Valve load test system

A technology of load testing and valves, applied in the direction of mechanical valve testing, etc., can solve problems such as economic loss, pipeline stoppage, safety accidents, etc., and achieve the effect of improving performance reliability and avoiding huge losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

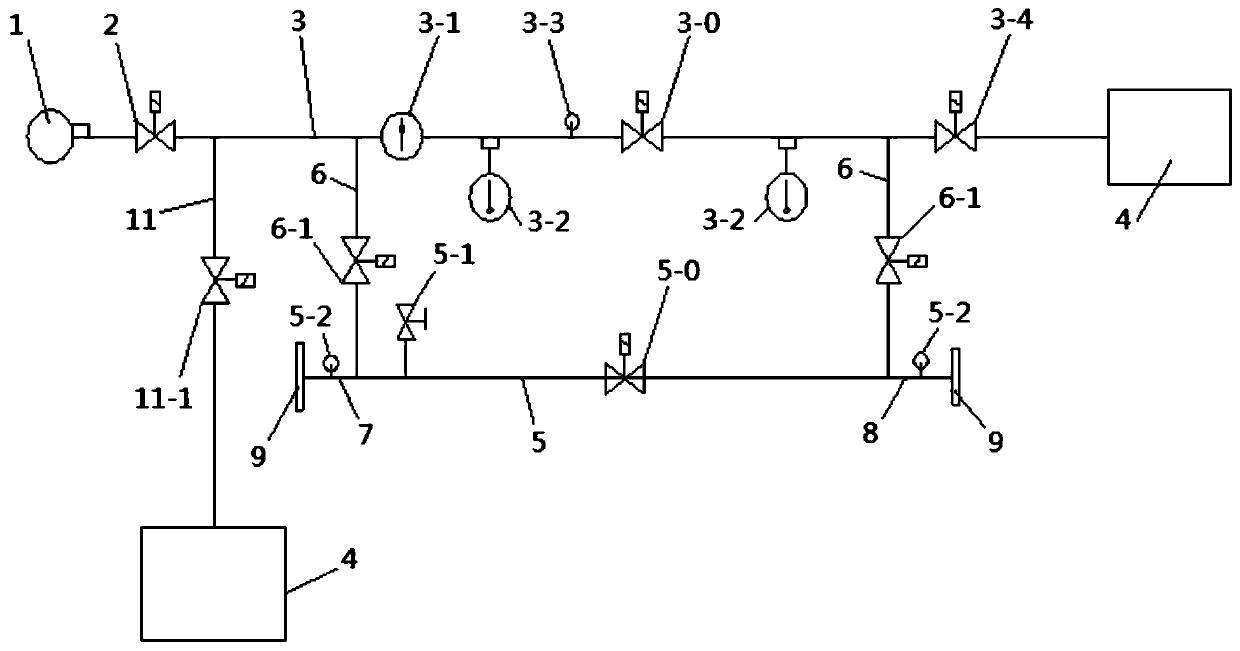

[0032] Such as figure 1 As shown, the test system of this embodiment is formed by connecting a working pump 1, a test main pipeline 3, a test branch pipeline 5 and related valves, wherein:

[0033] The inlet of the test main pipeline 3 is connected to the working pump 1, and the outlet is provided with a reservoir 4. The inlet and outlet of the test branch pipeline 5 are respectively connected to the main pipeline through the connecting pipeline 6, and the inlet of the test branch pipeline is also connected to the ball pipeline. 7. The outlet is connected with a ball receiving pipeline 8. At the same time, the inlet of the serving pipeline 7 and the outlet of the ball receiving pipeline 8 are respectively equipped with switchable mechanisms, specifically a quick-opening blind plate 9;

[0034] A pump outlet regulating valve 2 is installed at the outlet of the working pump; the first test valve installation position 3-0 is installed on the main test pipeline 3, and a flow meter...

Embodiment 2

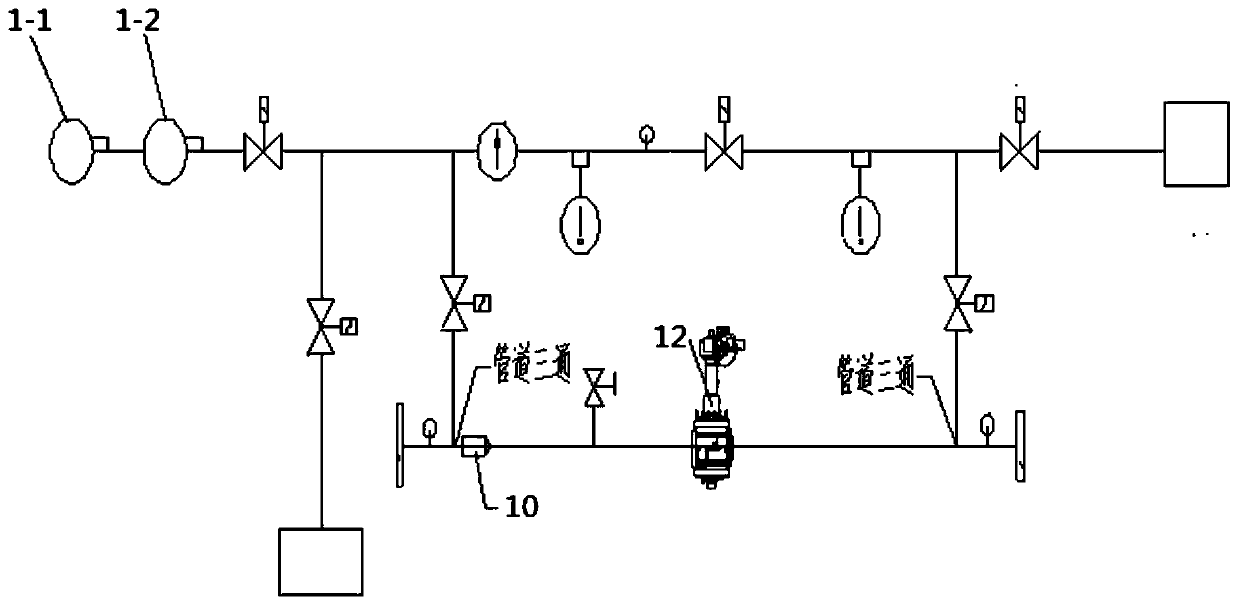

[0041] Another concrete test example, such as figure 2 As shown, the tested valve is the pigging ball valve 12, installed in figure 1 The 5-0 position is shown, and at the same time, the manual valve is installed at the 3-0 position; after that, the reliability of the ball passing through the pigging ball valve 12 under specified working conditions is tested, which can also be used to evaluate the impurity resistance of the pigging ball valve.

[0042] In this test example, combined with figure 1 and 2 As shown, the connecting pipeline of the service pipe, the inlet of the test branch pipeline and the corresponding end are connected through a pipe tee, and the ball collection pipeline, the outlet of the test branch pipeline and the connecting pipeline of the corresponding end are also connected through a pipe tee. The outlet of the ball pipeline is equipped with a quick-opening blind plate, and a pipe pig 10 is placed in the ball pipeline 7 and the ball collection pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com