Self-locking joint for space truss structure connection

A technology of structural connection and space truss, which is applied to the connection of rods, connecting components, space navigation equipment, etc., can solve the problems of accidental risks, high requirements for robot operation control, and increase the difficulty of robot operation, etc. Operation accuracy and operation difficulty, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

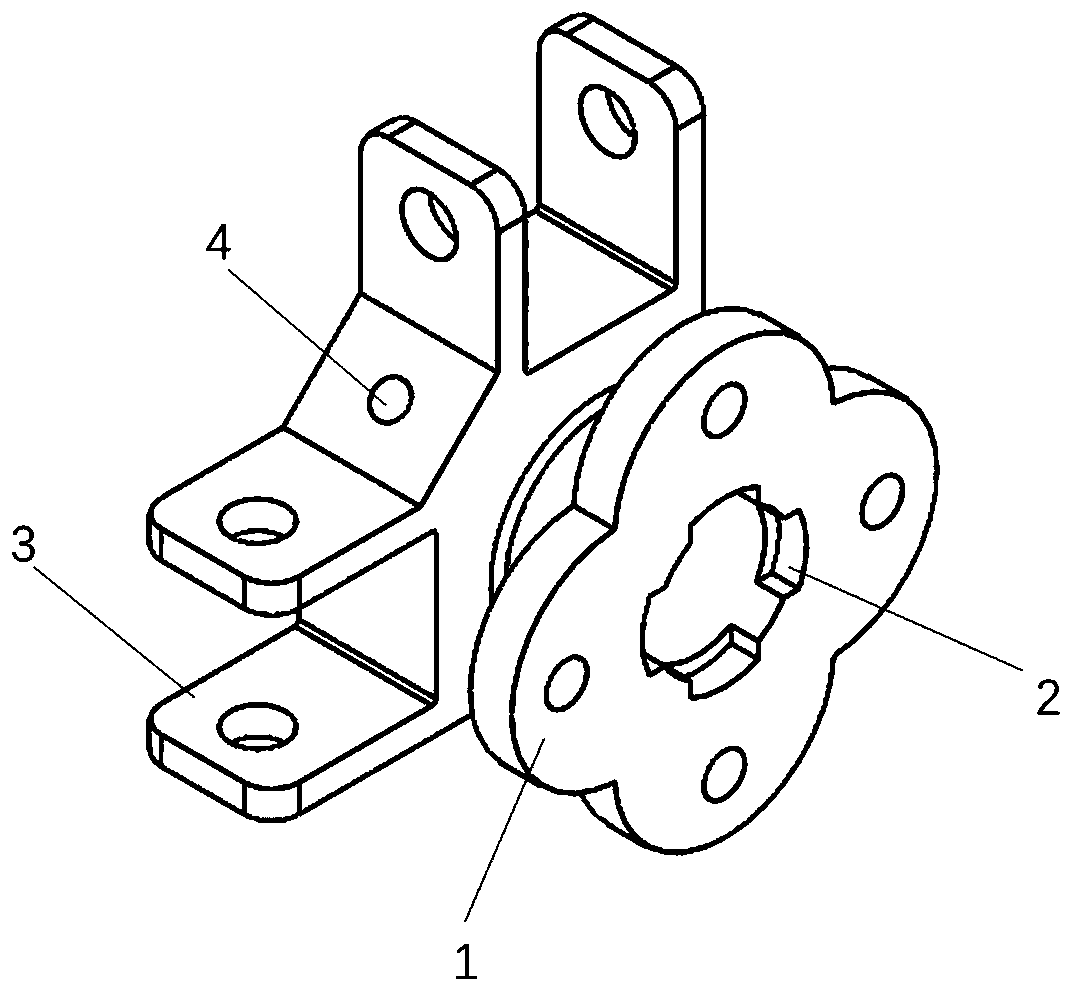

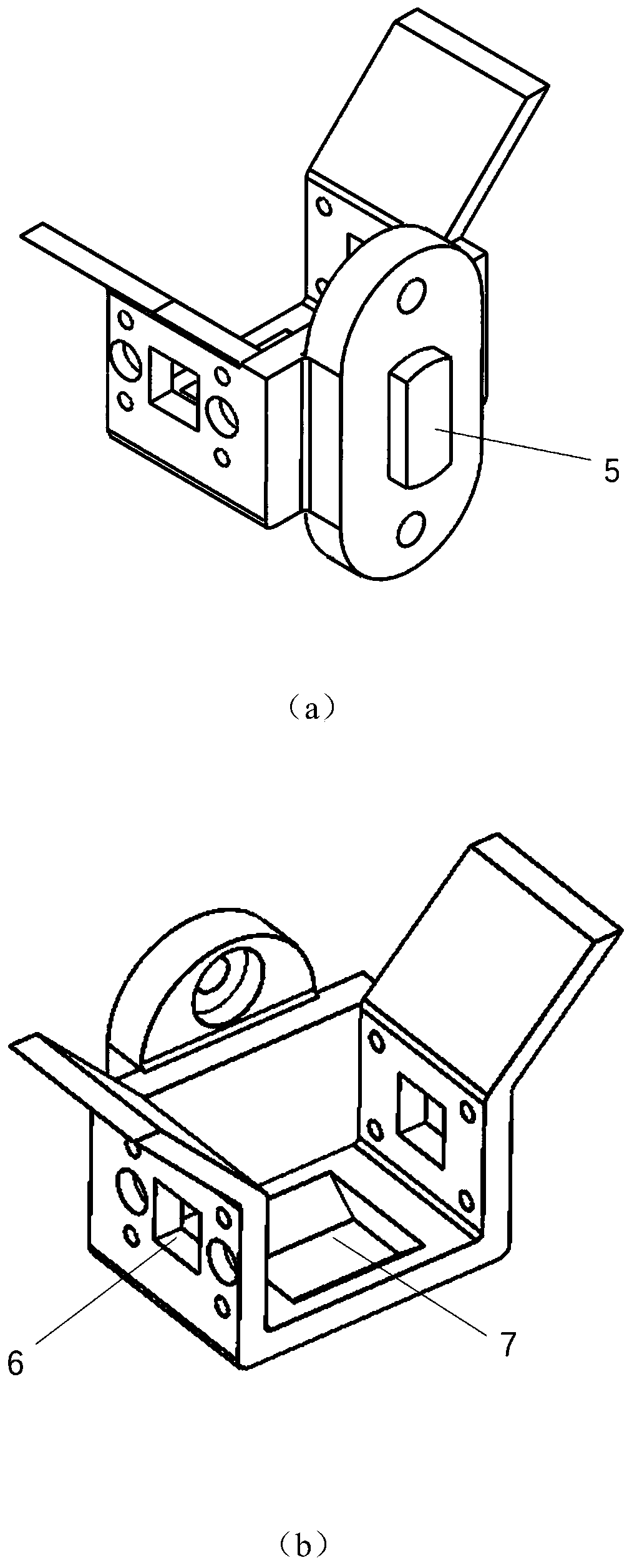

[0030] A self-locking joint used for the connection of space truss structures comprises a petal joint, a rotatable joint, two spring buttons and a bullet joint.

[0031] The petal joint includes an adapter piece 1 and an adapter piece. A through hole is provided in the center of the adapter piece 1 (1), and a through hole is provided in the middle of the adapter piece. Two bosses are arranged on the outer wall of the adapter piece, and the two bosses There is a 90-degree angle between the platforms, and a groove (3) is opened on each boss away from the through hole, and through holes are opened on the side walls on both sides of the groove, and the two through holes are coaxial, and the two bosses The plane formed by the axis of the through hole is perpendicular to the axis of the through hole in the middle of the adapter. A truss member is inserted int...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap