Pipeline transportation aligning system

A technology for pipes and pipe joints, applied in the field of pipeline transportation counterpart systems, can solve the problems of complicated counterpart operations, cumbersome construction process, long counterpart time, etc., and achieve the effects of improving the harsh field operation environment, wide application range and low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described with reference to the drawings and specific embodiments:

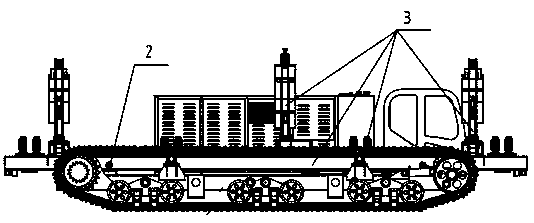

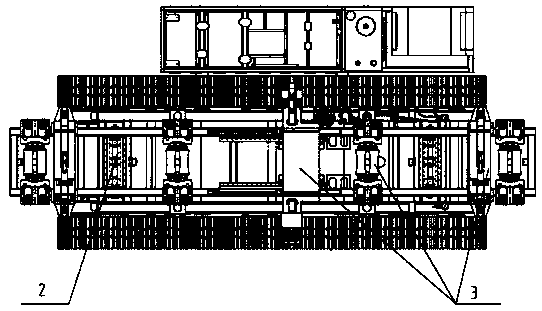

[0071] Such as figure 1 , figure 2 , image 3 As shown, a pipeline transportation engineering vehicle has a vehicle body I1-1, a frame 2 and a pipe section pushing device I3 located on the vehicle frame; the vehicle frame 2 is arranged on the vehicle body I1-1 And it is raised and lowered horizontally relative to the vehicle body I1-1 so that the pipe section pushing device I3 located on the vehicle frame 2 rises and falls with the lifting of the vehicle frame 2; the vehicle frame 2 swings up and down relative to the vehicle body I1-1 to make The pipe section pushing device I3 located on the vehicle frame swings with the swing of the vehicle frame 2. Correspondingly, the pipeline transportation engineering vehicle is provided with a device for horizontally lifting and swinging the vehicle frame relative to the vehicle body I. Frame adjustment devices 2a / 2b; the frame adjustm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap