Cyclic recycling equipment for carrier

A technology of recycling and equipment, applied in the direction of mechanical conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of frequent steps, increased use costs, increased costs, etc., to achieve stable operation, improve space utilization, and save labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is further elaborated below by specific embodiment:

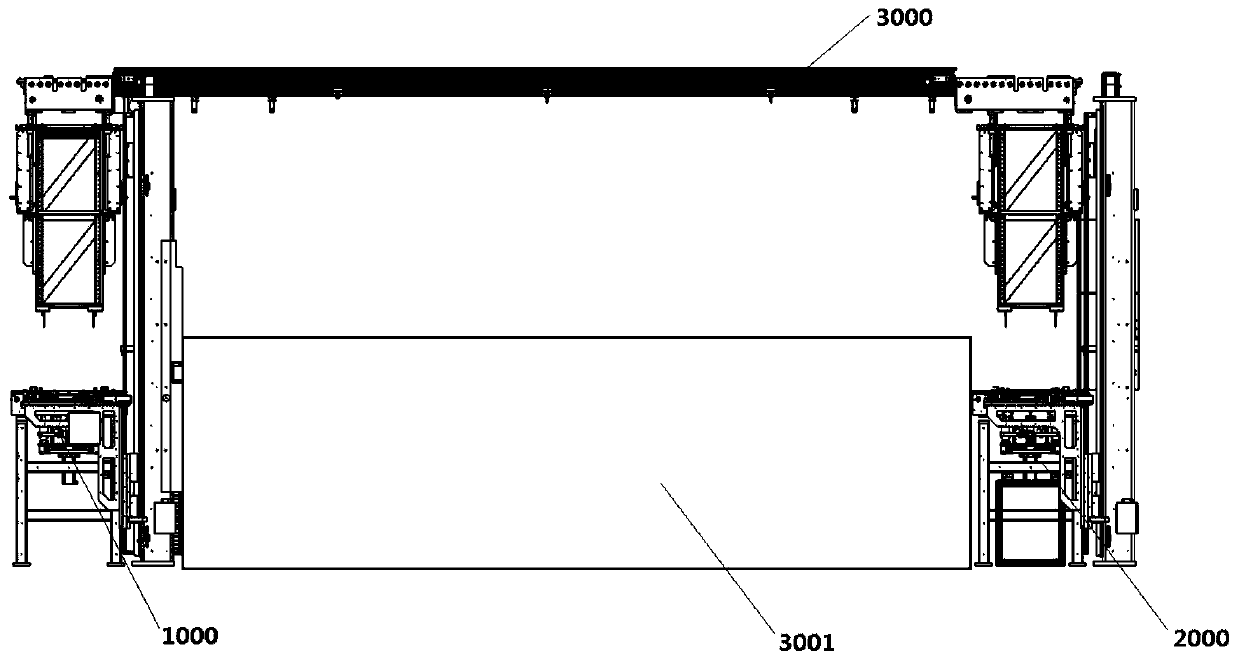

[0040] Such as figure 1 As shown, a carrier recycling equipment includes a feeding mechanism 1000 , a feeding mechanism 2000 and a return conveyor belt 3000 .

