Multi-material rapid comparison and matching method for production line

A matching method and multi-material technology, applied in the field of material matching of production lines, can solve the problems of low recognition accuracy and achieve the effects of good adaptability, good stability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

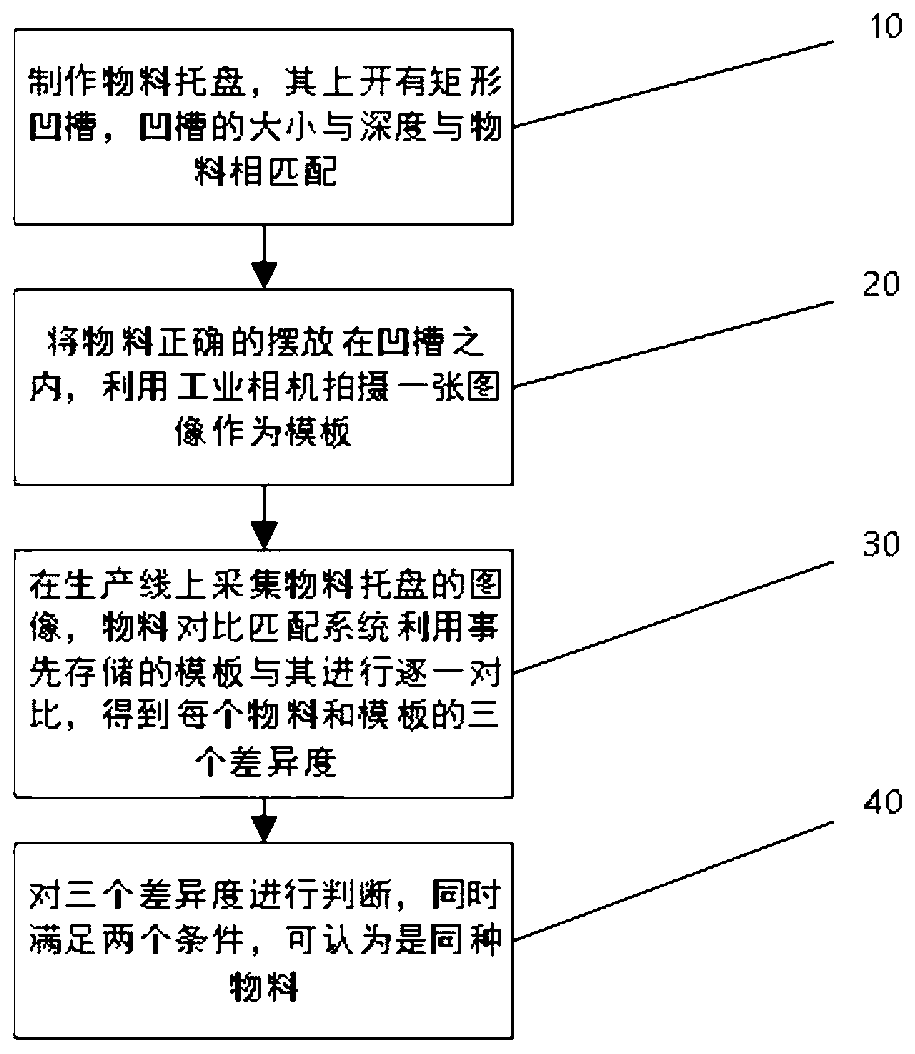

[0041] A multi-material rapid comparison and matching method for a production line is characterized in that it specifically includes the following steps:

[0042] Step 1. Determine the type, quantity and placement of the materials placed on each material pallet;

[0043] Step 2. Make a variety of material trays, each tray contains some rectangular grooves, and the size and depth of the grooves match the materials;

[0044] Step 3. Place various types of materials correctly in the rectangular groove of the pallet, and take an image of the entire pallet with an industrial camera installed above the pallet as a template; each material pallet has a template;

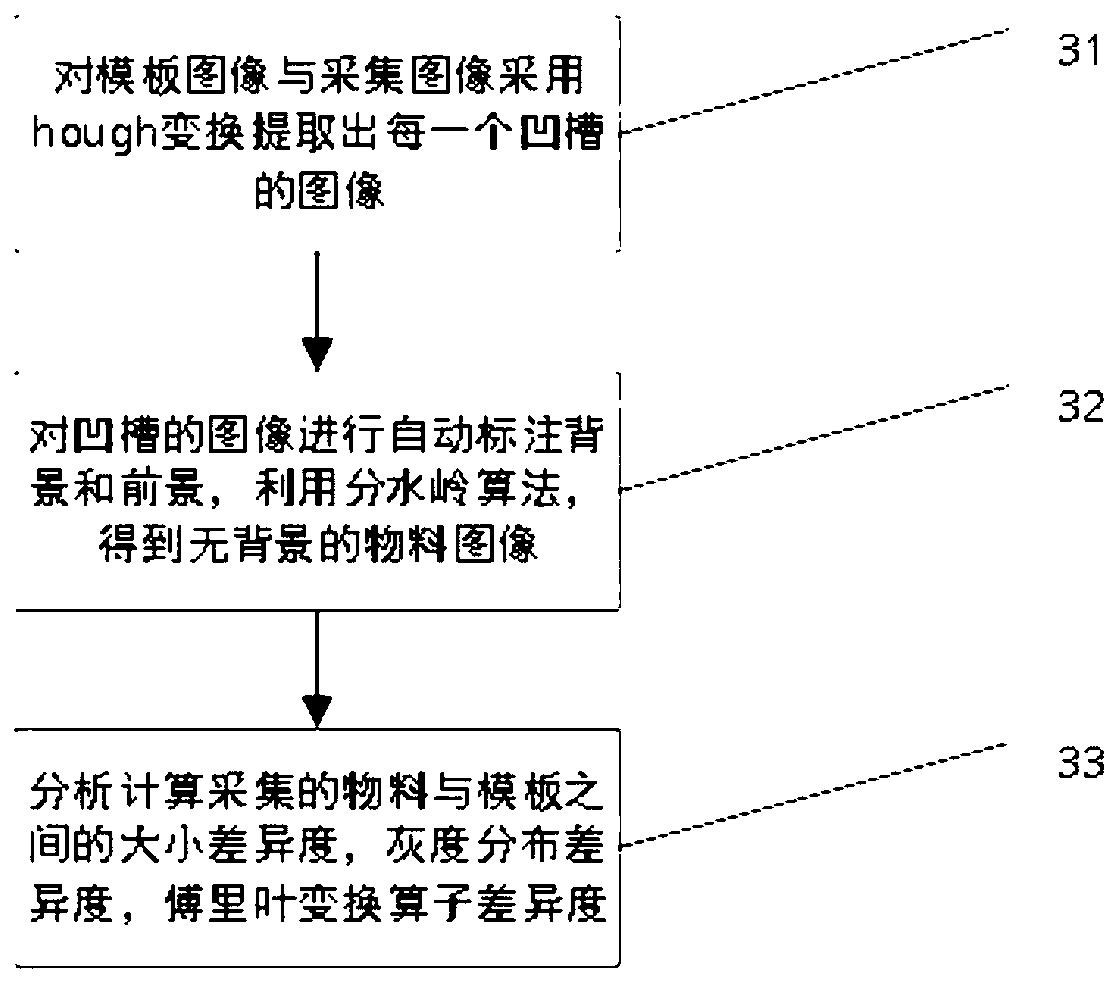

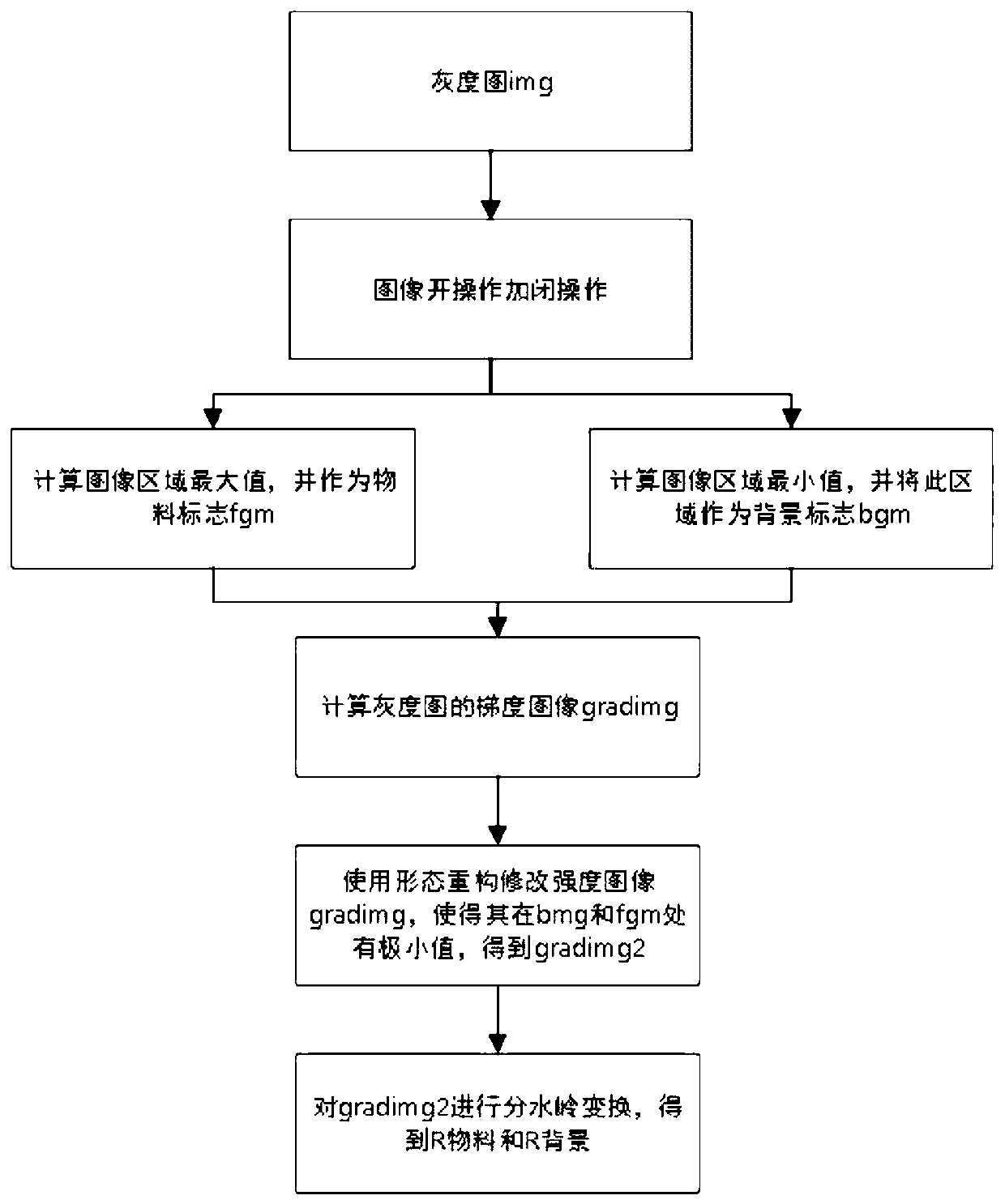

[0045] Step 4. On the production line, the material comparison and matching system collects the image of the material pallet, performs Hough transformation on it to obtain a rectangular groove image, and uses the method of automatically marking the watershed to segment the groove image, extracts the material image, and compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com