Buried compression-resistant cable

A buried, cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor core protection effect and unreasonable cables, so as to improve the overall shear resistance and compression resistance, and increase buffering. effect, effect of increasing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

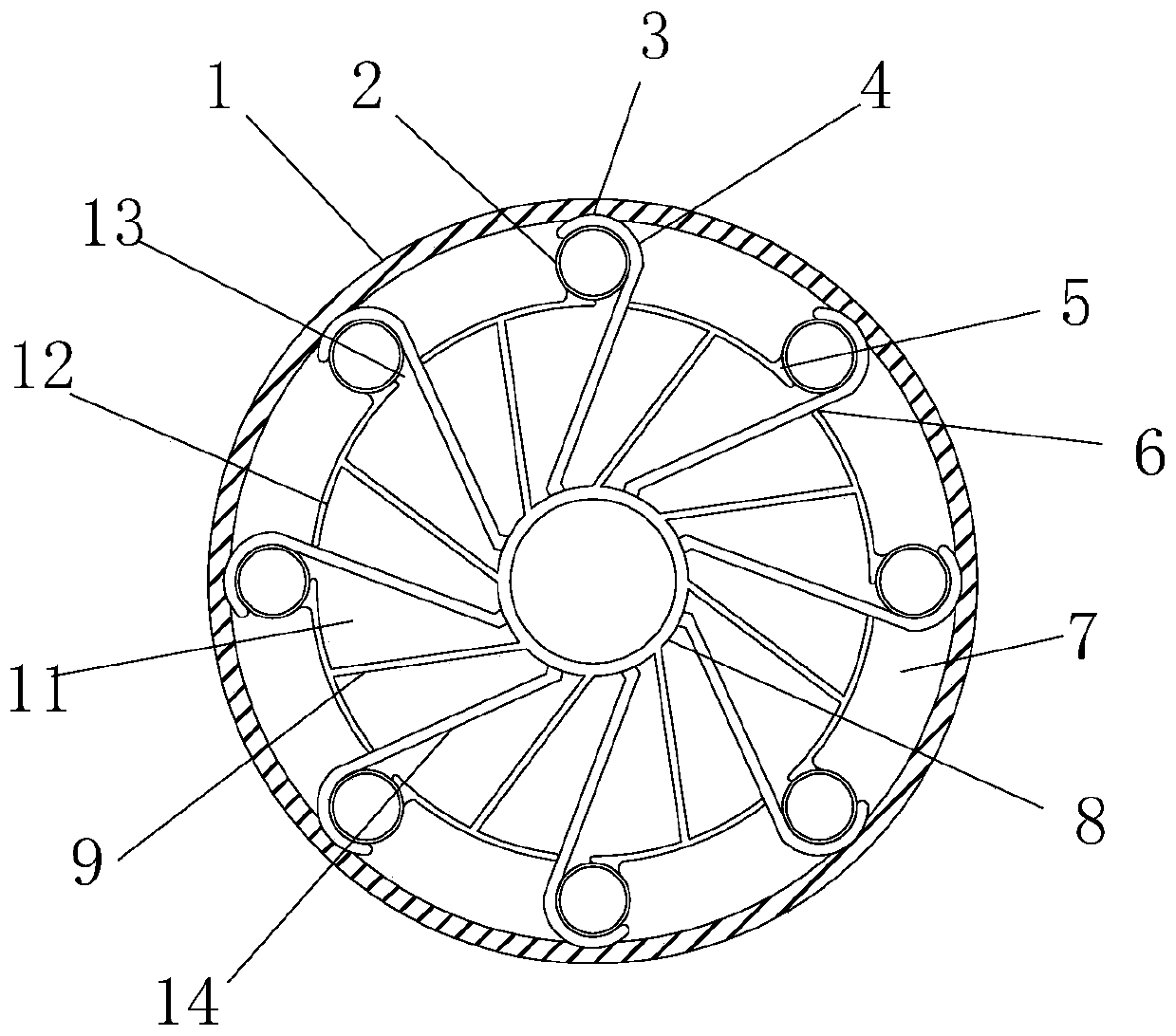

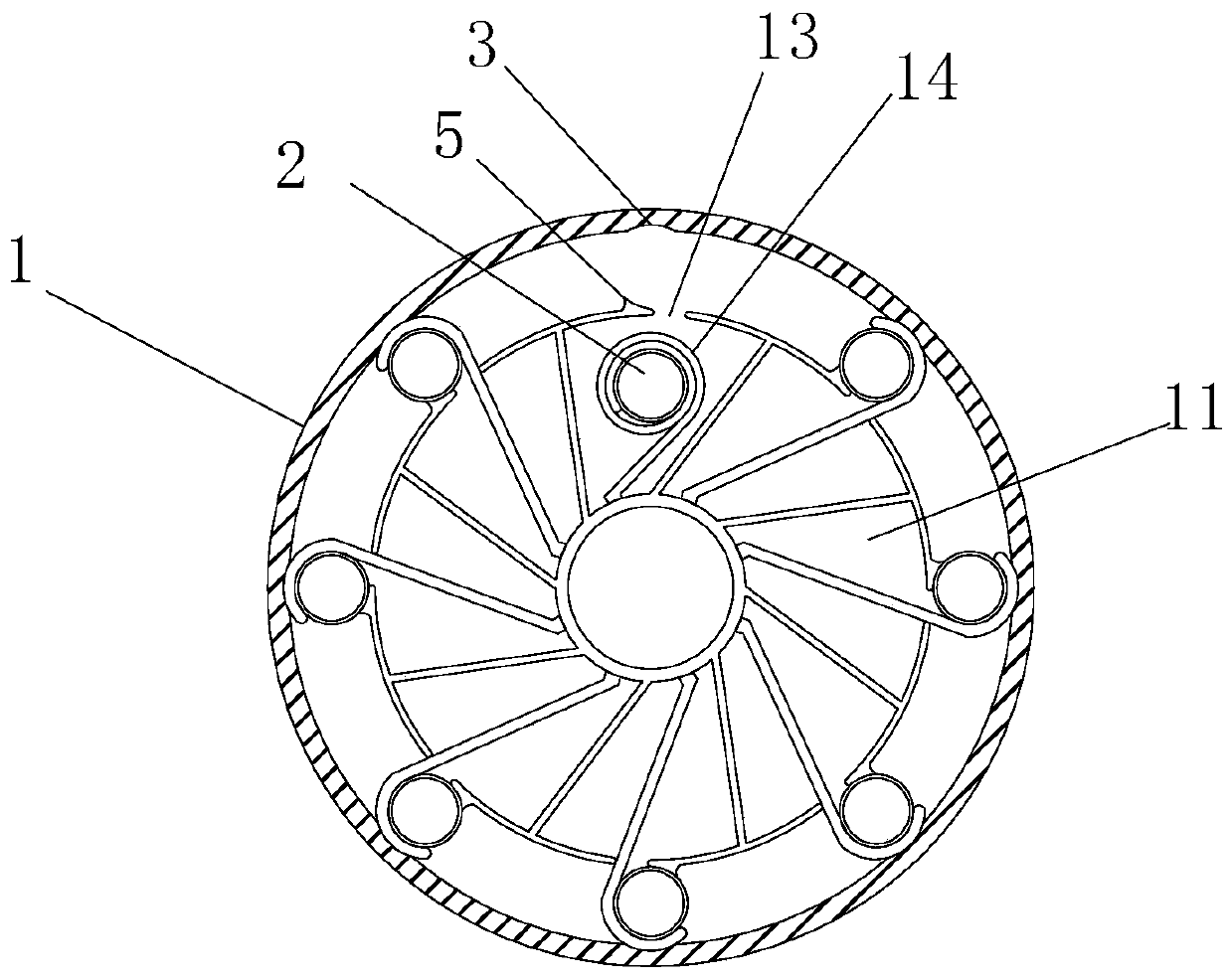

[0015] Such as figure 1 As shown, the local buried pressure-resistant cable includes a cable outer protective layer 1, an installation cavity is formed in the cable outer protective layer 1, and an elastic support cage 12 is installed in the installation cavity, and the elastic support cage 12 is along the length of the cable outer protective layer 1. direction, a gap cavity 7 is formed between the outer wall surface of the elastic support cage 12 and the inner wall surface of the installation cavity, and more than one cable core wire 2 is arranged in the gap cavity 7, and an elastic support part 14 is elastically stretched out of the elastic support cage 12 , the elastic supporting part 14 protrudes from one end of the elastic supporting cage 12 to form an arc-shaped wrapping part 4, the arc-shaped wrapping part 4 wraps part of the cable core wire 2, and the cable core wire 2 is directed toward the elastic supporting cage 12 through the elastic supporting part 14 Press tight....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com