Guiding vehicle

A guide vehicle and wheel technology, applied in the field of guide vehicles, can solve the problems of unusable, poor obstacle-crossing ability, difficult processing, etc., and achieve the effect of strong adaptability, strong obstacle-crossing and climbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

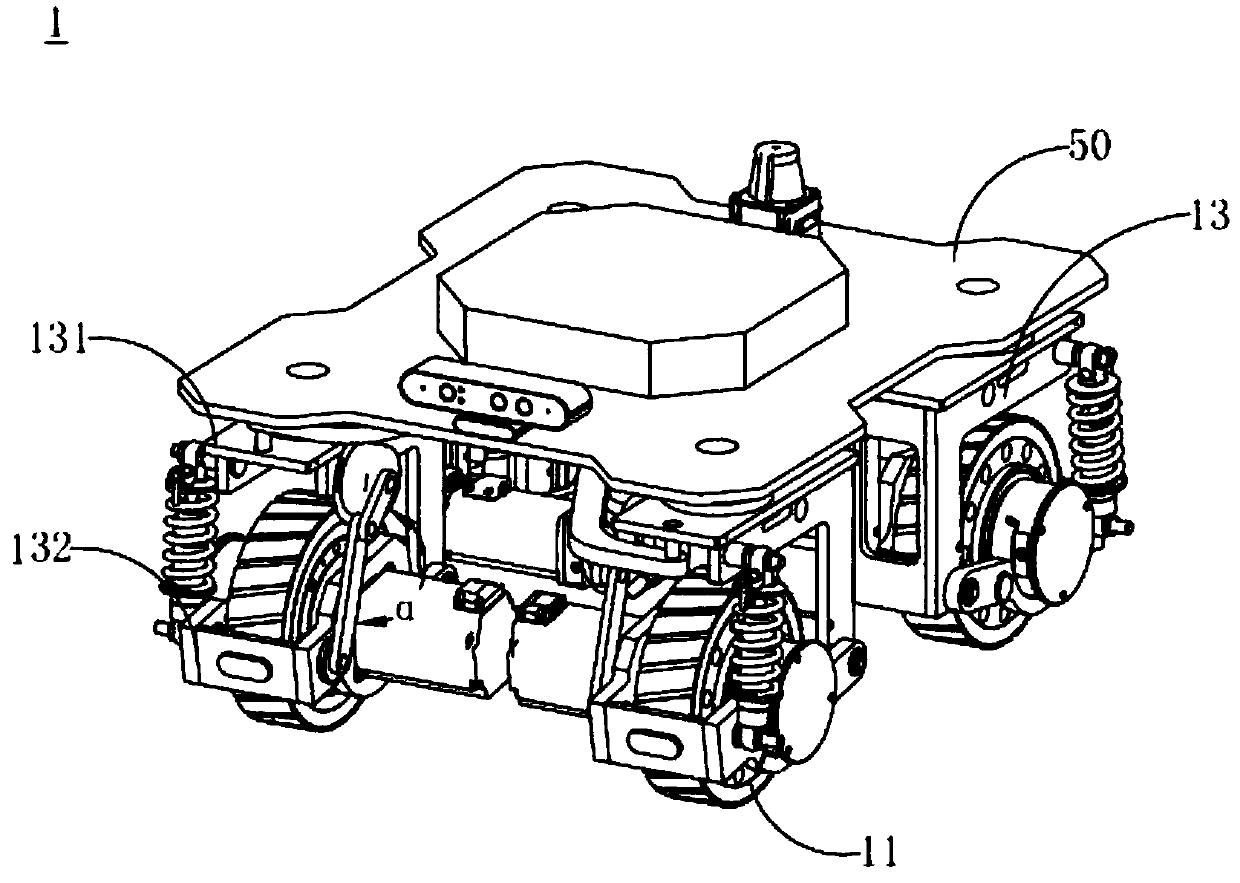

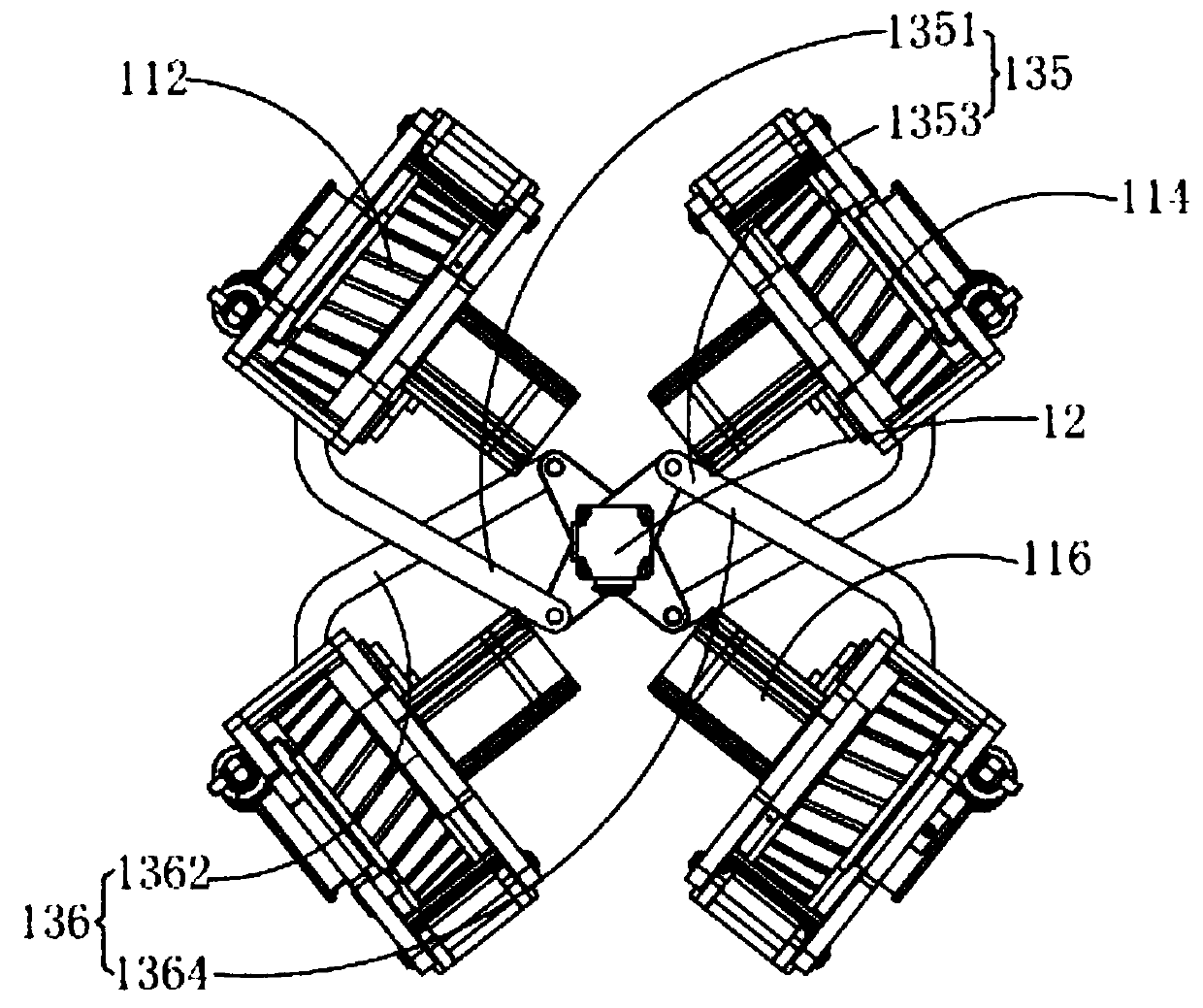

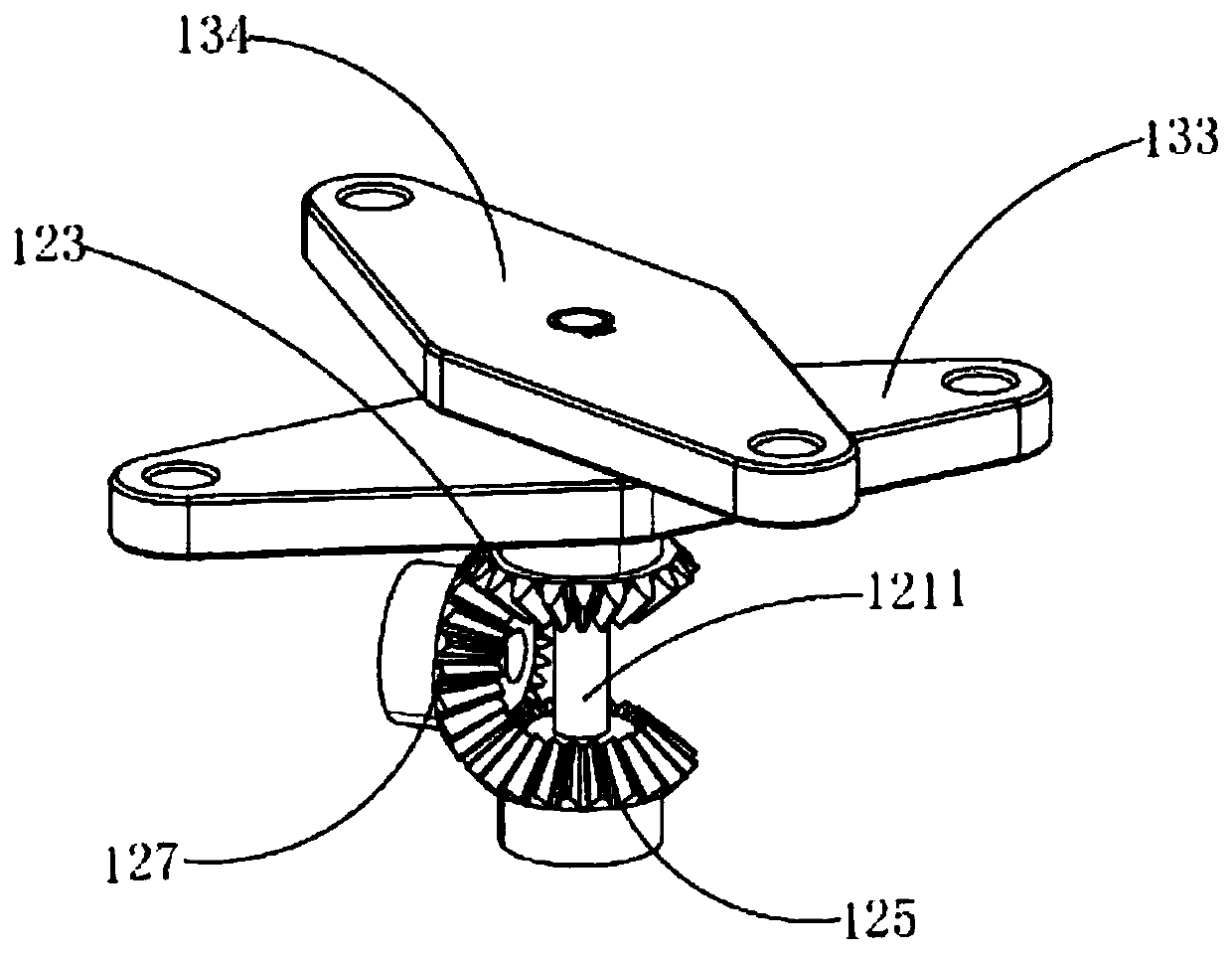

[0024] see figure 1 , figure 2 and image 3 , the present invention provides a guiding vehicle 1 , including a wheel system 11 , a first transmission mechanism 12 and a second transmission mechanism 13 . The wheel system 11 includes a first wheel set 112 and a second wheel set 114; the first transmission mechanism 12 includes a steering motor 121, a first gear 123 and a second gear 125, and the steering motor 121 drives the first gear 123 and the second gear 125 along the Rotate in the opposite direction; the second transmission mechanism 13 is mechanically connected between the first transmission mechanism 12 and the wheel system 11, the first gear 123 drives the first wheel set 112 to rotate through the second transmission mechanism 13, and the second gear 125 passes through the second The transmission mechanism 13 drives the second wheel set 114 to rotate.

