Wooden frame and production technology thereof

A technology of wooden frame and planting trough, which is applied to wood processing equipment, gardening, manufacturing tools, etc., and can solve the problem of not being able to adapt to the placement of flower pots

Active Publication Date: 2020-08-04

福州希达木业有限公司

View PDF15 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, due to the fixed overall structure of the wooden frame, only flower pots of a fixed size or smaller flower pots can be placed, and it cannot be adapted to the placement of flower pots with a diameter slightly larger than the width of the planting tank, and there is room for improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0065] A production process of a wooden frame, used to produce the wooden frame of the first embodiment, includes the following specific steps:

[0066] S1. Ingredients, support frame 1 and planting trough 2 are made by cutting and planing;

[0067] S2, painting, spray paint on the outer surface of support frame 1 and planting tank 2;

[0068] S3. Assemble, fix the planting slot 2 and the support frame 1 with screws.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

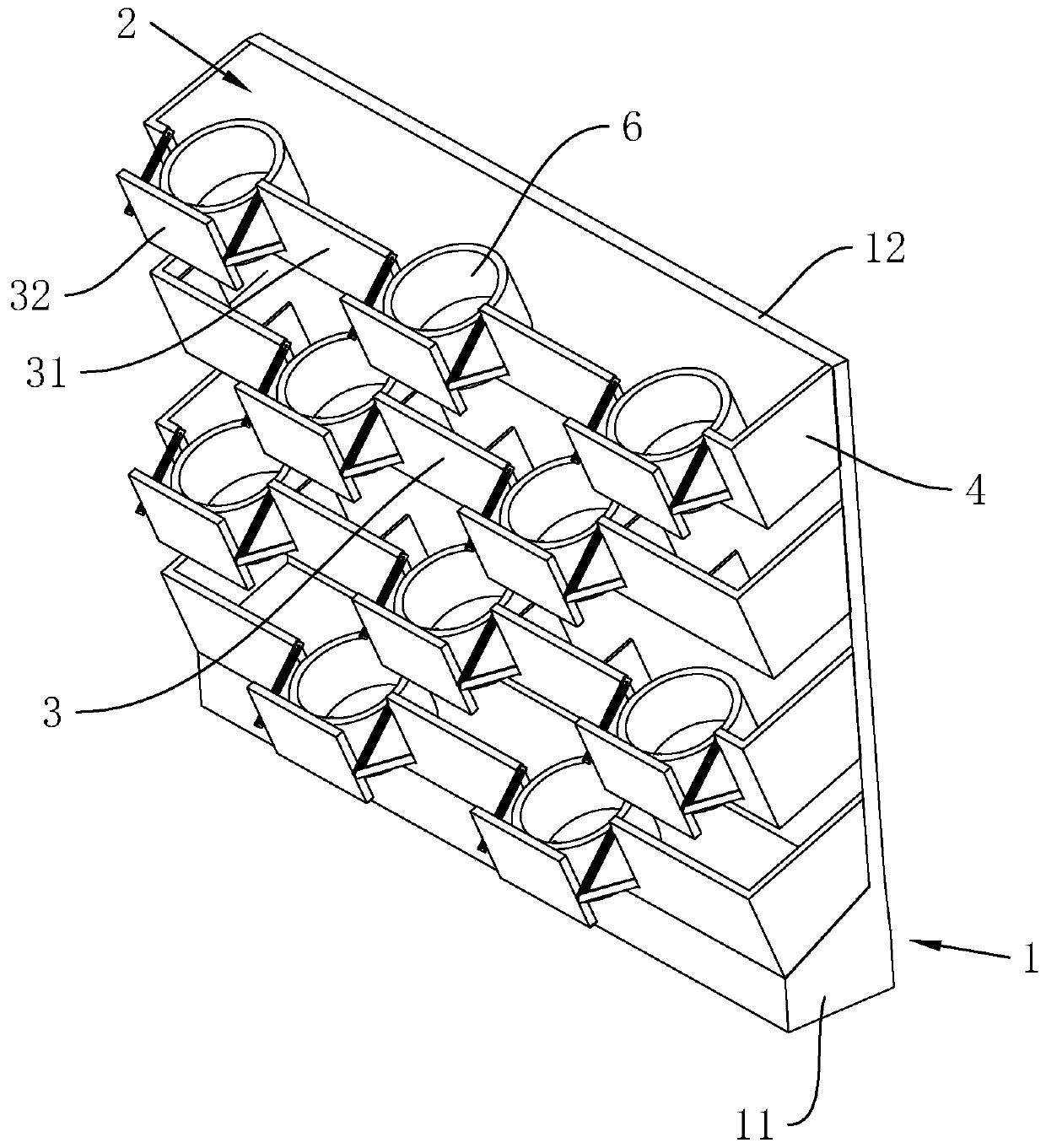

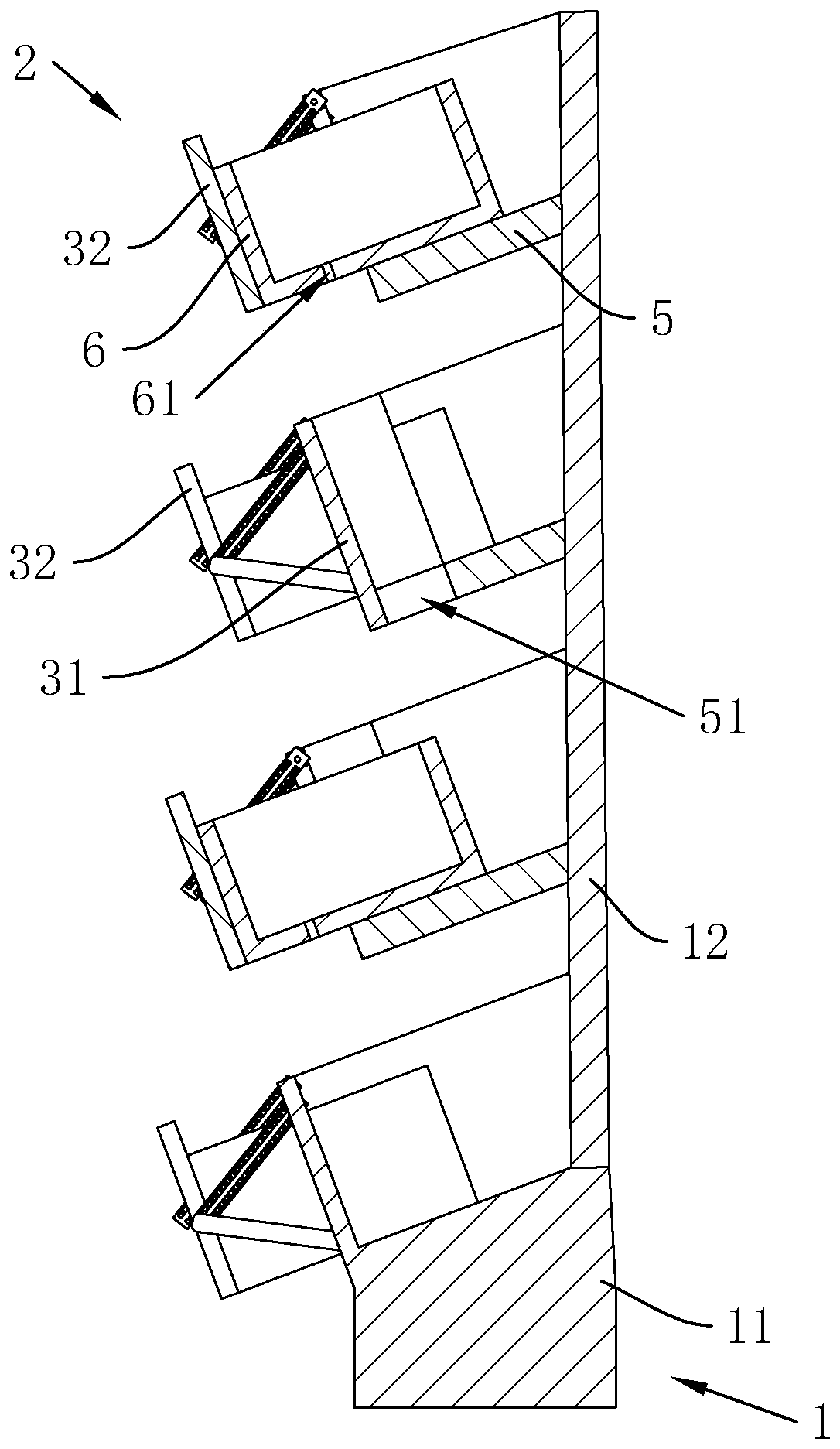

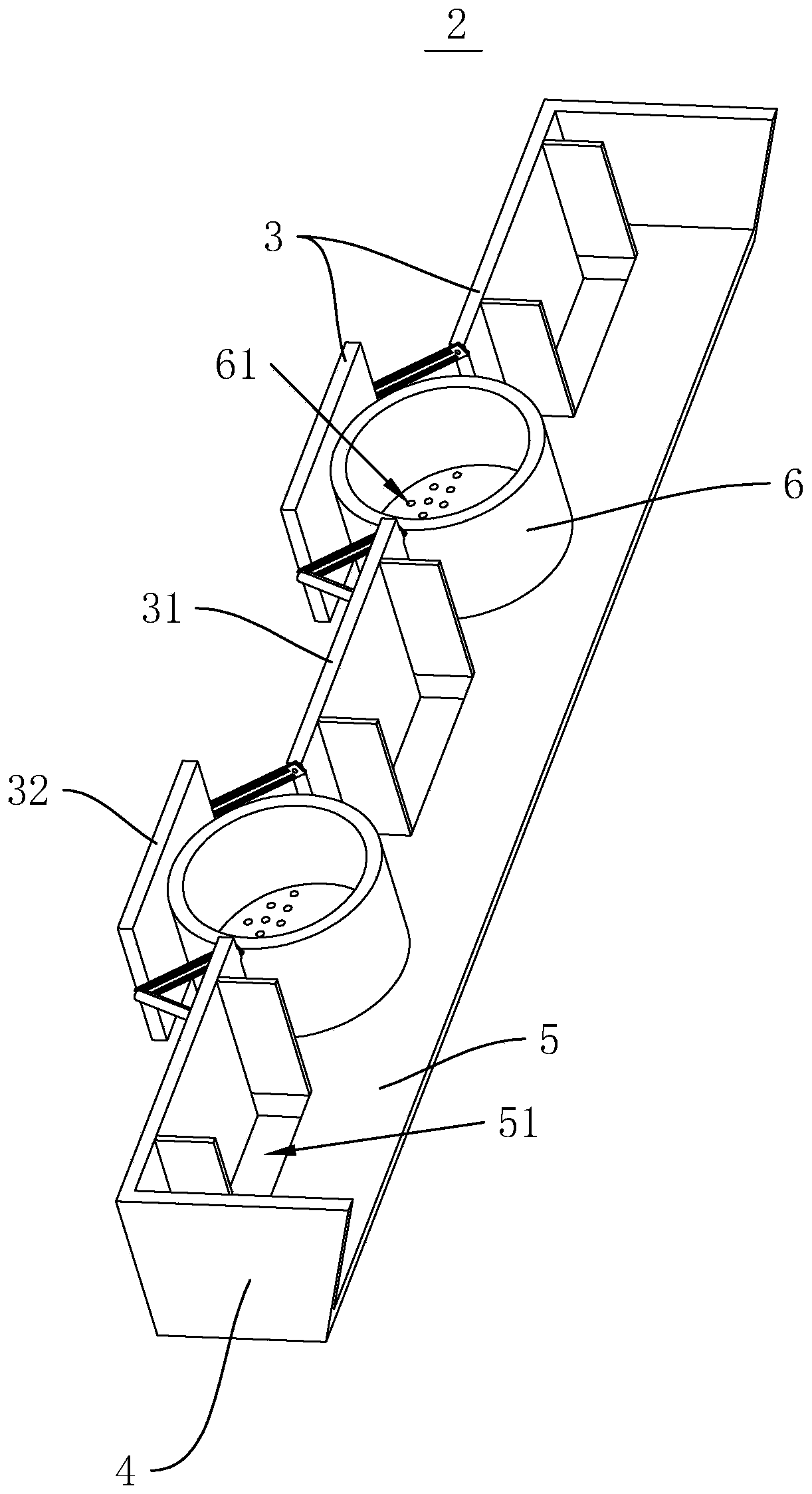

The invention discloses a wooden frame, relates to the technical field of wooden products, and solves the problem that the wooden frame cannot adapt to placement of flowerpots with large sizes. The wooden frame comprises a supporting frame and a plurality of planting grooves, wherein the supporting frame comprises a base and a rear baffle arranged on the base; the planting grooves are formed in the rear baffle in an up-and-down spaced mode, the planting grooves are all formed in an outward inclined mode, each planting groove comprises a bottom plate at the bottom, a front baffle and a side baffle, the front baffles and the side baffles are perpendicularly arranged on the bottom plates, and the bottom plates and the side baffles are connected with the rear baffles; each front baffle comprises a fixed plate fixedly connected with the corresponding bottom plate and an adjusting plate connected with the corresponding fixed plate, the fixed plates and the adjusting plates are arranged in astaggered mode, and adjusting assemblies for controlling the adjusting plates to starch outwards are arranged at the joints of the fixed plates of the adjusting plates. Flowerpots with the diameters of slightly larger than the widths of the planting grooves can be placed.

Description

Technical field [0001] The invention relates to the technical field of wooden products, in particular to a wooden frame and its production process. Background technique [0002] Existing attached Figure 7 The wooden frame shown in, which is used as a planting frame for setting flower pots, includes a support frame 1 and a number of planting troughs 2 arranged on the support frame 1, and a flower pot is placed in the planting trough 2 to plant green plants, wherein the planting trough 2 It is inclined outwards to facilitate viewing of the green plants. [0003] After the flower pot is placed on the wooden frame, the planting groove can cover the flower pot to realize the concealment of the flower pot. The green plants planted in the flower pot can extend out of the planting groove for viewing, thereby enhancing the viewing effect. [0004] However, due to the fixed structure of the wooden frame, only fixed-size flowerpots or smaller flowerpots can be placed, which cannot be adapted t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A01G9/02A47G7/04B27M1/08B27M3/00

CPCA01G9/023A47G7/041B27M1/08B27M3/0073

Inventor 周则雨莫余安陶学富

Owner 福州希达木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com