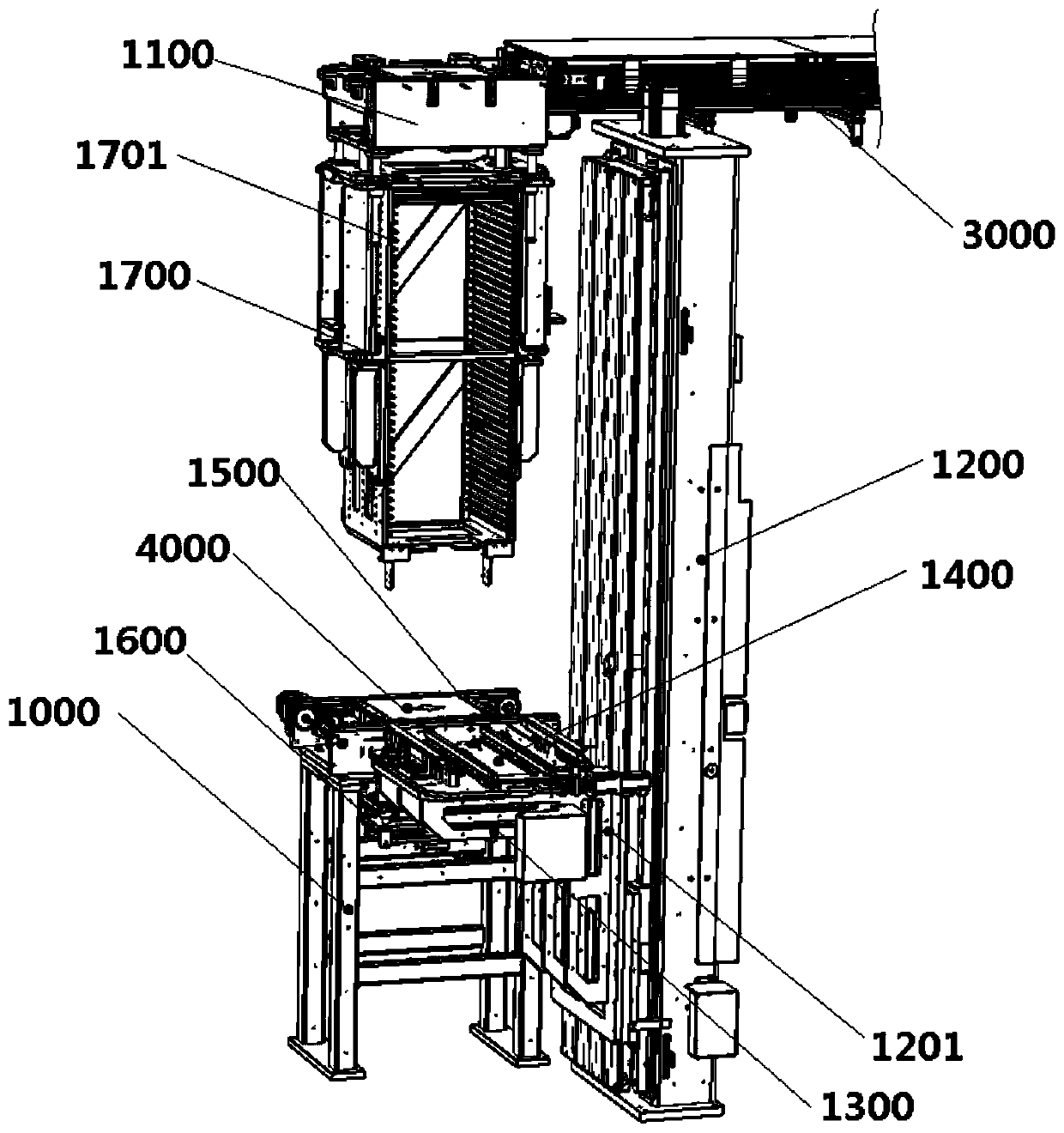

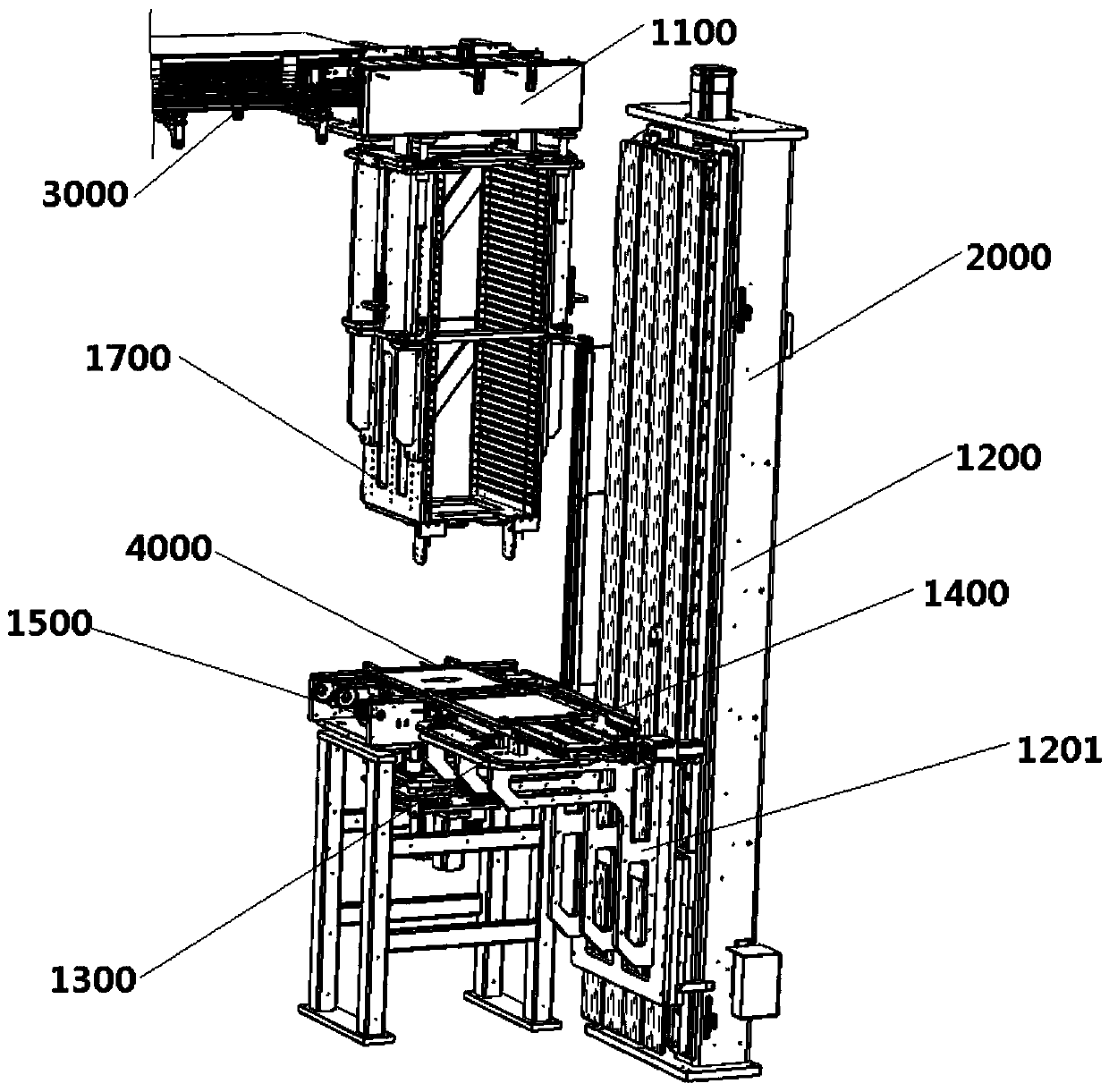

[0041] Such as figure 2 and image 3 As shown, the loading mechanism 1000 and the unloading mechanism 2000 have the same structure, and they both include a roller belt 1100 , a lifting guide rail 1200 , a lifting platform 1300 , a pick-and-place mechanism 1400 , a conveying platform 1500 and a jacking mechanism 1600 .

[0042] Wherein, the roller belt 1100 is located directly above the conveying platform 1500 , the lifting guide rail 1200 is located on one side of the roller belt 1100 and the conveying platform 1500 , and the lifting platform 1300 is connected with the lifting guide rail 1200 through a slider 1201 . The pick-and-place mechanism 1400 is located on the lifting platform 1300 , and the jacking mechanism 1600 is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com