[0025] see figure 2 and Figure 4 , in this embodiment, the first wheel set 112 includes a first driving wheel...

no. 2 example

[0052] see Figure 6 , Figure 7 and Figure 8 , different from the first embodiment, the second transmission mechanism 23 of the guide car 2 provided by the present application includes a guide rail 231, a first screw mandrel 232, a second screw mandrel 233, a first slider 234, and a second slider 235 , the first support block 236 and the second support block 237 . The first wheel set 212 includes a first driving wheel 2121 and a second driving wheel 2123, and the first wheel set 212 may be an omnidirectional wheel set. The second wheel set 214 includes a third drive wheel 2142 and a fourth drive wheel 2144 . The second wheel set 214 can be a differential drive wheel set, so that the center of rotation of the guide vehicle 2 can be set on the connecting line between the third drive wheel 2142 and the fourth drive wheel 2144, so that the lateral force during the correction process Changing from sliding friction to rolling friction overcomes the negative influence of latera...

no. 3 example

[0065] see Figure 10 and Figure 11 , different from the first embodiment, the first transmission mechanism 32 of the guide vehicle 3 provided by the present application does not include a third gear, and the first gear 323 and the second gear 325 mesh with each other, and the steering motor 321 and the first gear 323 Mechanically connected to drive the first gear 323 to rotate, and then to drive the second gear 325 to rotate.

[0066] The first gear 323 and the second gear 325 mesh with each other, and the first gear 323 and the second gear 325 are located on the same plane, that is, both are located between the first turning plate 333 and the second turning plate 334 . The first turning plate 333 is fixedly connected with the first gear 323, and the second turning plate 334 is fixedly connected with the second gear 325. Those skilled in the art can understand that the rotation directions of the two gears meshing with each other are opposite, so the first turning plate 333 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com