Sensor Fault Diagnosis Method of Aeroengine Control System Based on AANN Network Group

A technology for aero-engine and sensor failures, applied in general control systems, control/adjustment systems, test/monitoring control systems, etc., can solve problems such as difficult to adapt to engine work uncertainties and complex working conditions, misjudgments, missed judgments, etc. , to achieve the effect of improving the fault detection rate, improving the rapidity, and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

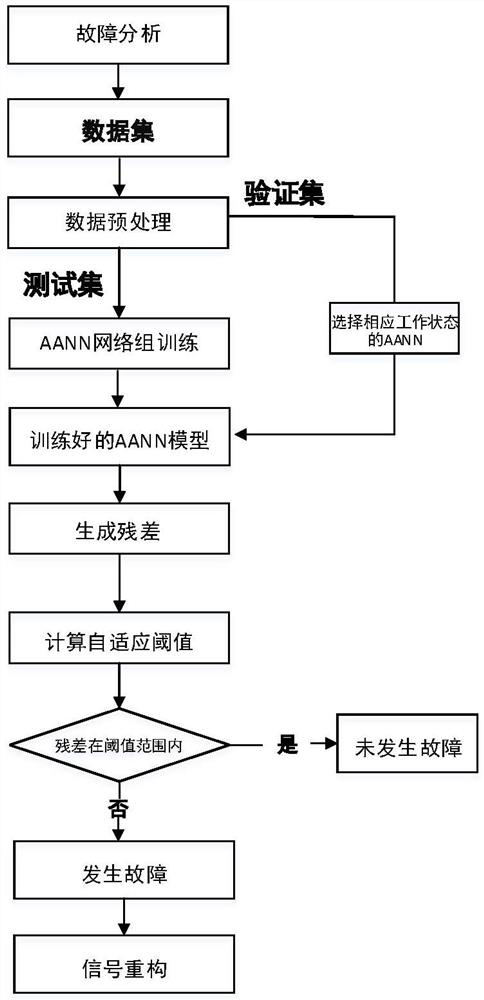

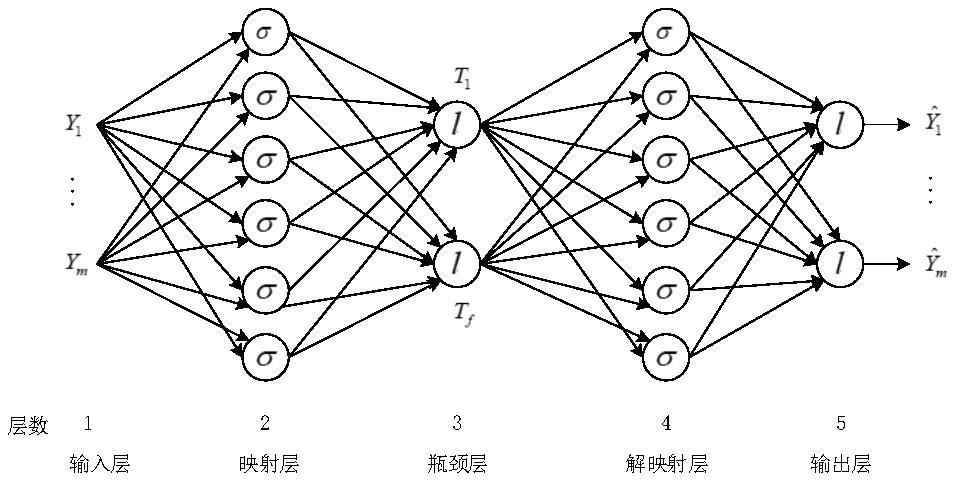

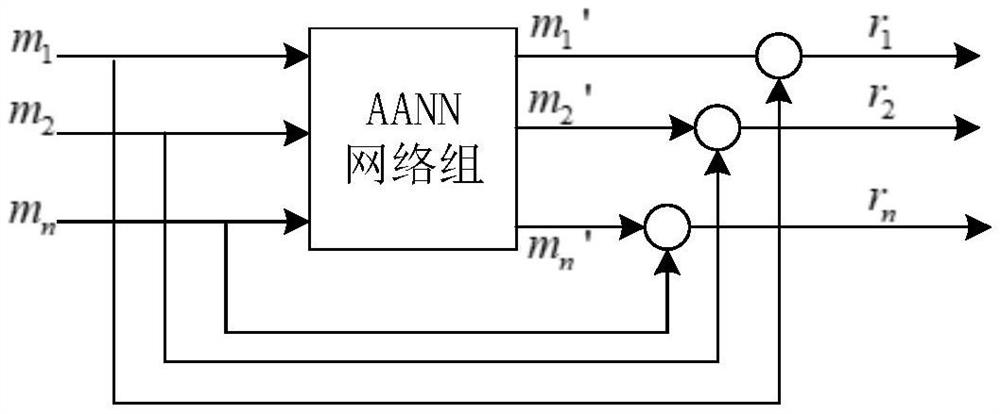

[0061] It is difficult to establish a mathematical model for aero-engine control systems, and the effect of fault diagnosis is often restricted by the accuracy of the model; and the current fault diagnosis technology for sensors can complete fault diagnosis and isolation, but it needs to be carried out in two or more steps. There is also less research on signal reconstruction; according to the requirements of rapid diagnosis, the diagnosis system needs to be able to detect, isolate and restore faults at the same time. Moreover, the aero-engine sensors work under severe working conditions, and there are many interferences, and the basic AANN network is difficult to adapt to the uncertainty and changeable working conditions of the engine. Therefore, in order to solve the above problems, improve the accuracy of sensor fault diagnosis, efficiently and accurately identify the failure mode of complex nonlinear aero-engine systems, realize the synchronization of sensor fault detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com