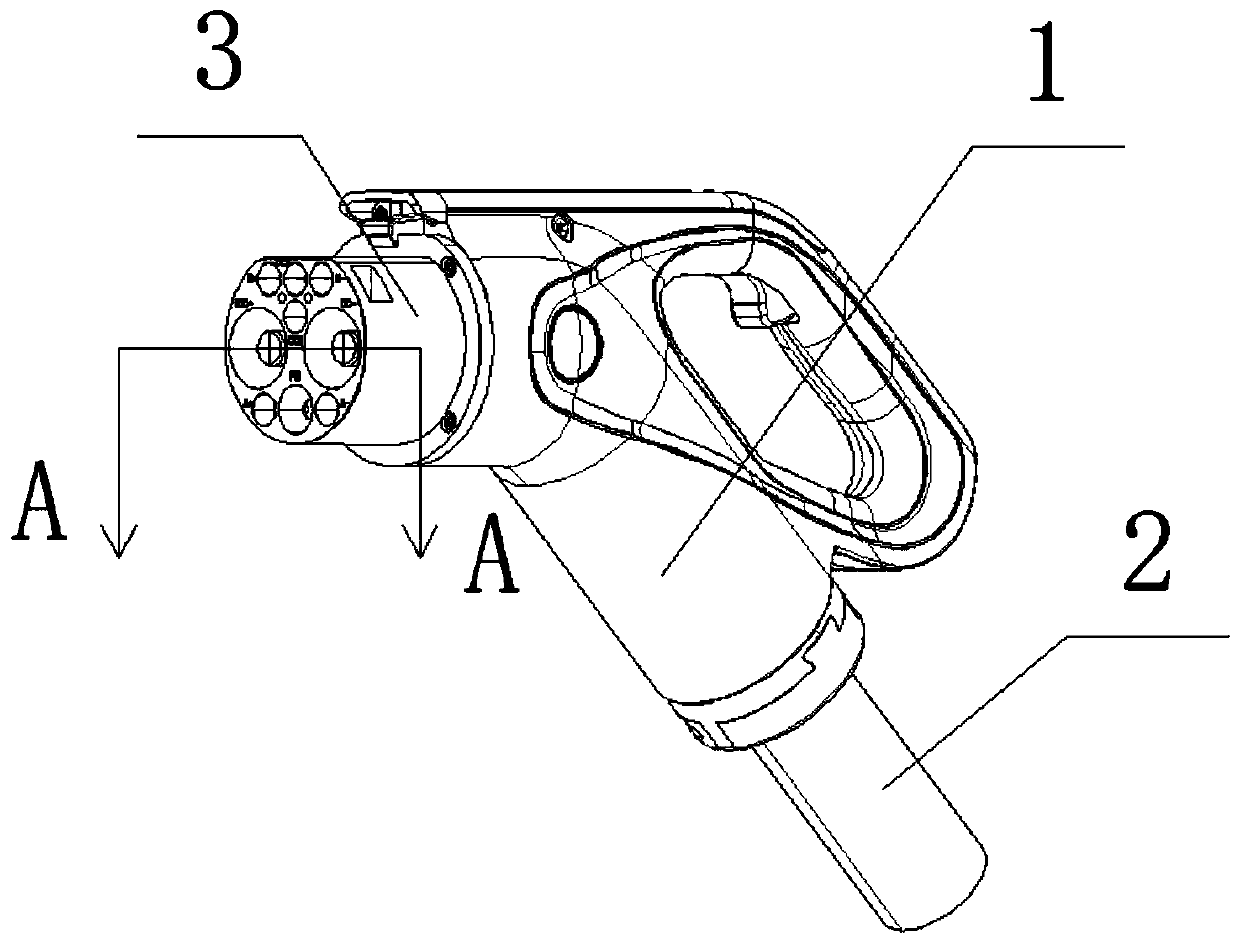

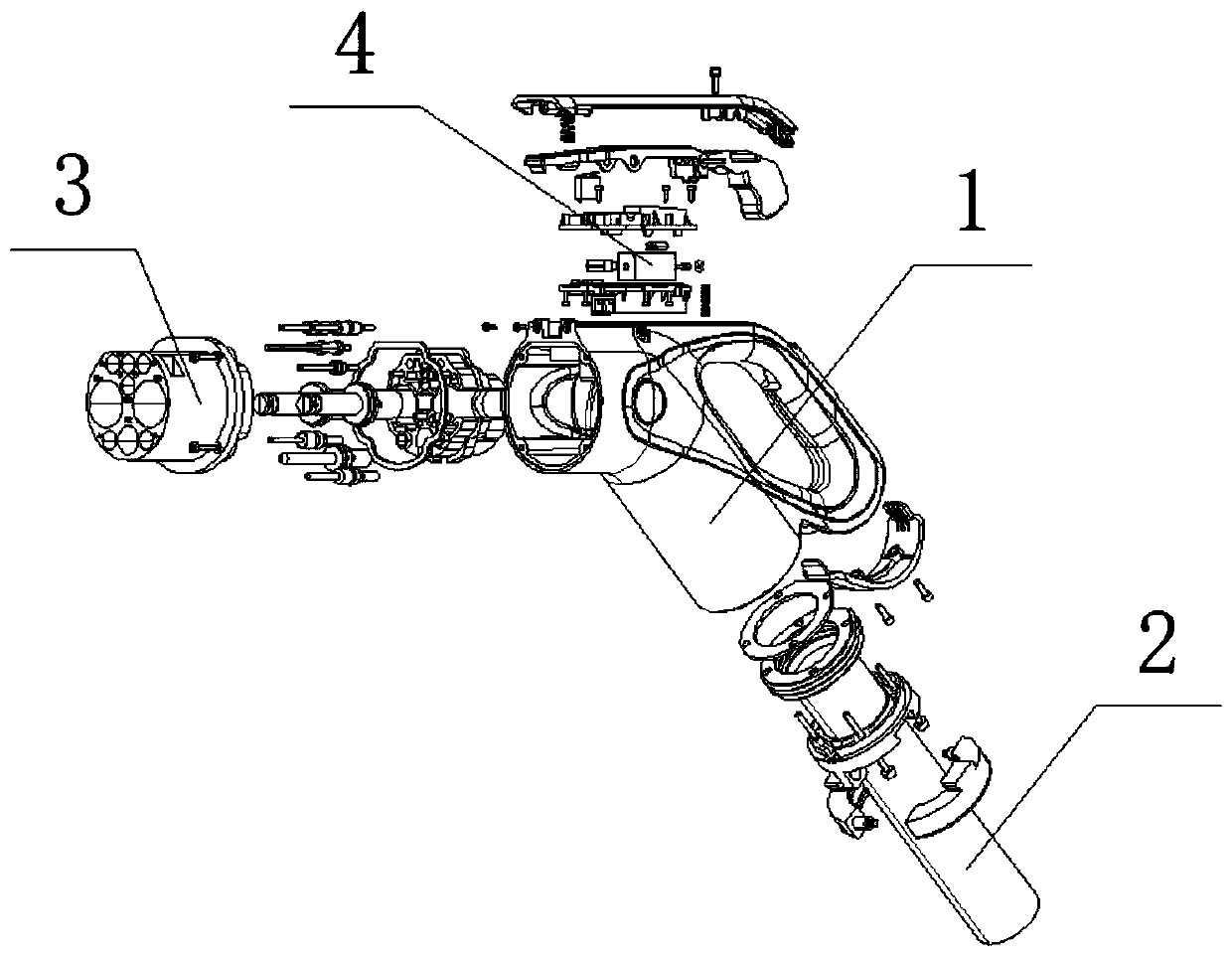

Charging gun module structure with high protection level

A module structure, charging gun technology, applied in charging stations, electric vehicle charging technology, circuits, etc., can solve problems such as micro switches, electromagnetic lock damage, electromagnetic lock copper wire short-circuit heating, damage, etc., to prevent spontaneous combustion problems , improve safety, improve airtight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

