Rotary long-service-life multi-arc target and using method thereof

A rotary, long-life technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of uneven target surface, limited cooling effect, unsuitable for continuous coating production line, etc. Coating effect, stable control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

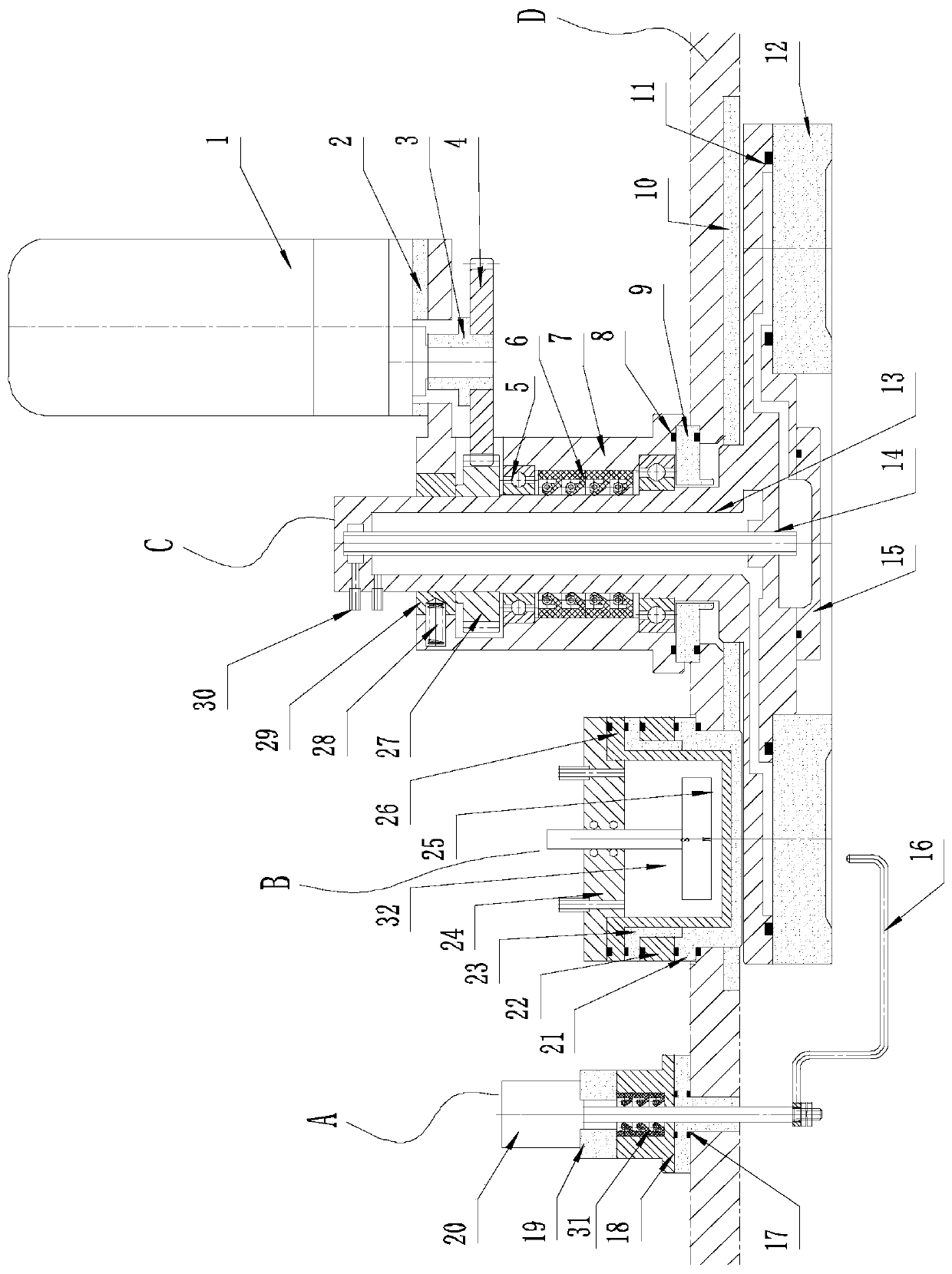

[0033] In this embodiment, a rotary long-life multi-arc target is suitable for continuous coating production, such as figure 1 As shown, it includes arc striking device A, anode device B and rotary arc target device C; the above-mentioned devices that make up the multi-arc target are respectively installed on the installation platform D in the coating chamber. The specific structure of each device is as follows:

[0034] The rotary arc target device includes an annular arc target 12 and a target rotation drive mechanism, the annular arc target is arranged at the output end of the target rotation drive mechanism, and the arc starting device and the anode device are respectively arranged on opposite sides of the annular arc target outside. The target rotation drive mechanism includes a rotation drive motor 1, a rotation drive gear set (comprising a meshed driving gear 4 and a driven gear 27), a rotation shaft seat 13 and a cooling assembly, and the output end of the rotation dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com