Design control method of boiler furnace outlet gas temperature

A technology of flue gas temperature and boiler furnace, which is applied in the field of design and control index of flue gas temperature at the outlet of boiler furnace based on initial slagging temperature, can solve the problems of inability to meet the requirements of boiler slagging, slagging and fouling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

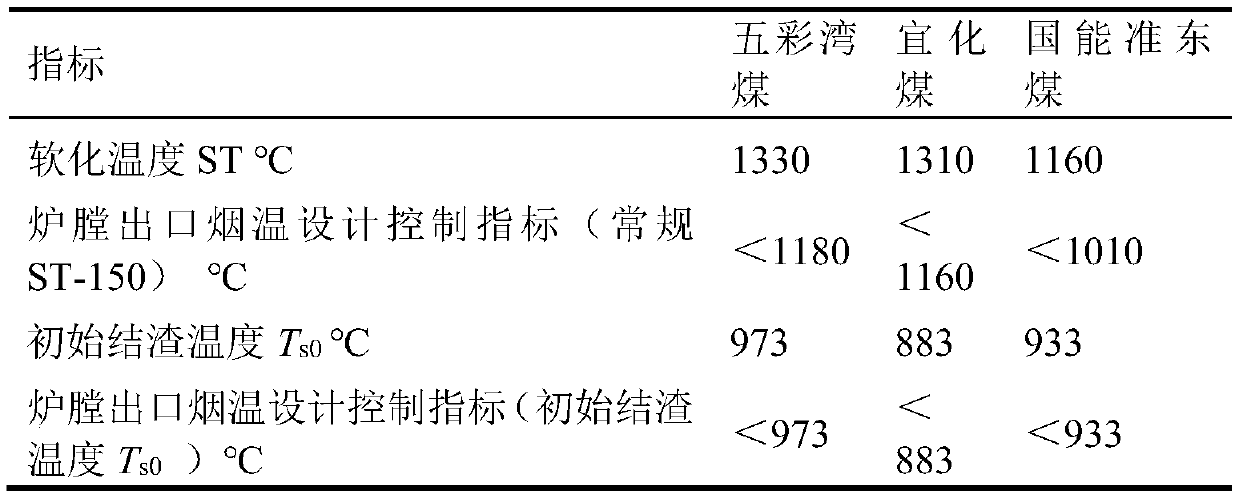

[0033] The present invention has collected Xinjiang high-alkaline coal (Wucaiwan coal, Yihua coal, Guoneng Zhundong coal), and tests the ash composition of the coal sample according to the national standard GB / T1574-2007, according to Ts0=3.57(18-Ki)+1025, Ki=(K 2 O+Na 2 O) 2 +0.048(Fe 2 o 3 +CaO) to calculate the initial slagging temperature Ts0 of different coal samples, which is used as the control index of the flue gas temperature at the furnace outlet of the boiler burning the corresponding coal type, and compared with the conventional control index, as shown in Table 1. It can be seen that the design control index value of the flue gas temperature at the furnace outlet of the boiler fired by the conventional ash melting point ST is higher than that of the initial slagging temperature Ts0 as the design control index value of the flue gas temperature at the furnace outlet. As for the actual situation of slagging, it is obvious that the control method of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com