A kind of degradable medical material and preparation method thereof

A raw material, silicone rubber technology, applied in the field of degradable medical materials and their preparation, can solve the problems of cracking and brittleness, and achieve the effect of expanding the application field, reducing the shrinkage rate, and improving the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

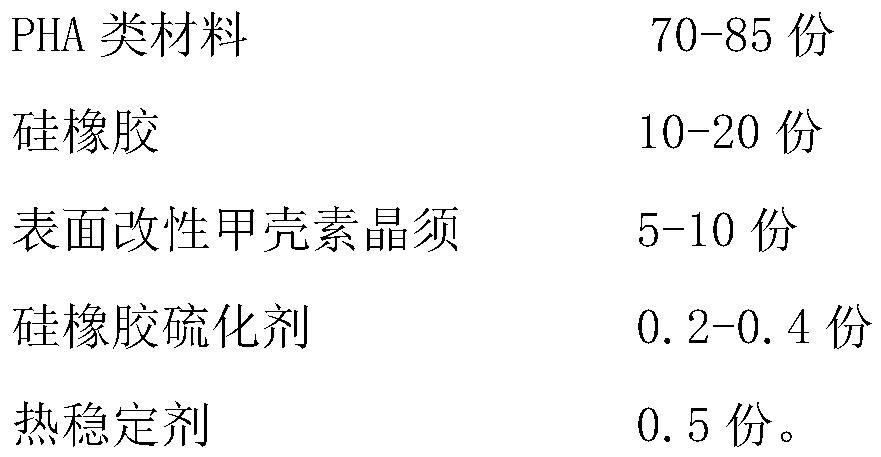

Method used

Image

Examples

Embodiment 1

[0028] The poly-β-hydroxybutyric acid 85 parts, silicone rubber 10 parts, heat stabilizer 0.5 parts added to the vacuum mixer, mixed evenly for 1min, and then added surface modified chitin whiskers to it 5 parts, continue to mix for 1min, and finally add 0.2 parts of silicone rubber vulcanizer to it after 5 minutes of mixing can be opened, or by pulling strips through the mouth mold to obtain degradable medical materials. Among them, the processing temperature of the mixer is 200 °C, the pressure of the upper pressure is 0.65MPa, and the screw speed of the mixer is 30r / min.

Embodiment 2

[0030] The β-hydroxybutyric acid and β-hydroxyvaleric acid copolymer 77 parts, silicone rubber 15 parts, heat stabilizer 0.5 parts added to the vacuum mixer, mixed evenly for 2 min, and then added surface modified chitin whisker 8 parts, continue to mix for 2 min, and finally add 0.3 parts of silicone rubber vulcanizer to it after 7 minutes of mixing, or by granulation of the mold strip to obtain degradable medical materials. Among them, the processing temperature of the mixer is 195 °C, the pressure of the upper pressure is 0.65MPa, and the screw speed of the mixer is 40r / min.

Embodiment 3

[0032] 70 parts of polyhydroxybutyrate, 20 parts of silicone rubber, 0.5 parts of heat stabilizer are added to the vacuum mixer, mixed evenly for 3min, and then added to it 10 parts of surface modified chitin whiskers, continue to mix for 3min, and finally add 0.4 parts of silicone rubber vulcanizer to it after 10 minutes of mixing, or through the mouth mold strip granulation to obtain degradable medical materials. Among them, the processing temperature of the mixer is 190 °C, the pressure of the upper pressure is 0.65MPa, and the screw speed of the mixer is 50r / min.

[0033] The properties of the degradable medical material prepared in Examples 1-3 are shown in Table 1 below:

[0034] Table 1

[0035] Test projects / units Test standards Example 1 Example 2 Example 3 Density / g / cm 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com