A quick release hinge

A quick-release, hinged technology, used in construction, door/window fittings, folding panels, etc., can solve problems such as difficult disassembly and inability to hinge, and achieve the effect of convenient cleaning, reducing friction, and avoiding excessive gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

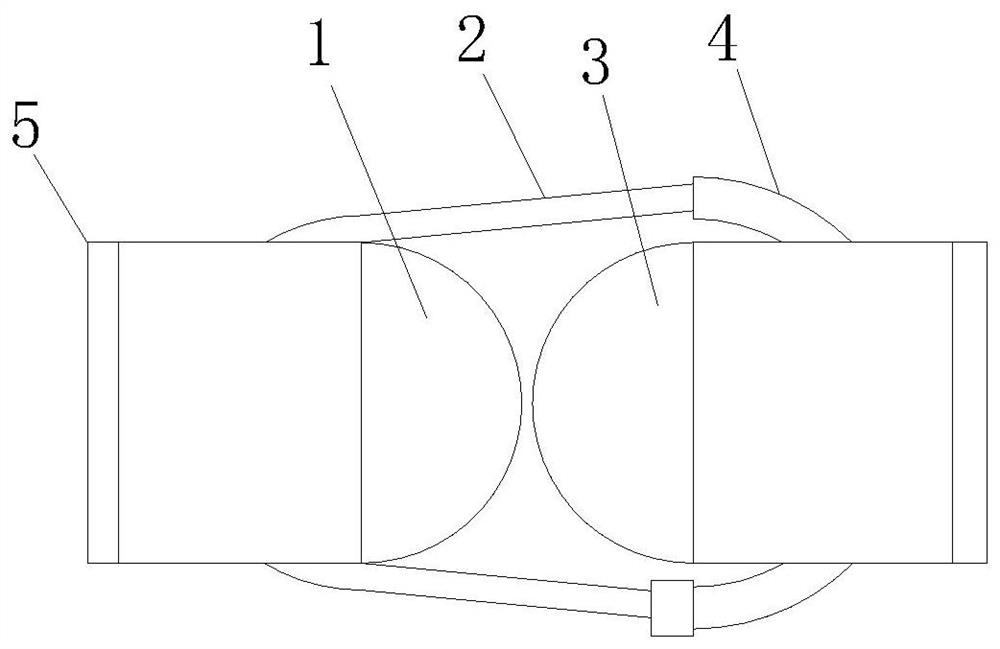

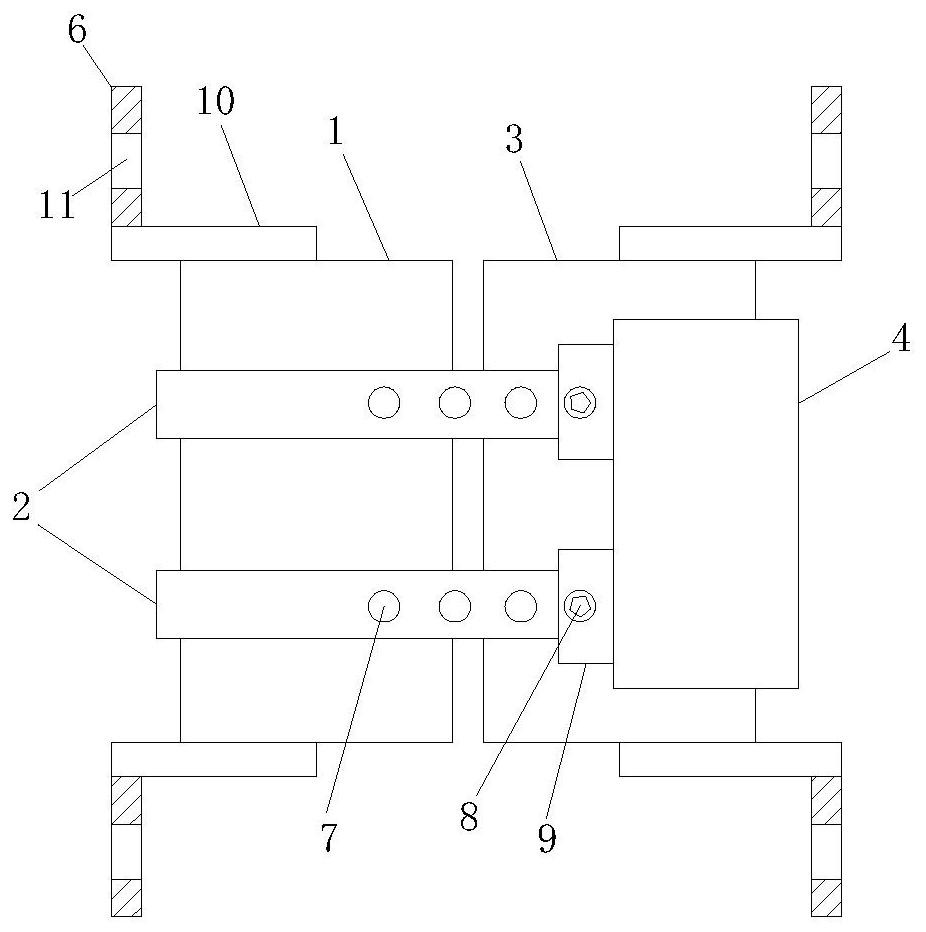

[0029] see Figure 1-3 , a quick-release hinge, including a first cylinder 1, a second cylinder 3 is provided on the right side of the first cylinder 1, and the first cylinder 1 and the second cylinder 3 are installed on the upper and lower sides respectively There is a fixing mechanism 5, and the fixing mechanism 5 includes a connecting rod 10 connected to the first cylinder 1 and the second cylinder 3, a fixing plate 6 is installed on the connecting rod 10, and a fixing hole 11 is provided on the fixing plate 6, so that On the right side of the second cylinder 3, a fixed ring 4 is installed, and a limit brace 2 is installed on the fix ring 4. The limit brace 2 and the fix ring 4 are designed to wrap the first cylinder 1 and the second cylinder 3;

