Coal mine robot rail system and its omnidirectional deformation connection structure

A connecting structure and robot technology, applied in the track field, can solve the problems of heavy workload, difficulty in repairing and maintaining curved track, etc., and achieve the effect of smooth and smooth walking track.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

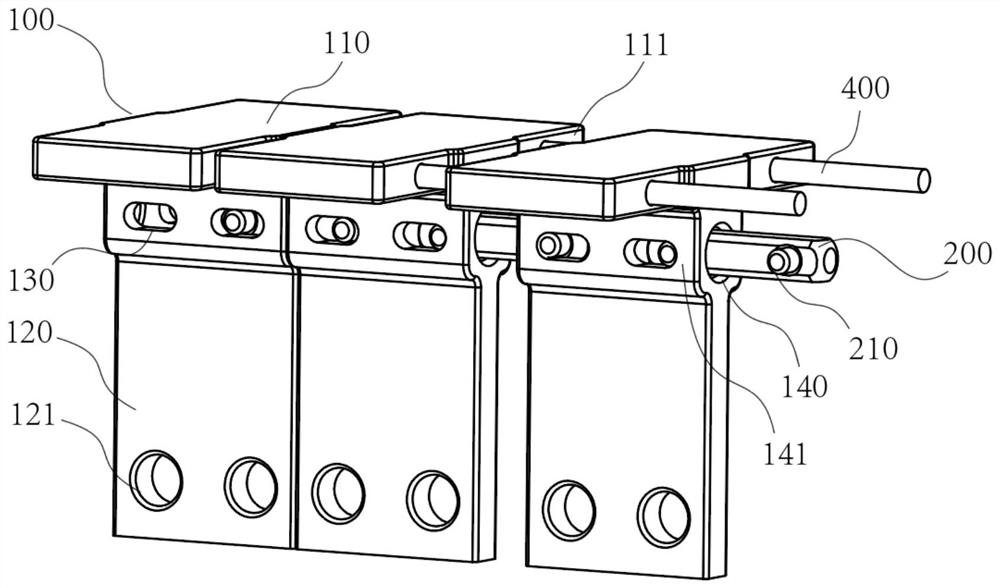

[0027] Such as figure 1 Shown is an implementation of a connection structure of the present invention, the connection between the support part 120 of the module unit 100 and the running part 110 is provided with a receiving hole 140 along the direction of the track, the connection member 200 is columnar, and its two ends are set In the receiving hole 140, the long hole 130 is arranged on the side walls on both sides of the receiving hole, and the limiting part 130 is a plug pin or a columnar part such as an expansion pin, and the connecting member 100 is vertically inserted into the long hole 130 on one side. The end of the connecting member 100 is extended into the long hole on the other side, and the end of the connecting member 100 is restricted in the receiving hole 140 .

[0028] In the embodiment of the present invention, the cross-sectional diameter of the limiting part 210 is slightly smaller than the width of the elongated hole 130, and at the same time, the maximum d...

Embodiment 2

[0035] Such as figure 2 The difference between the implementation of another connection structure of the present invention shown in Embodiment 1 is that the lower end of the support part 120 of the module unit is also provided with a second receiving hole 142, and the second receiving hole 142 of two adjacent module units A second connection member 201 is provided between the holes.

Embodiment 3

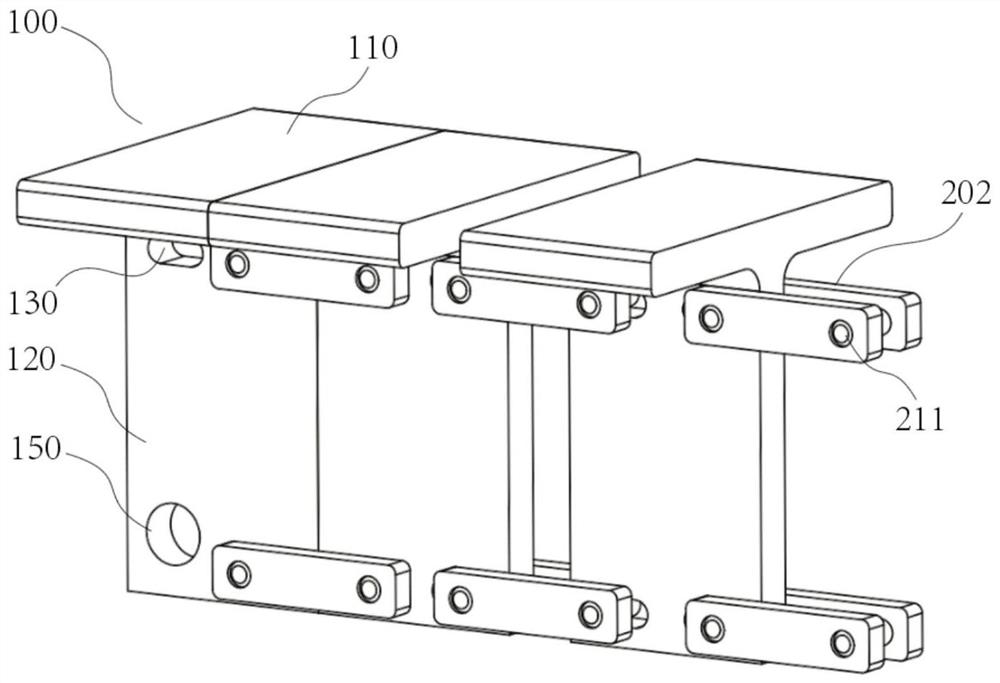

[0037] Such as image 3 The realization of another connecting structure of the present invention is shown, the connecting members shown are connecting pieces 202 arranged in pairs on both sides of two adjacent module units, and the ends of the connecting members 202 are placed on both sides of the elongated holes 130. On the side, the limiting part 211 connects the connecting members 202 on both sides through the long hole, so that a pair of connecting members are clamped on both sides of the module unit 100 .

[0038] In the embodiment of the present invention, the distance between the pair of connection members 202 is greater than the thickness of the module unit 100, so that there is a gap between the connection members and the module unit.

[0039] Preferably, the connecting members 202 are in two groups, which are respectively arranged at the upper and lower ends of the support part of the modular unit.

[0040] Preferably, series ribs are also provided between the runni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com