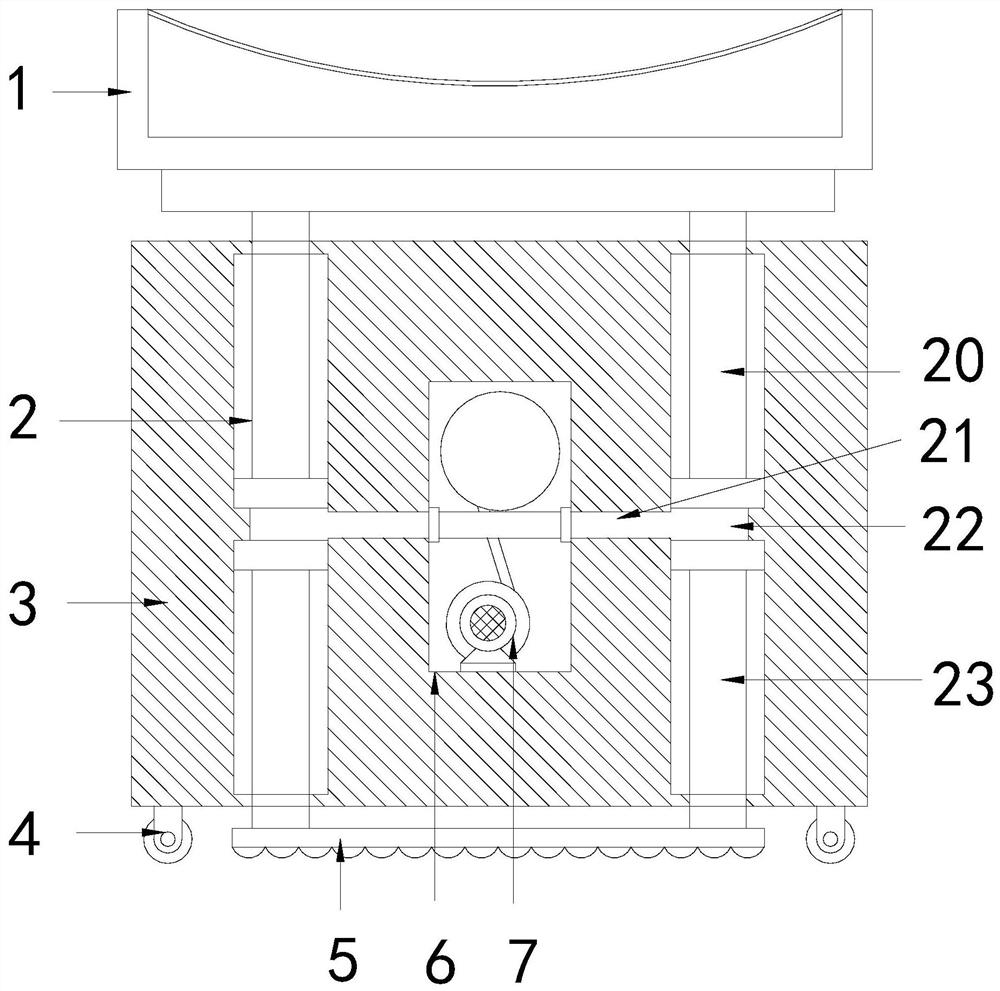

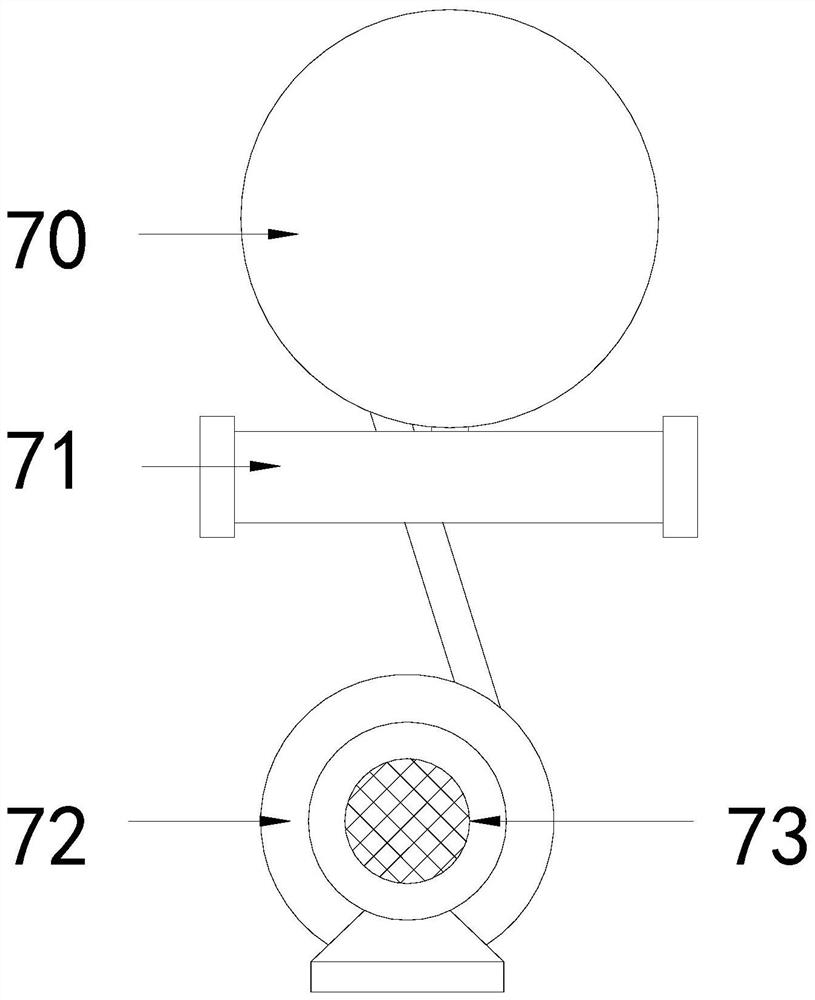

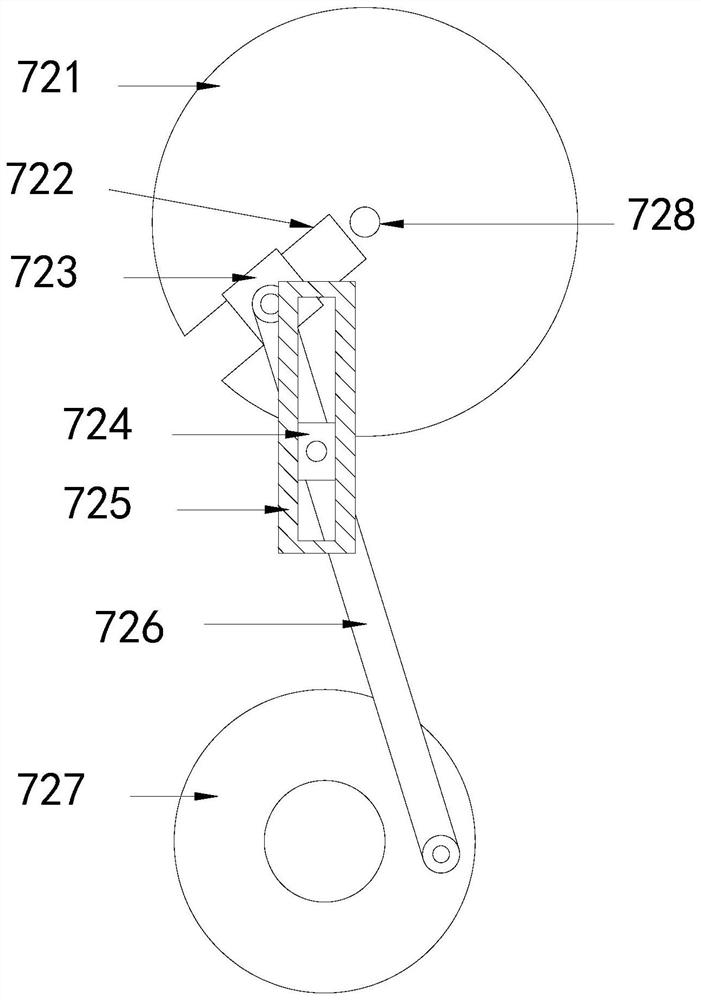

[0030] see Figure 1-5 , the present invention provides a bridge construction anti-falling device technical solution: its structure includes a net rack 1, a two-way cylinder 2, a base 3, a moving wheel 4, an anti-skid plate 5, an installation cavity 6, and a power device 7, and the bottom of the base 3 is installed There are moving wheels 4, and an installation chamber 6 is arranged in the middle of the base 3, and a power unit 7 is installed in the installation chamber 6, and the power unit 7 communicates with the two-way cylinders 2 on both sides respectively, and the two-way cylinders The top of 2 is connected with the net rack 1, the bottom of the two-way cylinder 2 is connected with the anti-skid plate 5, and the power unit 7 includes an air intake disk 70, a communication pipe 71, a transmission structure 72, and a motor 73, and the communication pipe 71 is placed horizontally In the middle of the installation cavity 6, the two ends of the communication pipe 71 are respe...

Embodiment 2

[0033] see Figure 1-7 , the present invention provides a bridge construction anti-falling device technical solution: its structure includes a net rack 1, a two-way cylinder 2, a base 3, a moving wheel 4, an anti-skid plate 5, an installation cavity 6, and a power device 7, and the bottom of the base 3 is installed There are moving wheels 4, and an installation chamber 6 is arranged in the middle of the base 3, and a power unit 7 is installed in the installation chamber 6, and the power unit 7 communicates with the two-way cylinders 2 on both sides respectively, and the two-way cylinders The top of 2 is connected with the net rack 1, the bottom of the two-way cylinder 2 is connected with the anti-skid plate 5, and the power unit 7 includes an air intake disk 70, a communication pipe 71, a transmission structure 72, and a motor 73, and the communication pipe 71 is placed horizontally In the middle of the installation cavity 6, the two ends of the communication pipe 71 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com