Control method and device for preventing sudden change of gas volume in dishwasher inner cavity

A gas volume and control method technology, which is applied to automatic detection, cleaning devices, household cleaning devices, etc. under the control of dishwashing machines/rinsing machines, can solve problems such as scalding when opening the lid, to avoid hot air hitting the lid, prevent damage, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

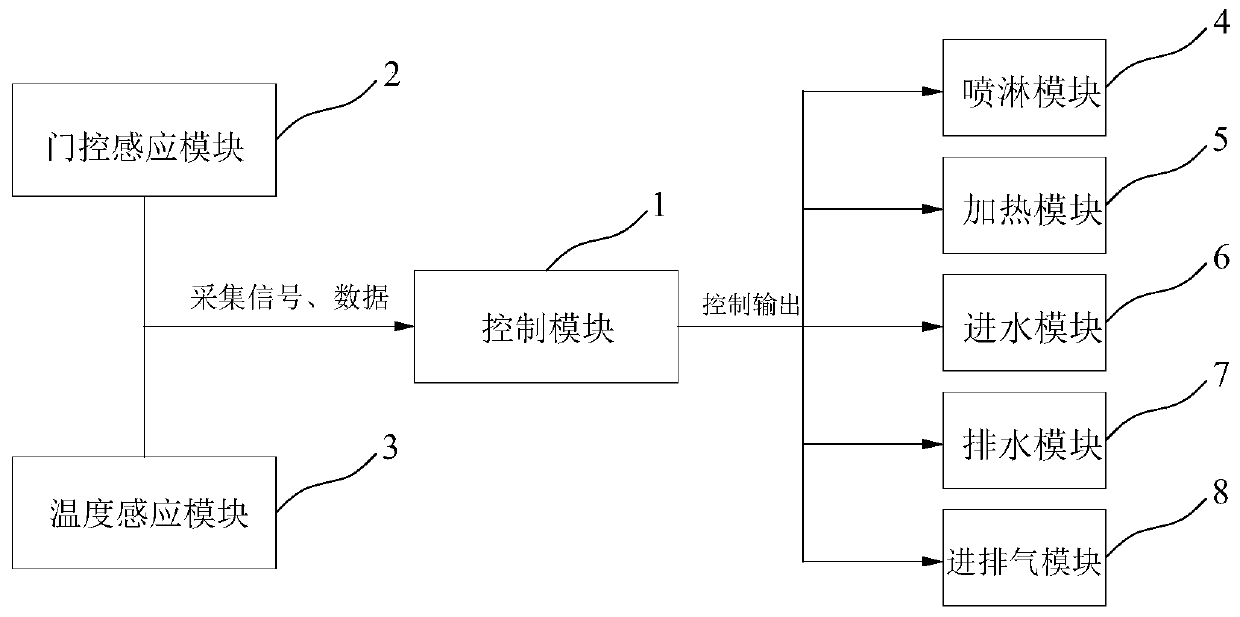

[0031] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

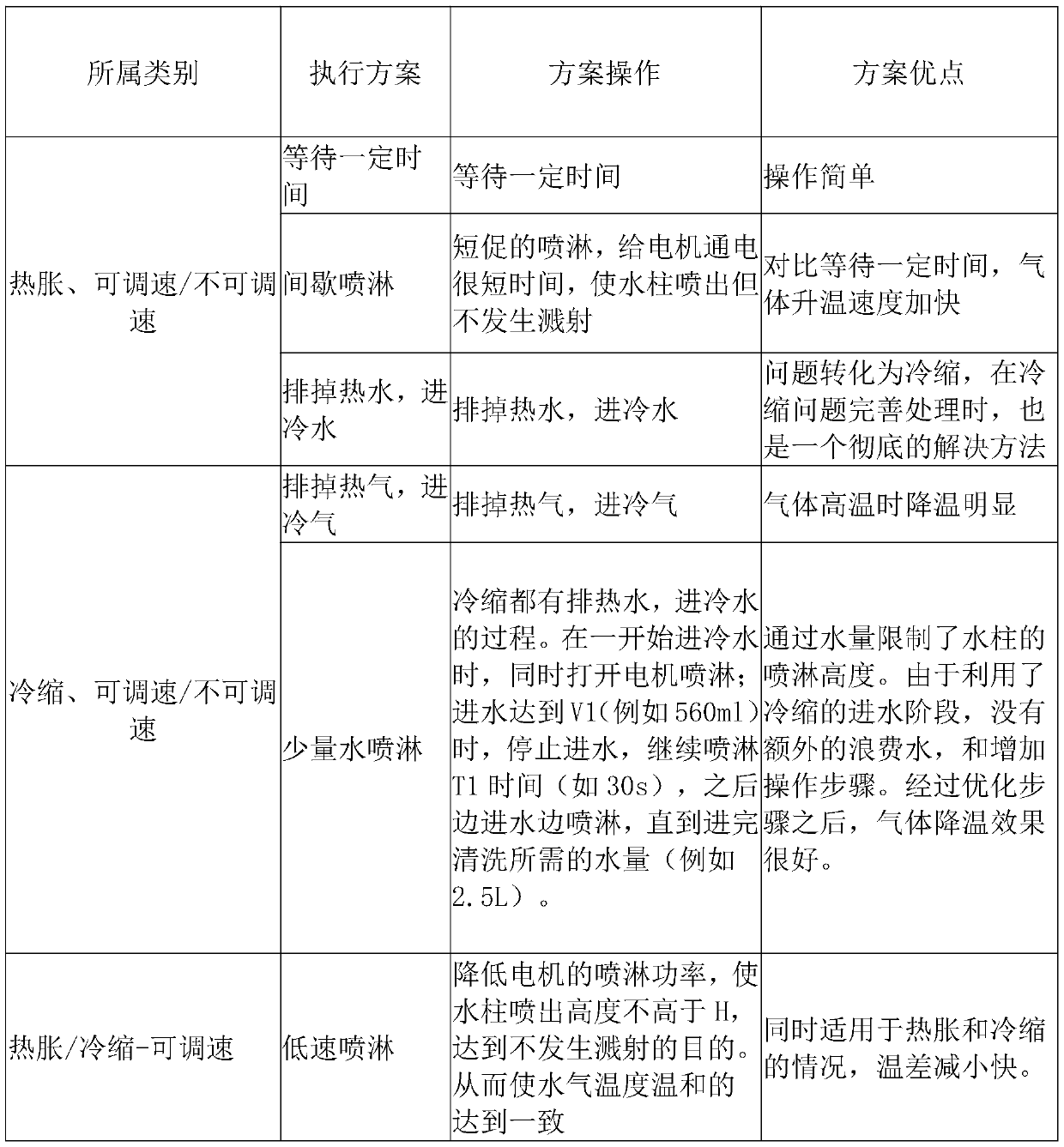

[0032] Referring to Table 1 below, the present invention discloses a control method and control device for preventing sudden changes in the gas volume of the dishwasher cavity, which includes the following steps:

[0033] S1. Detection event: Collect the dishwasher’s lid opening signal, water inlet signal, drainage signal, and water temperature and air temperature data in the inner cavity, and judge whether thermal expansion / cold contraction occurs according to the lid opening signal, water inlet signal, and drainage signal , if thermal expansion / cold c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com