Water pouring device with high safety

A safety and mounting rack technology, applied in liquid flow control devices, distribution devices, special distribution devices, etc., can solve problems such as scalding hands, pouring boiling water, etc. slowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

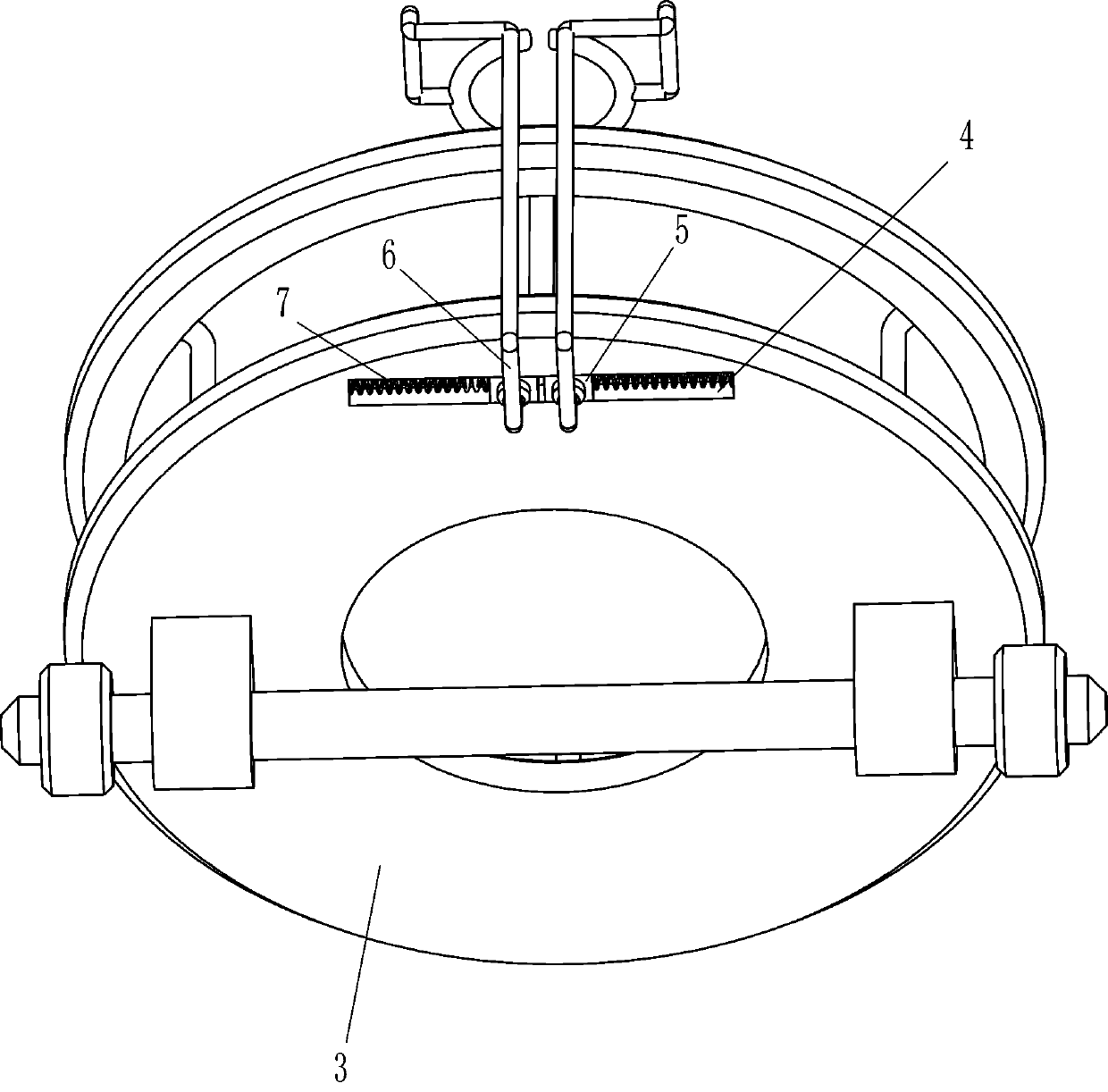

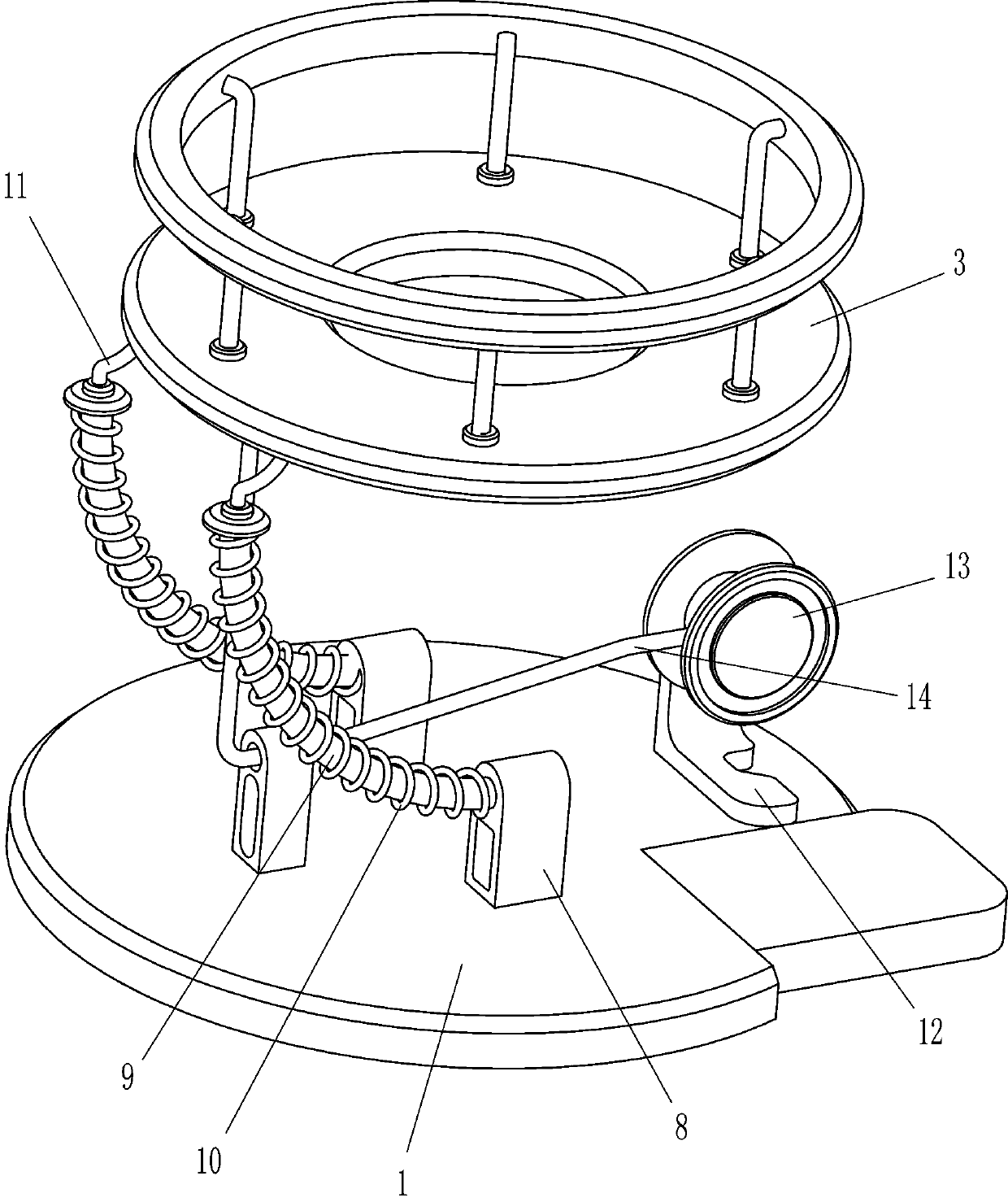

[0024] A water pouring device with high safety, such as Figure 1-6 As shown, it includes a base 1, a bracket 2, a placement frame 3, a handle fixing component, a guide component, a water cup placement component, a take-up and release line component, and a power component. 2 There is a rack 3 rotating between the tops, and a handle fixing assembly that fixes the handle by sliding is installed on the right side of the bottom of the rack 3, and a guide for pouring water into the kettle is provided between the base 1 and the rack 3 Guide assembly, the top left side of the base 1 is provided with a water cup placement assembly, the top right side of the base 1 is installed with a take-up and release line assembly through rotation, the take-up and release assembly cooperates with the guide assembly, and the top right side of the base 1 is installed with a Power components that are powered by electric motors.

[0025] Such as figure 1 and 2 As shown, the handle fixing assembly in...

