A kind of preparation system and preparation method of recycled plastic granules

A recycled plastic granule and preparation system technology, applied in the field of recycled plastic granule preparation system and preparation, can solve the problems of poor oil pollution treatment effect, long rinsing journey, omission, etc., and achieve the effect of increasing the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

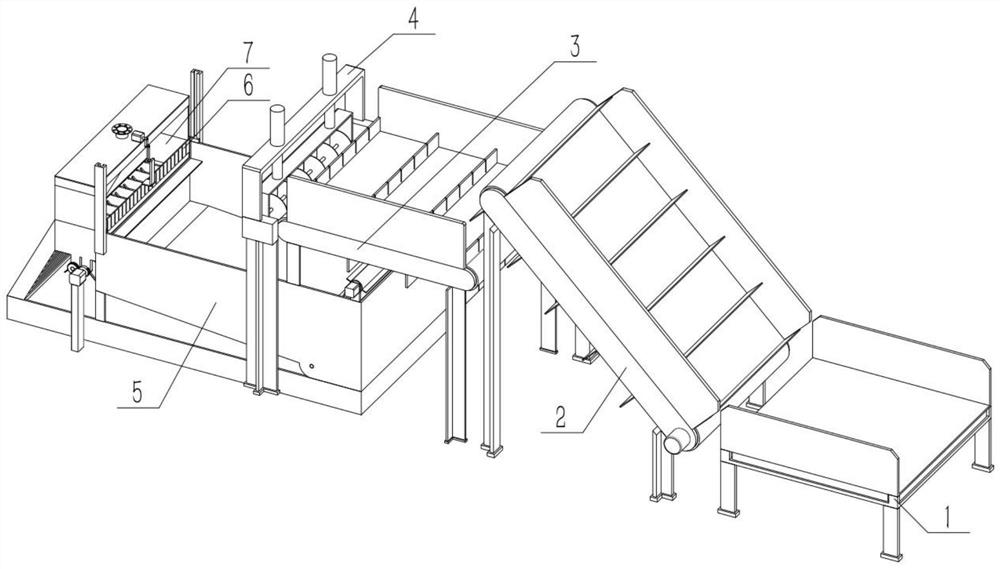

[0035] Such as Figure 1-10 As shown, a recycled plastic particle preparation system includes a belt feeder II3, a fixed frame 4, an electric telescopic rod 401, a moving frame 402, an anti-roll plate 403, a shaft I404 and a blade 405, and the upper end of the fixed frame 4 is installed The electric telescopic rod 401, the movable end of the electric telescopic rod 401 passes through the fixed frame 4, the movable frame 402 is fixedly connected to the movable end of the electric telescopic rod 401, and the two ends of the shaft I 404 are respectively connected to the left and right ends of the lower side of the movable frame 402 , the shaft I404 is driven by the motor I to realize the rotation, and the shaft I404 is uniformly fixed with multiple blades 405 from front to back, and the multiple blades 405 are arranged on the left side of the belt feeder II3; the belt feeder II3 conveys the material to the left until the material After falling, a plurality of blades 405 rotate to...

specific Embodiment approach 2

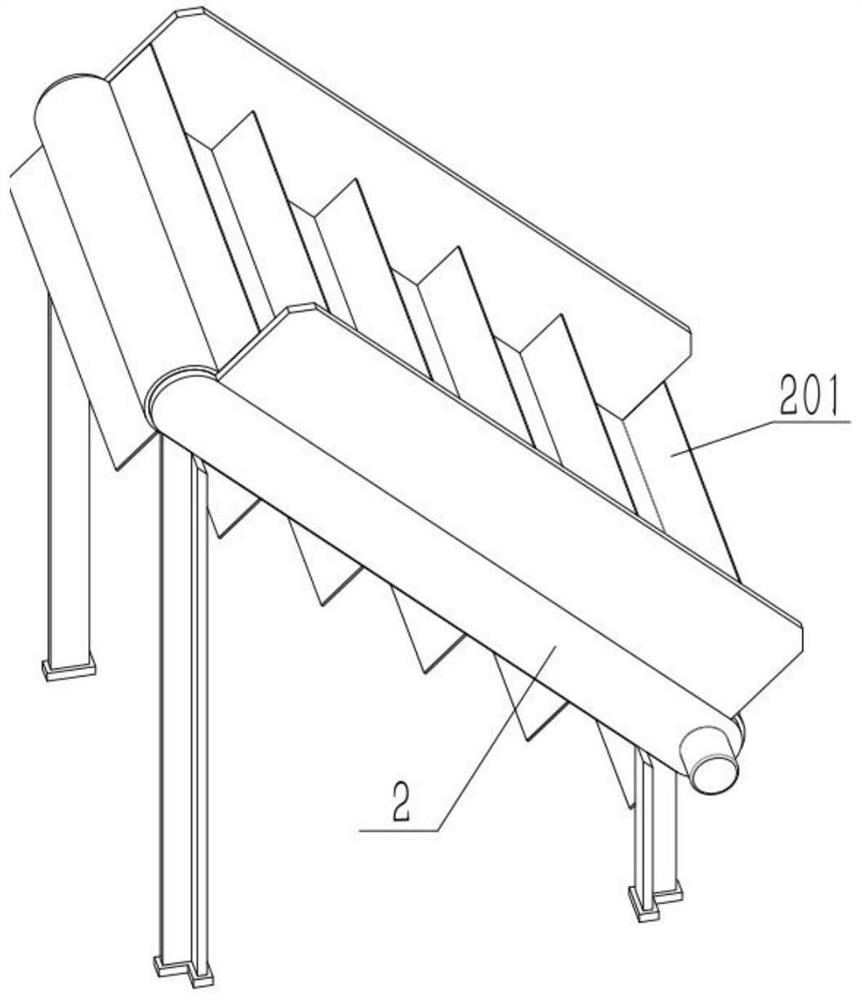

[0036] Such as Figure 1-10As shown, the recycled plastic granule preparation system also includes a distribution box 5, a lower gathering bottom surface 501, an arc surface 502, a roller 503, a conveyor belt 504, a belt plate III 505 and a liquid transfer box 506, and the bottom surface of the distribution box 5 is composed of a lower gathering bottom surface 501 and the arc surface 502 are connected from left to right. The lower bottom surface 501 is higher on the left and lower on the right. There are two rollers 503. One roller 503 is located at the arc surface 502, and the other roller is located at the upper end of the right side of the distribution box 5. Both rollers 503 are rotatably connected to the distribution box 5, and a conveyor belt 504 is installed on the two rollers 503. A plurality of belt plates III 505 are evenly fixed on the conveyor belt 504. The moving belt plate III 505 takes the objects moving to the arc surface 502 out of the distribution box 5; the ...

specific Embodiment approach 3

[0037] Such as Figure 1-10 As shown, the recycled plastic granule preparation system also includes a receiving box 6, a multi-purpose tank 601, a shaft II 602, a dial 603, a gear I 604 and a gear II 605. The two ends of II 602 are respectively connected to the front and rear ends of the lower end of the receiving box 6. There are multiple dials 603, and the dials 603 are wheels with four blades evenly arranged on the circumference. The blades can pass through the multi-purpose groove 601, A plurality of dials 603 are fixedly connected to the shaft II 602, one end of the shaft II 602 is fixedly connected to the gear I 604, the gear I 604 and the gear II 605 are meshed for transmission, the gear II 605 is fixed on the output shaft of the motor III, the motor III drives the gear II 605 to rotate, and the receiving box 6 is affixed to the left end of distribution box 5, and the bottom end surface of receiving box 6 is lower than the left end surface of distribution box 5. The pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com