Device and method for automatically detecting flatness of surfaces of circuit boards

An automatic detection device, a technology for surface flatness, which is used in measurement devices, instruments, sorting and other directions, can solve the problems of a single circuit board affecting detection accuracy, unfavorable continuous detection of circuit boards, and inconvenient positioning of circuit boards. The effect of taking, improving ability and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

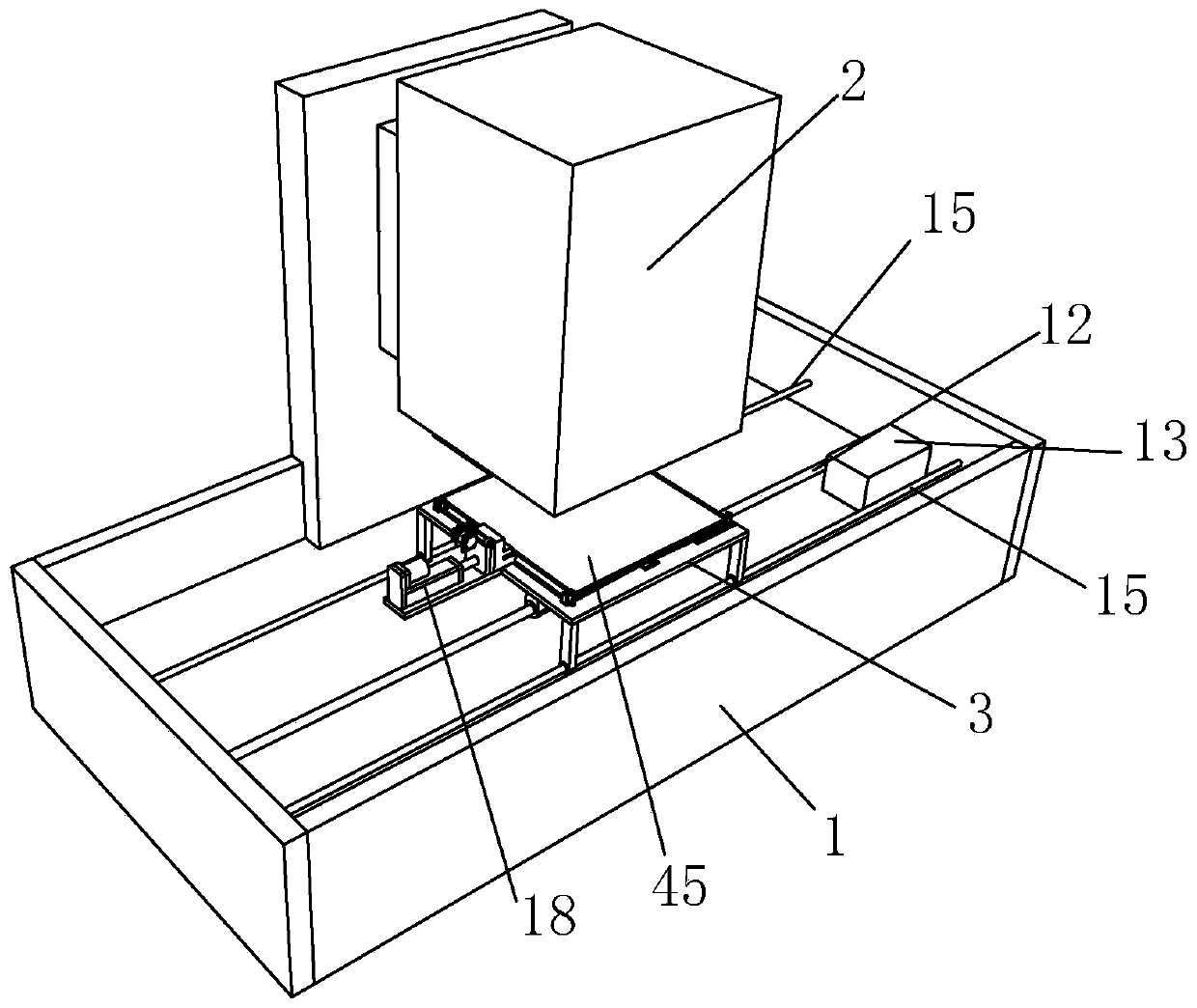

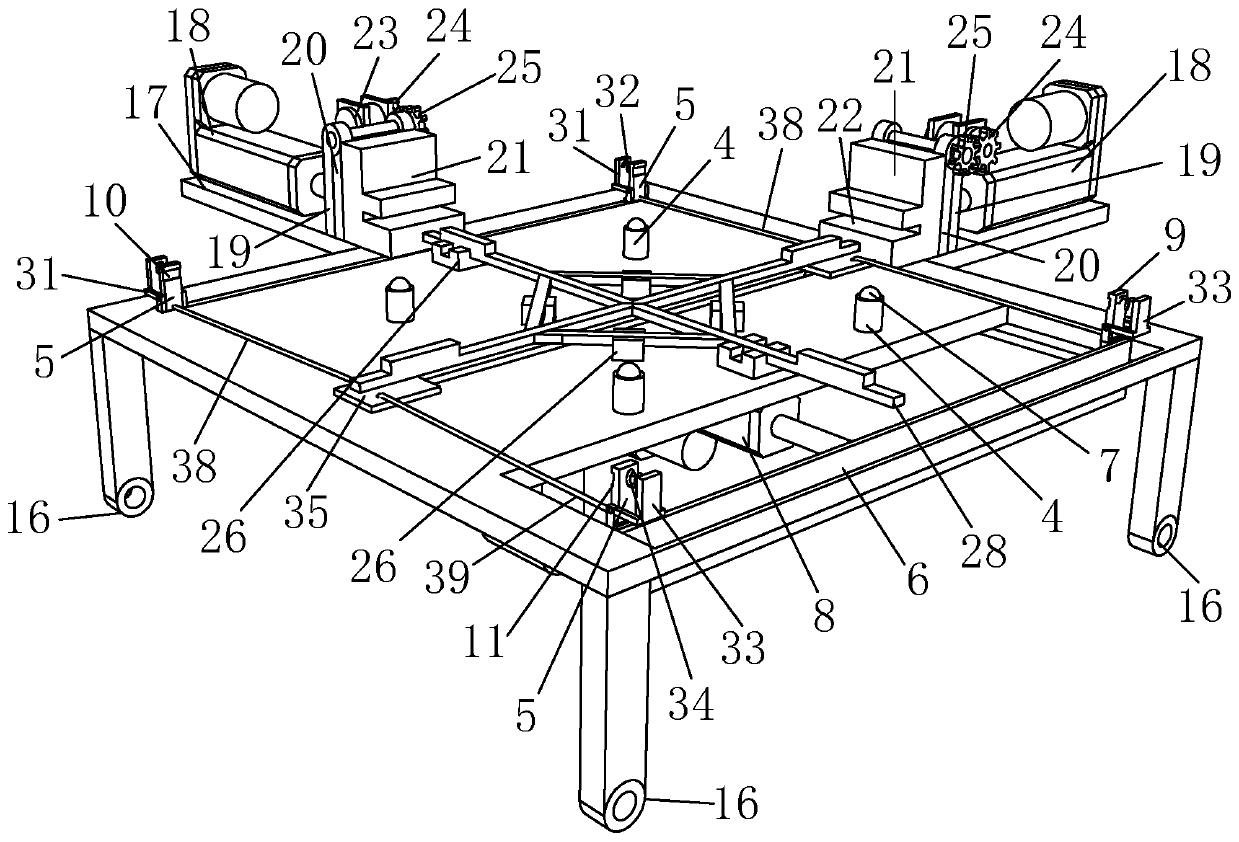

[0034] Such as Figure 1 to Figure 7 As shown, it is an automatic detection device for circuit board surface flatness of the present invention, including a detection platform 1 and a detection mechanism 2, the detection mechanism 2 is set on the detection platform 1, the detection platform 1 is provided with a detection seat, and the detection seat 3 is provided with a support Rod 4, first block 5 and slide bar 6, ball 7 is provided on the top of support bar 4, first block 5 is fixedly connected with detection seat 3, slide bar 6 is slidably connected with detection seat 3, and detection seat 3 is provided with The first electric push rod 8, the first electric push rod 8 is fixedly connected with the slide bar 6, the slide bar 6 is provided with a second block 9, the first block 5 is provided with a first positioning groove 10, and the second block 9 A second positioning groove 11 is provided, and the height of the first positioning groove 10 and the second positioning groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com