Method for making regenerated two-layer cardboard paper by operating three-layer lapping paper machine

A paper machine and containerboard technology, applied in the field of papermaking, can solve problems such as single three-layer high-grammage containerboard, and achieve the effects of reducing wear and tear, reducing paper breaks and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

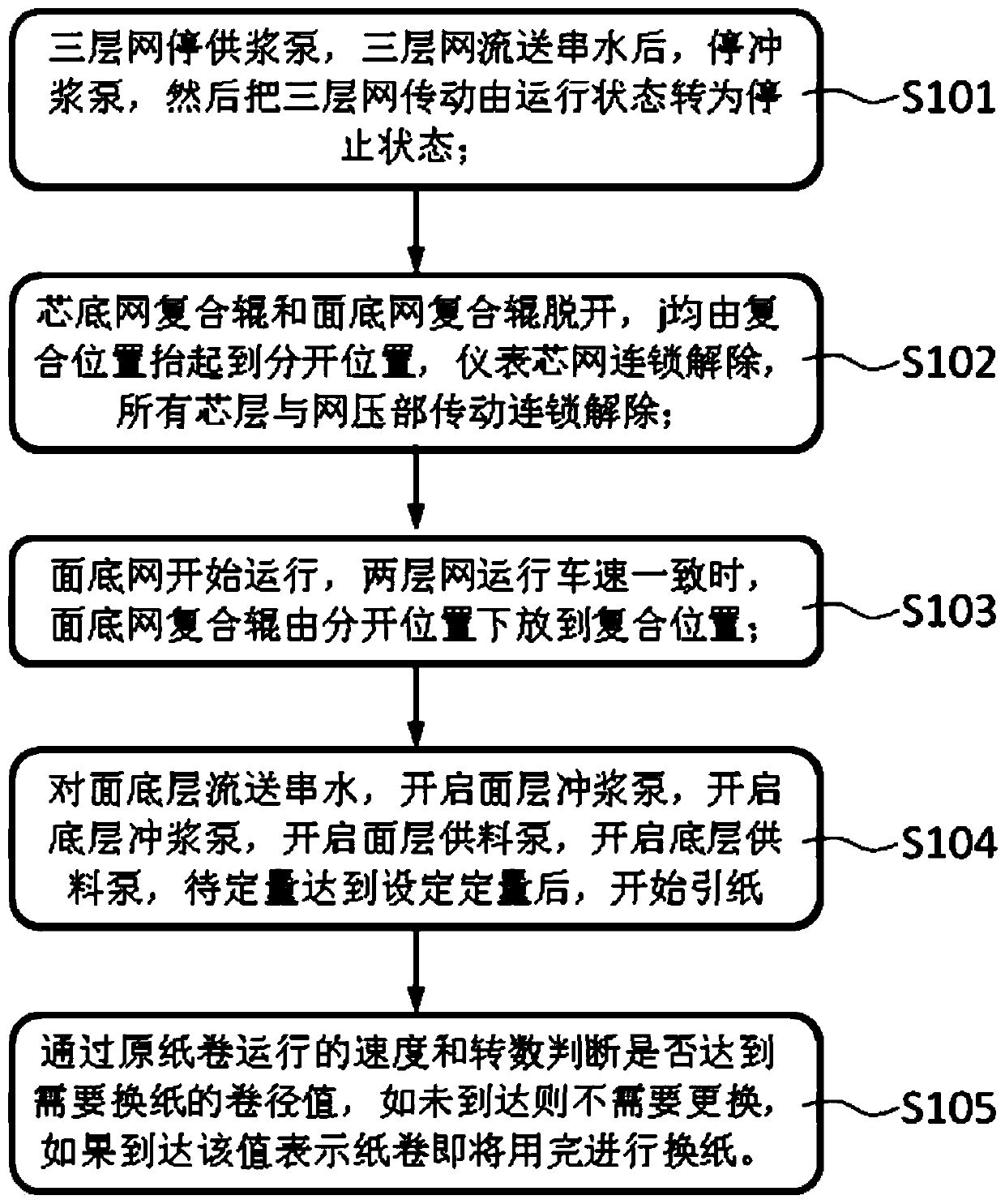

[0032] The method of operating the three-layer laminated wire paper machine in this embodiment to make recycled two-layer containerboard paper, taking the company's change of 190g high grammage paper to 120g low grammage paper as an example, includes the following specific steps:

[0033] Step S101. The three-layer wire paper machine runs at a speed of 1040m / min. When the paper machine is in normal operation, the three-layer wire stops the pulp supply pump. The running state changes to the stopped state;

[0034] Step S102, the composite roll of the core and bottom net is disengaged, the composite roll is lifted from the composite position to the separated position, the composite roll of the surface and bottom net is released, the composite roll is lifted from the composite position to the separated position, the interlocking of the instrument core net is released, and all core layers Interlocking with the transmission of the network pressure part is released to prevent the co...

Embodiment 2

[0040] The steps of this embodiment are basically the same as those of Embodiment 1. Taking the company’s change from 150g high grammage paper to 110g low grammage paper as an example, the method of operating a three-layer laminated paper machine to make recycled two-layer container board paper in this embodiment, Include the following specific steps:

[0041] Step S101, when the paper machine is in normal operation, the three-layer net stops the pulp supply pump, after the three-layer net flows through the water, stops the pulp pump, and then changes the three-layer net transmission from the running state to the stopped state;

[0042] Step S102, the composite roll of the core and bottom net is disengaged, the composite roll is lifted from the composite position to the separated position, the composite roll of the surface and bottom net is released, the composite roll is lifted from the composite position to the separated position, the interlocking of the instrument core net i...

Embodiment 3

[0047] The steps of this embodiment are basically the same as those of Embodiment 1. Taking the company’s change from 130g high grammage paper to 100g low grammage paper as an example, the method of operating a three-layer laminated paper machine to make recycled two-layer container board paper in this embodiment, Include the following specific steps:

[0048] Step S101, when the paper machine is in normal operation, the three-layer net stops the pulp supply pump, after the three-layer net flows through the water, stops the pulp pump, and then changes the three-layer net transmission from the running state to the stopped state;

[0049] Step S102, the composite roll of the core and bottom net is disengaged, the composite roll is lifted from the composite position to the separated position, the composite roll of the surface and bottom net is released, the composite roll is lifted from the composite position to the separated position, the interlocking of the instrument core net i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com