Four-electrode conductivity adjustable temperature sensor

A temperature sensor, four-electrode technology, applied in thermometers, thermometer parts, thermometers using directly heat-sensitive electrical/magnetic components, etc., can solve problems such as measurement deviation of thermal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

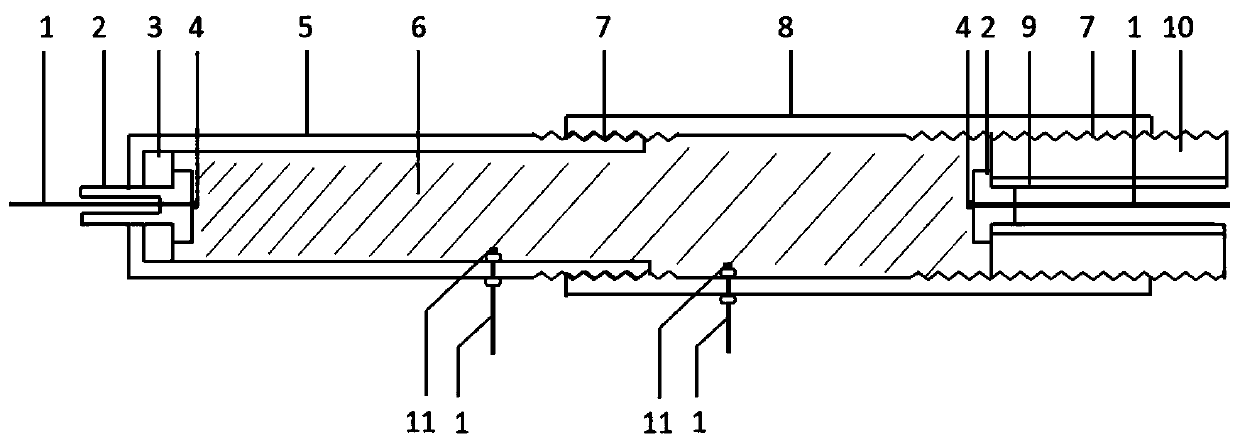

[0012] figure 1 It is a structural diagram of the four-electrode conductance adjustable temperature sensor involved in the present invention. The main structure of the temperature sensor involved in this embodiment includes a wire 1, an electrically insulating rubber fixing rod 2, an electrically insulating rubber gasket 3, two current electrodes 4, two threaded housings 5 and 8, with a known conductivity (or resistance) ) Liquid 6, adjustable screw 7, electrically insulated inner wall 9, adjusting rod 10, two voltage electrodes 11.

[0013] The current electrode 4 is fixed on the left side of the housing 5 by an electrically insulating rubber fixing rod 2 and is led out by a wire 1. The right current electrode 4 located in the housing 8 is fixed on the adjusting rod 10 by an electrically insulating rubber fixing rod 2 and is led out of the housing by a wire 1. The housing 5 and the housing 8 are assembled and connected by an adjustable screw 7. There is a voltage electrode 1...

Embodiment 2

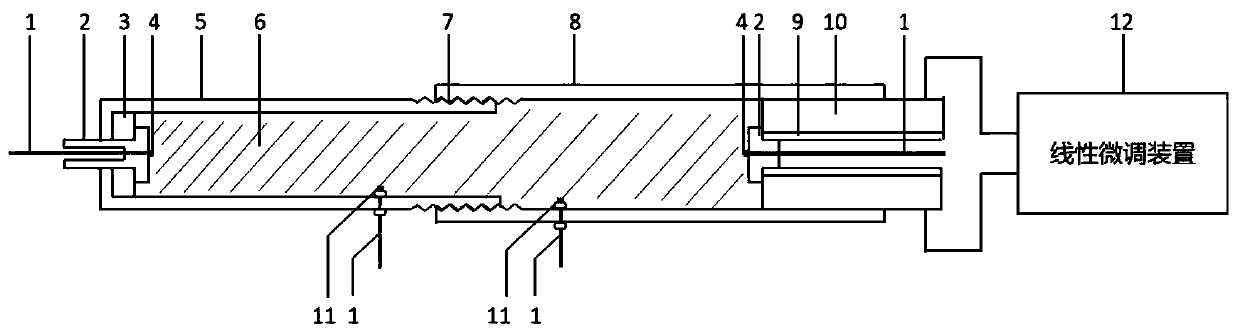

[0015] Such as figure 2 It is a schematic diagram of the automatic adjustment of a four-electrode conductance adjustable temperature sensor. The adjusting rod 10 is connected to the linear fine-tuning device 12 and is driven by the fine-tuning device, so that the adjusting rod is translated inside and outside the housing, so as to adjust the thread pitch of the screw 7 to make The resistance value is accurately adjustable. In addition to fixing electrodes and wires, the electrically insulating rubber fixing rod 2 and the electrically insulating rubber gasket 3 also have the function of absorbing external pressure and vibration, and protecting the electrodes from deformation due to external pressure. The conductive liquid 6 and the rubber ring 3 ensure that the liquid conductance between the two electrodes is not affected by external pressure, but is only related to temperature. A constant current source current is applied between the two electrodes, and the voltage drop betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com