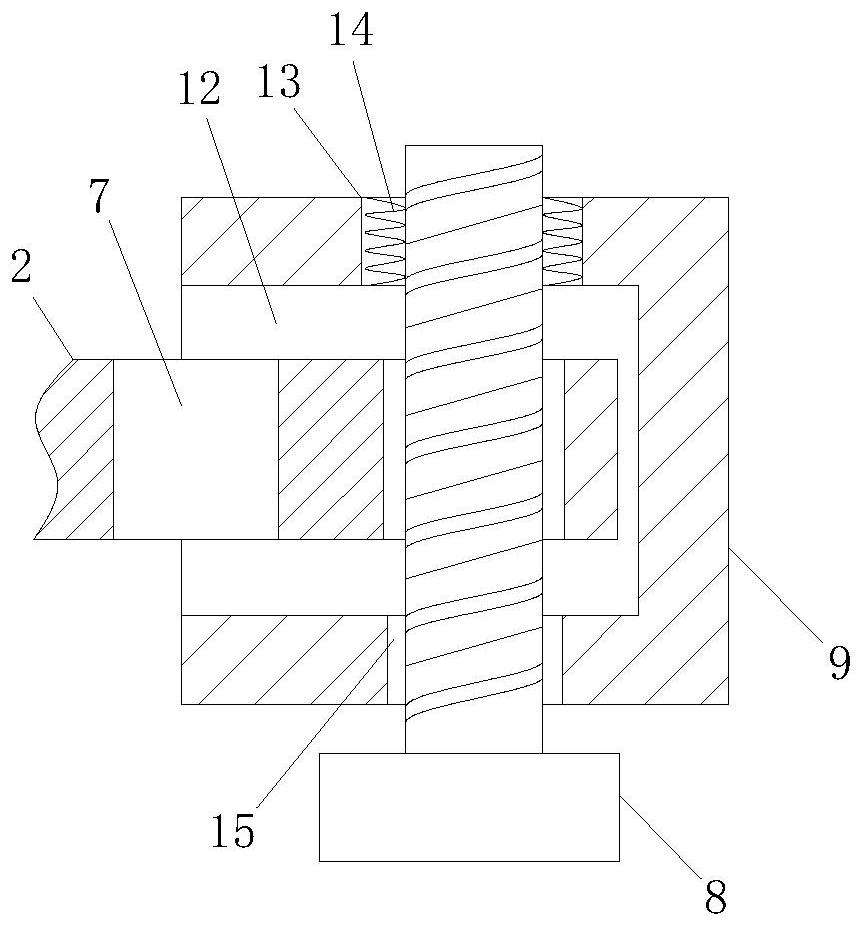

[0030] One end of the limit stay bar 2 is movably connected with the fixed ring 4 through a connector 9, and a through hole 7 is uniformly arranged on the limit stay bar 2, and a corresponding position of the limit stay bar 2 is p...

Embodiment 2

[0033] see Figure 1-4 , a quick-release hinge, including a first cylinder 1, a second cylinder 3 is provided on the right side of the first cylinder 1, and the first cylinder 1 and the second cylinder 3 are installed on the upper and lower sides respectively There is a fixing mechanism 5, and the fixing mechanism 5 includes a connecting rod 10 connected to the first cylinder 1 and the second cylinder 3, a fixing plate 6 is installed on the connecting rod 10, and a fixing hole 11 is provided on the fixing plate 6, so that On the right side of the second cylinder 3, a fixed ring 4 is installed, and a limit brace 2 is installed on the fix ring 4. The limit brace 2 and the fix ring 4 are designed to wrap the first cylinder 1 and the second cylinder 3;

[0034] One end of the limit stay bar 2 is movably connected with the fixed ring 4 through a connector 9, and a through hole 7 is uniformly arranged on the limit stay bar 2, and a corresponding position of the limit stay bar 2 is p...

Embodiment 3

[0037] see Figure 1-5 , a quick-release hinge, including a first cylinder 1, a second cylinder 3 is provided on the right side of the first cylinder 1, and the first cylinder 1 and the second cylinder 3 are installed on the upper and lower sides respectively There is a fixing mechanism 5, and the fixing mechanism 5 includes a connecting rod 10 connected to the first cylinder 1 and the second cylinder 3, a fixing plate 6 is installed on the connecting rod 10, and a fixing hole 11 is provided on the fixing plate 6, so that On the right side of the second cylinder 3, a fixed ring 4 is installed, and a limit brace 2 is installed on the fix ring 4. The limit brace 2 and the fix ring 4 are designed to wrap the first cylinder 1 and the second cylinder 3;

[0038]One end of the limit stay bar 2 is movably connected with the fixed ring 4 through a connector 9, and a through hole 7 is uniformly arranged on the limit stay bar 2, and a corresponding position of the limit stay bar 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com