AOI character defect detection method and device based on industrial machine vision

A character and defect technology, which is applied in the field of AOI character defect detection based on industrial machine vision, can solve problems such as low recognition accuracy, limited photo quality requirements, and reduced product qualification rate, achieving the effect of accurate matching results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Based on the aforementioned inventive concept, this embodiment is a method for detecting AOI character defects, including:

[0079] Obtain the image to be detected;

[0080] Perform preprocessing on the image to be detected to obtain a region-of-interest image with corrected positions and characters;

[0081] Separating the image of the region of interest of the image to be detected to obtain the image of the character region;

[0082] Perform template matching on the character area image of the image to be detected and the pre-created reference image template to obtain the template matching result;

[0083] Judging whether there is a character defect in the image to be detected according to the template matching result;

[0084] The character defect judgment result is output.

[0085] In the method of the present invention, the pre-created reference image template is trained by using a plurality of character image samples containing characters to be detected, and th...

Embodiment 1-1

[0087] Based on Embodiment 1, this embodiment specifically introduces an AOI character defect detection method based on industrial machine vision.

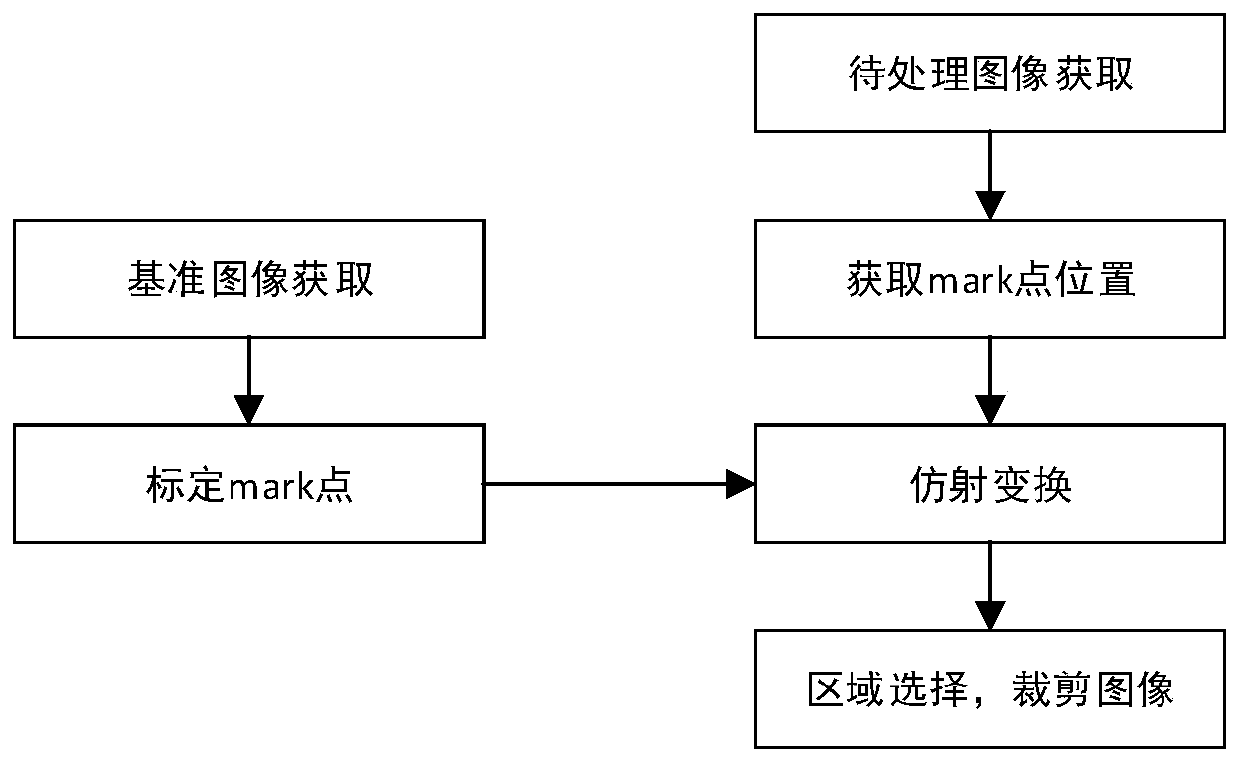

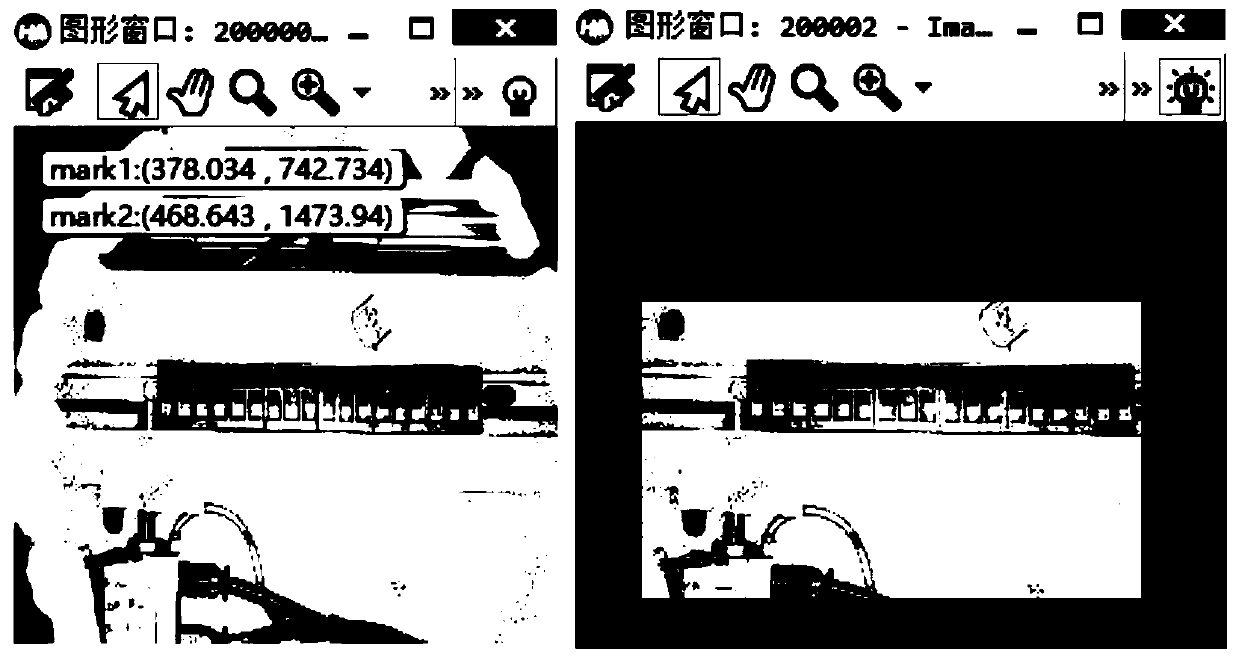

[0088] The template matching of the present invention is based on the establishment of the reference image template and the position correction of the image to be detected and the selection of the character area. figure 1 As shown, before the actual detection is implemented, it is necessary to determine and acquire the reference image first, and determine the calibration points and mark points of the reference image. When detection is required, it is necessary to obtain the image to be detected first, pass its mark point, and then perform an affine transformation to make the image to be detected coincide with the mark point of the reference image to achieve position correction, and then crop the rectangular image area containing characters, such as figure 2 shown.

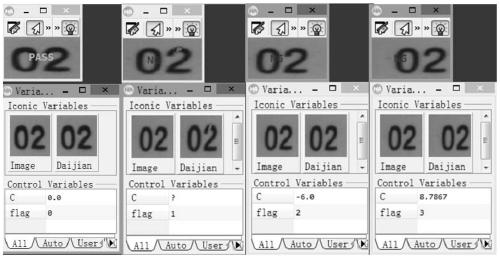

[0089] refer to Figure 4 As shown, in this embodiment, the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com