Plate-type sliding layer support and construction method thereof

A plate type, sliding layer technology, applied in bridge parts, erection/assembly of bridges, bridge materials, etc., can solve the problems of limited service life of bearing maintenance plans, unfavorable railway safety operation, inconsistent roller shaft inclinations, etc., to reduce later maintenance. Maintenance cost, wide applicability, good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

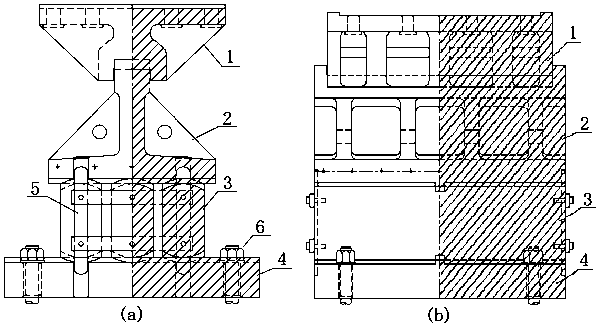

[0044] The utility model relates to a plate-type sliding layer bearing, which comprises an upper swing structure, a middle sliding layer structure and a base 4. The swing structure is composed of matching upper swing 1 and lower swing 2 (following the swing structure of the original roller bearing), and the swing direction is along the bridge;

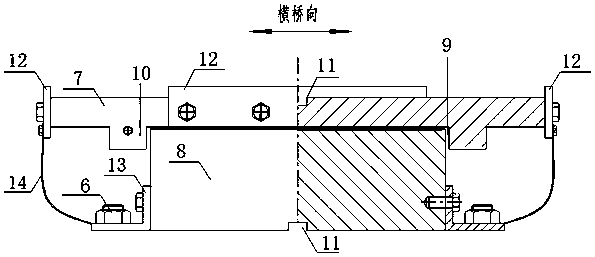

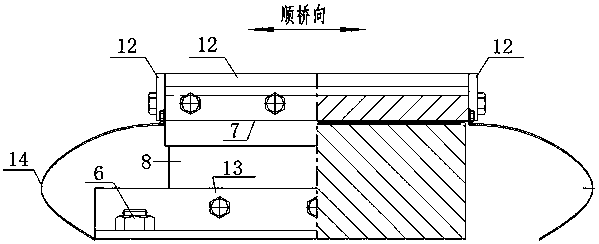

[0045] The sliding layer structure is composed of matching upper bearing plate 7 and lower bearing plate 8; the upper bearing plate 7 is plate-shaped, the top surface and the bottom surface are both flat, and the top surface is provided with a limit card that matches the limit beam on the bottom surface of the hem 2 The groove 11 is provided with a pair of crossbeams 10 on the bottom surface, and the chute 9 matching the top of the lower bearing plate 8 is formed between the crossbeams 10, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com