Embodiment 2

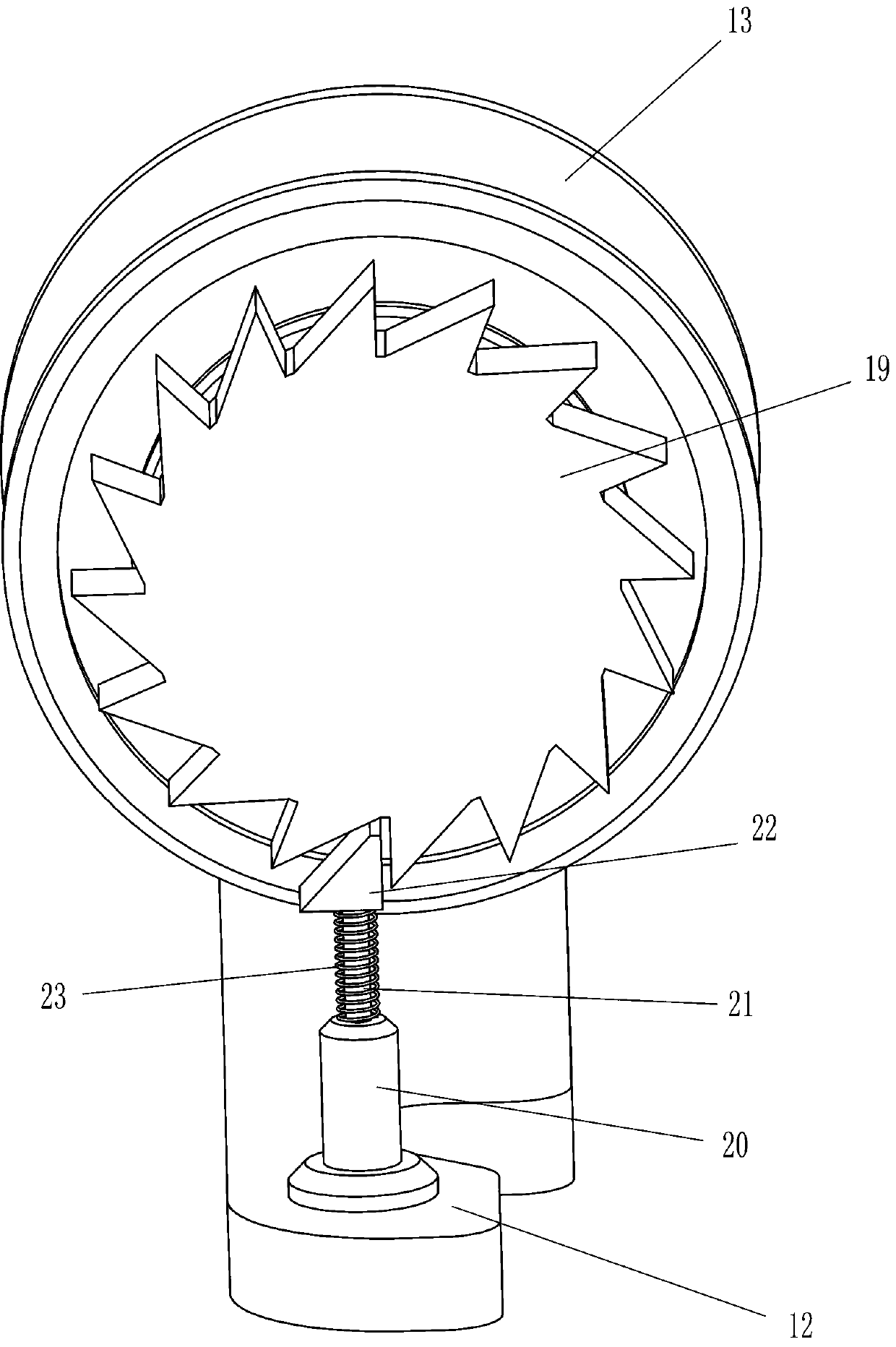

[0037] On the basis of Example 1, such as figure 1 and 7 As shown, it also includes a second sliding block 26, a special-shaped rod 27, a deceleration plate 28, a rotating rod 29, a third spring 30, a pulling rod 31 and a pressing rod 32, and the upper part of the rear side of the mounting frame 12 has a second sliding groove 25 , the left and right sides of the second sliding groove 25 are slidingly provided with a second sliding block 26, the second sliding block 26 is welded with a special-shaped rod 27, the upper end of the special-shaped rod 27 is welded with a speed reducer 28, and the rear side of the reel 13 The output shaft of the output shaft is connected with a rotating rod 29, the rotating rod 29 is located between the deceleration plates 28, the third spring 30 is welded between the second sliding blocks 26, and the bottom of the second sliding block 26 is rotatably provided with a pull rod 31, pulling A pressing bar 32 is rotatably arranged between the bottom en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com