Method and device for filling containers with carbonised filling material and subsequently closing the filled containers

A filling and container technology, which is applied in the direction of closing the container tightly with a lid, closure, packaging item type, etc., can solve the problems of high structural design costs, and achieve the effect of minimizing the risk of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The basic structure of machines for filling containers or for simultaneously forming and filling containers from preforms is sufficiently known from the prior art. In order to avoid repetitions, reference is made to DE 10 2010 007 541 A1 with respect to the forming and filling machine, especially to paragraphs [0028] to [0065] there and to the figure 1 to 8. In this regard, only the features that are essential to the invention are described below.

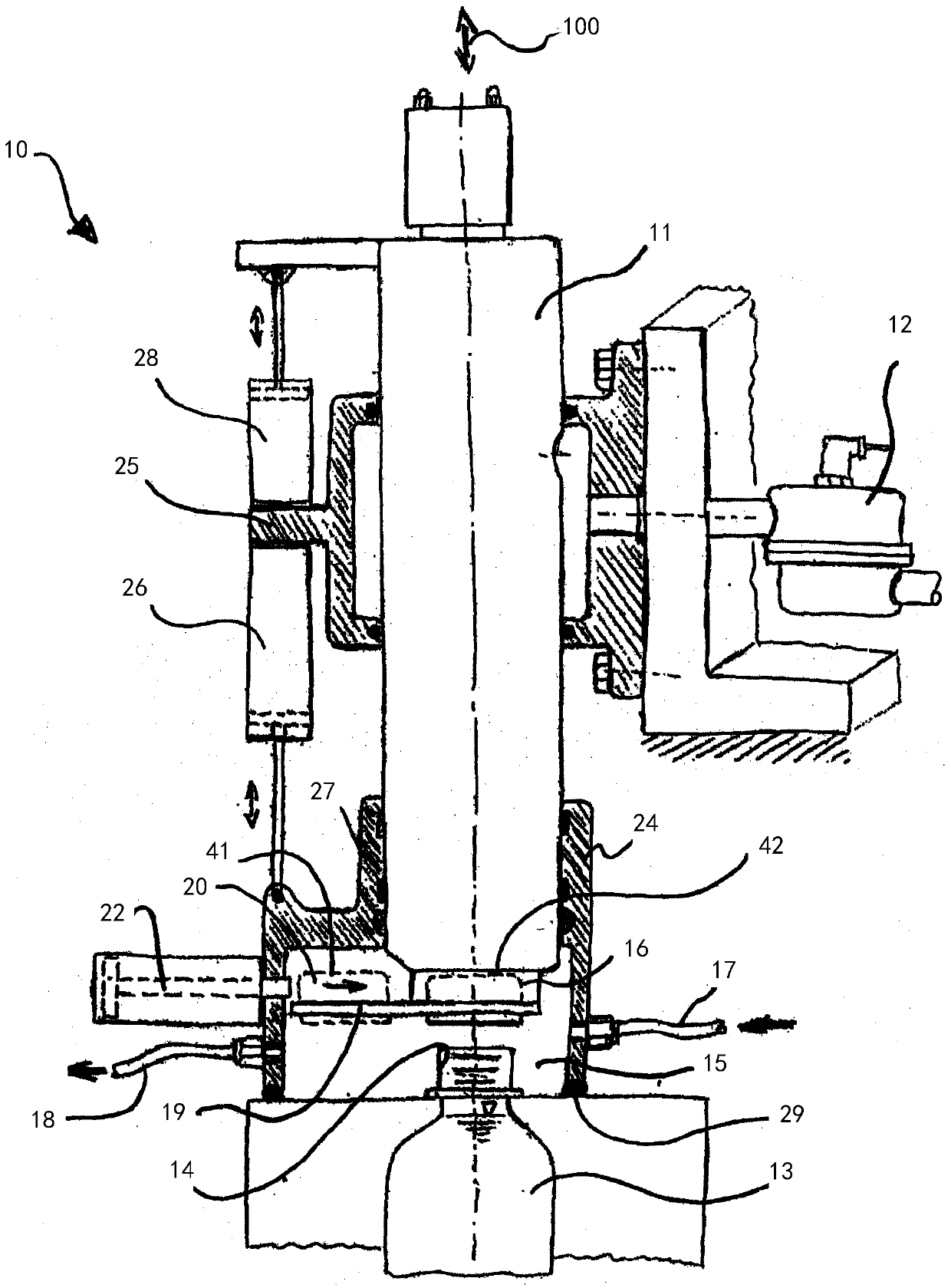

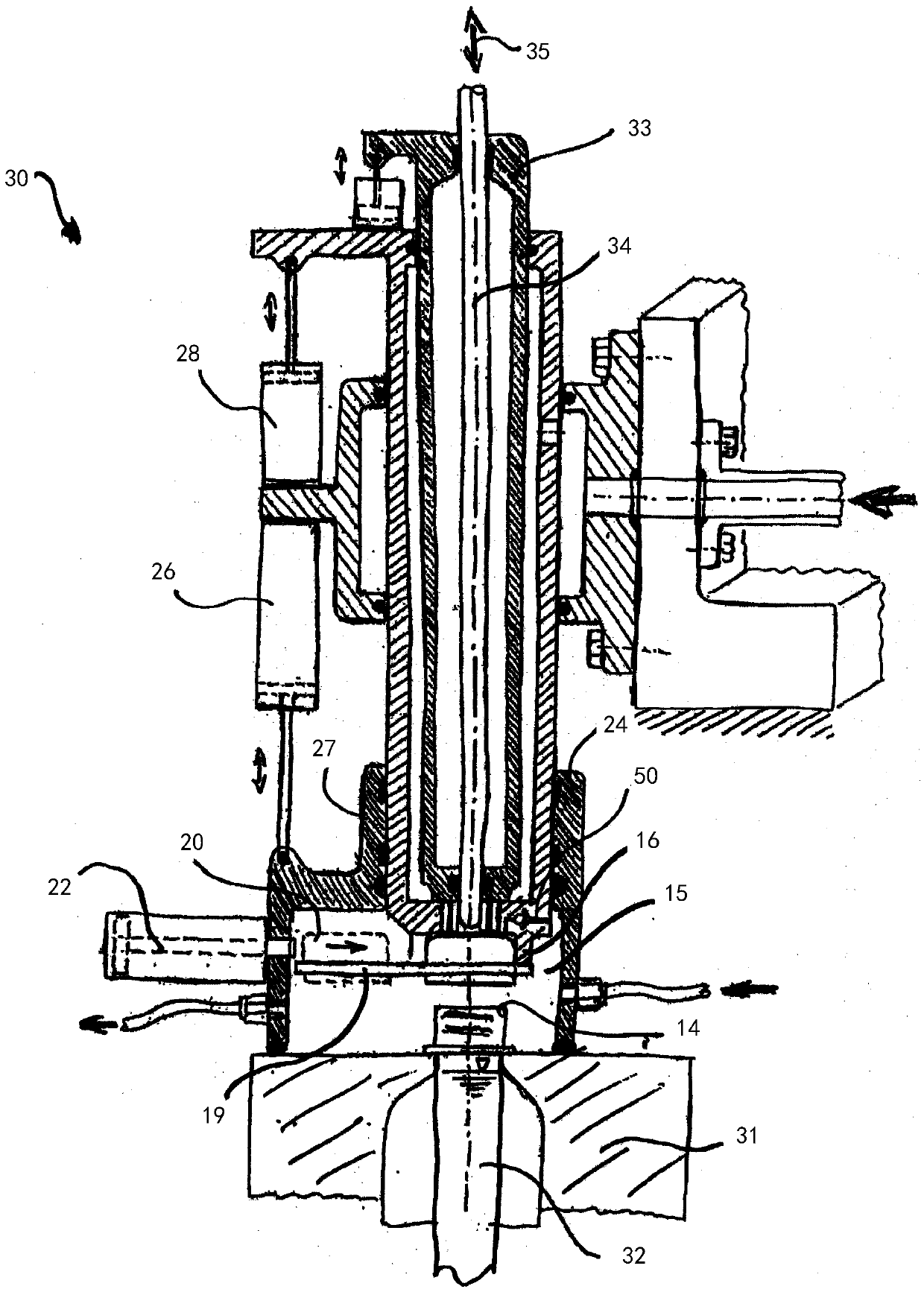

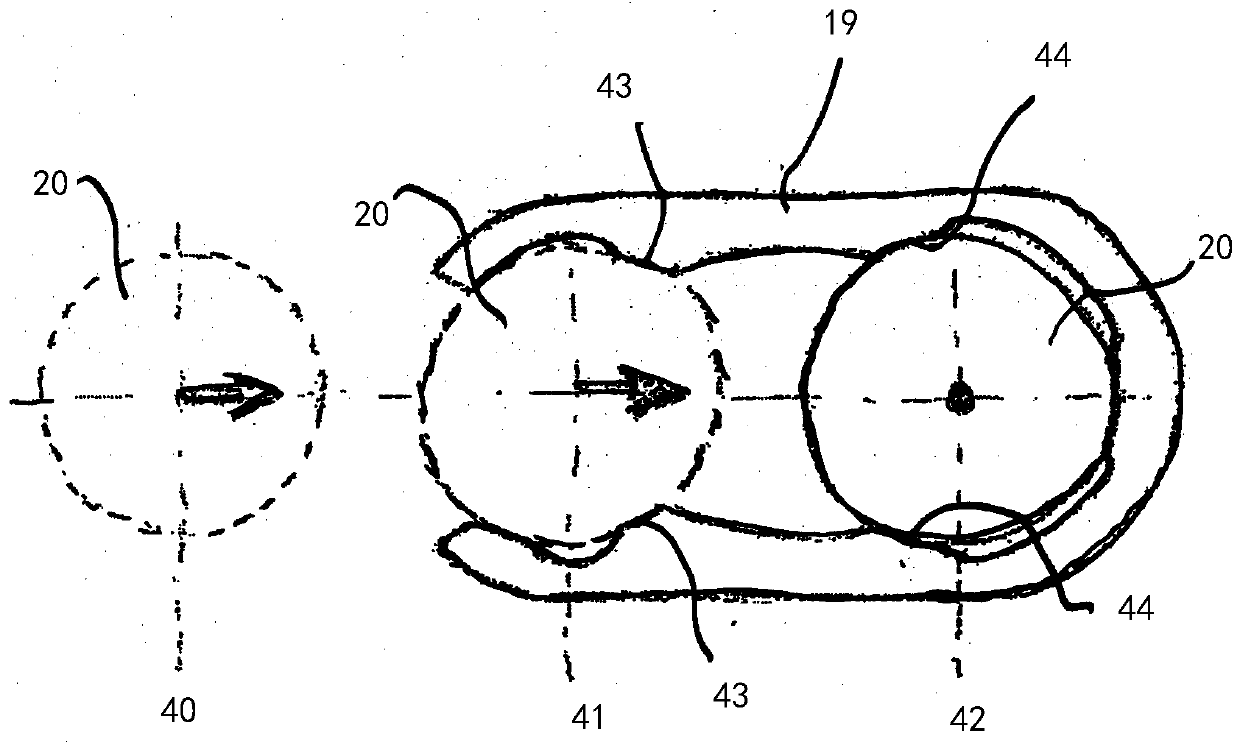

[0037] figure 1 A schematic illustration of a filling station 10 is shown with a filling head 11 arranged displaceably in the axial direction, which can be loaded with a filling product to be filled via a feed line 12 . Furthermore, a container 13 is shown, which is arranged in its filling position. Inside the pressure chamber 15 is located the container opening 14 which is aligned with the filling head side. The pressure chamber 15 surrounds both the container opening 14 and the end 16 of the filling head 11 facing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com