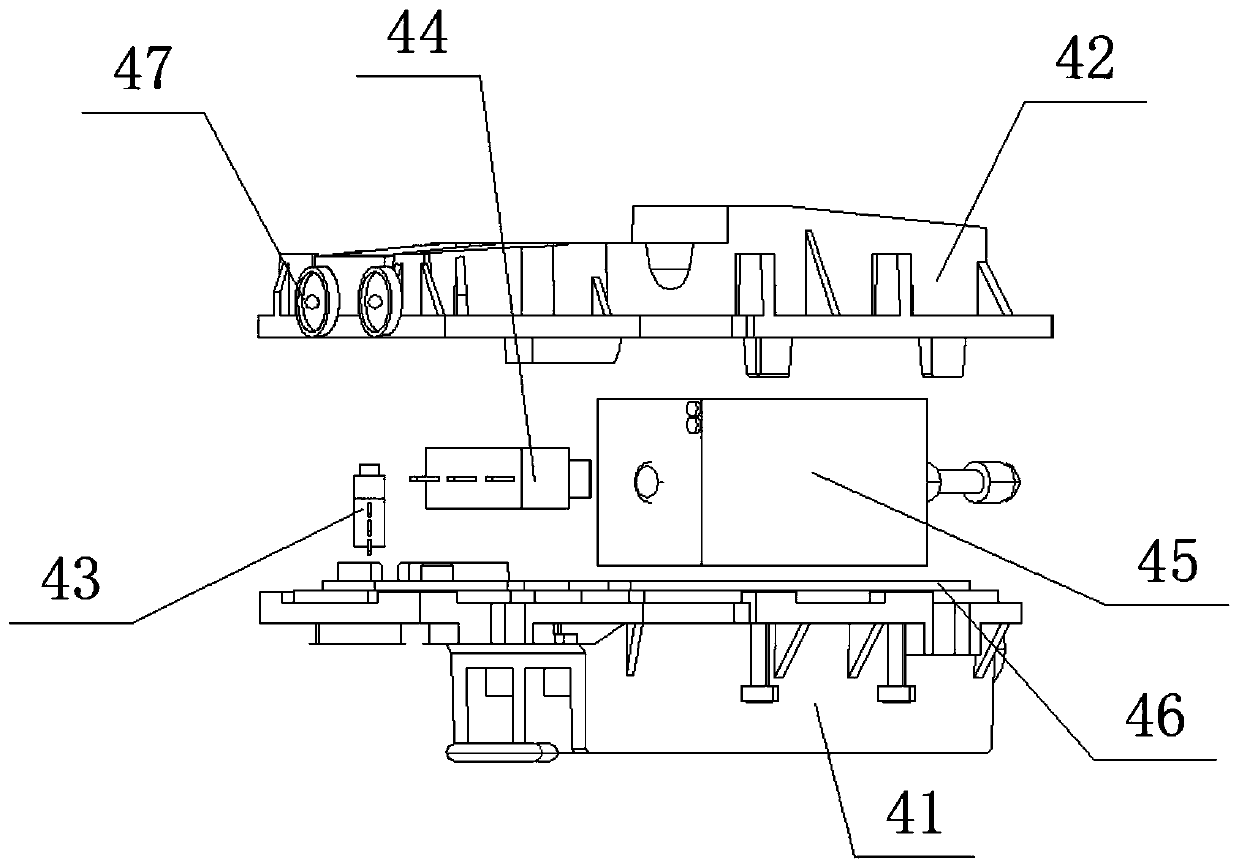

[0025] The connection between the high-voltage wire harness and the low-voltage wire harness used in the gun body 1 of the existing charging gun is very chaotic. Other external factors will cause the feedback switch 43, micro switch 44, and electromagnetic lock 45 in the charging gun body 1 to be damaged. Once the feedback switch 43, micro switch 44, and electromagnetic lock 45 are damaged, they will affect The circuit is short-circuited, and the electric core in the electromagnetic lock 45 is made of copper wire winding, which is very easy to cause situations such as heating and spontaneous combustion. In addition, when the DC+ / DC- of the charging gun is working at 250A / 750V, when the low-voltage wiring harness is close to DC+ / DC-, it will melt due to high temperature and cause short-circuit spontaneous combustion; the charging gun standard does not require this type of protection level, thus charging Most gun enterprises do not consider this point, so the feedback switch 43,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com