Rear shaft of chip removal machine

A chip removal machine and rear axle technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem of limited space in the chip removal machine housing, difficulty in installation and disassembly of the rear shaft of the chip removal machine, and The installation process is cumbersome and other problems, to achieve the effect of improving the efficiency of installation and disassembly, convenient and quick installation and disassembly, and convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

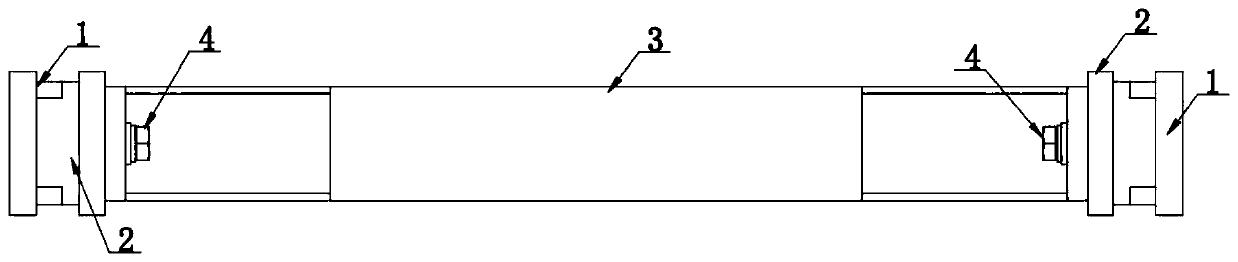

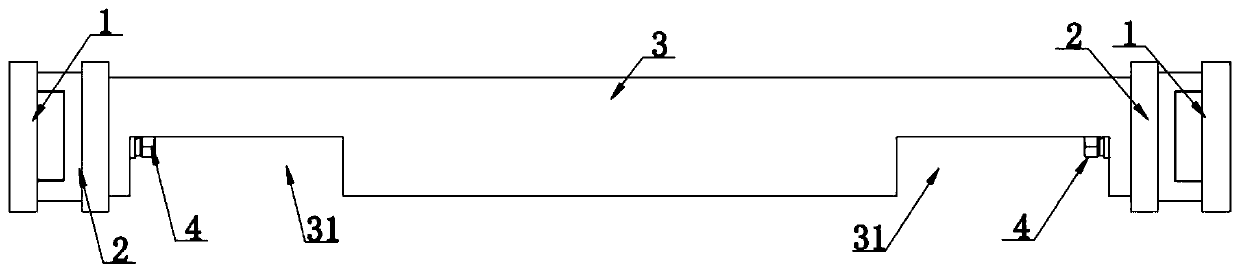

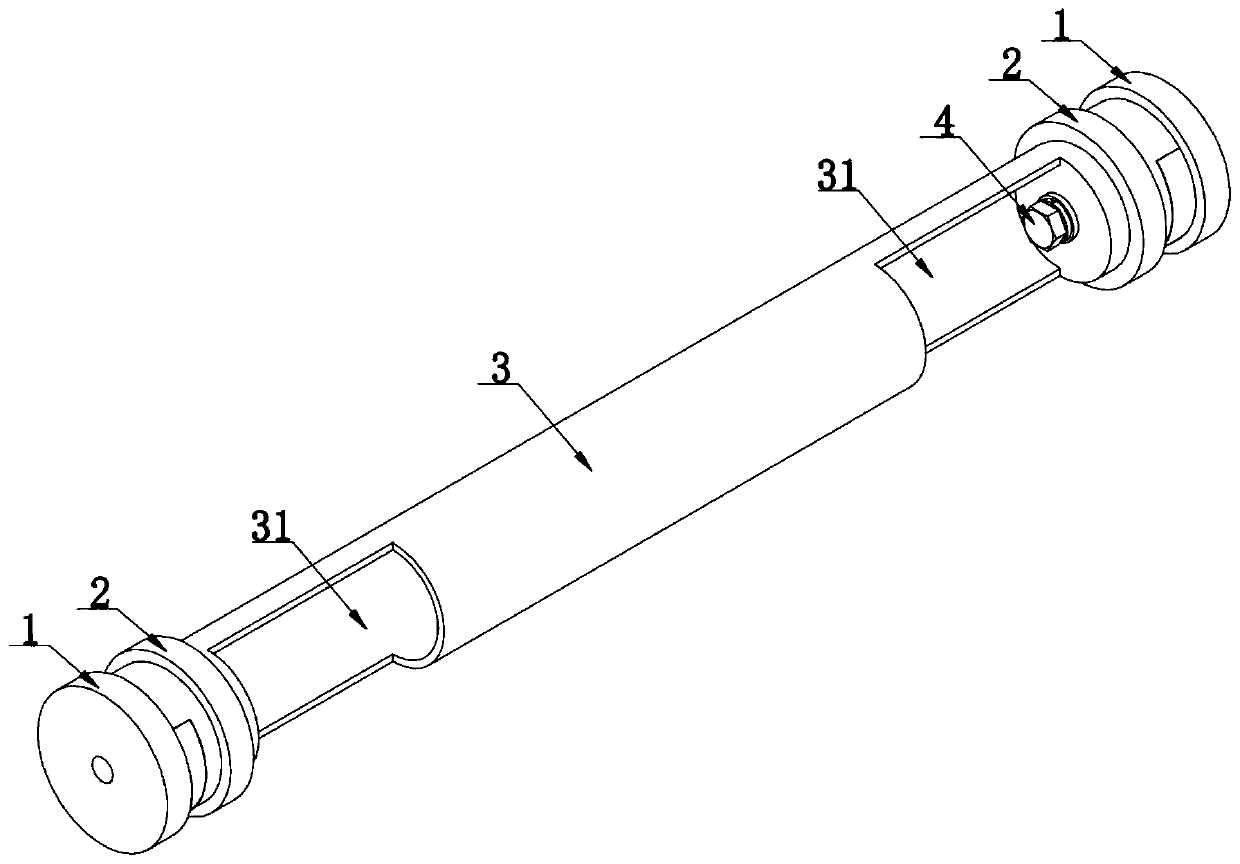

[0037] Such as Figure 1-Figure 7 As shown, a rear axle of a chip removal machine includes a support shaft 3 and a guide wheel assembly respectively arranged at both ends of the support shaft. The guide wheel assembly includes a guide wheel 2 and a fixing seat 1, and the fixing seat 1 is installed on On the machine housing 5, the guide wheel 2 is arranged between the fixed seat 1 and the support shaft 3, and the inner end surface of the fixed seat 1 is provided with a positioning boss 11 for positioning the guide wheel, The outer end surface of the guide wheel 2 is provided with a positioning groove 21 engaged with the positioning boss, the guide wheel 2 is provided with a mounting hole, and the support shaft 3 is provided with a The installation wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com