Cigarette filter capsule omni-directional reciprocating screening equipment, cigarette filter capsule omni-directional reciprocating screening method and detection and screening device

A screening device and screening equipment technology, applied in the direction of sorting, etc., can solve the problems affecting the use of users, the detection of popping beads defects, and the inability to guarantee the quality of popping beads for cigarettes, so as to improve the efficiency of screening and ensure the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

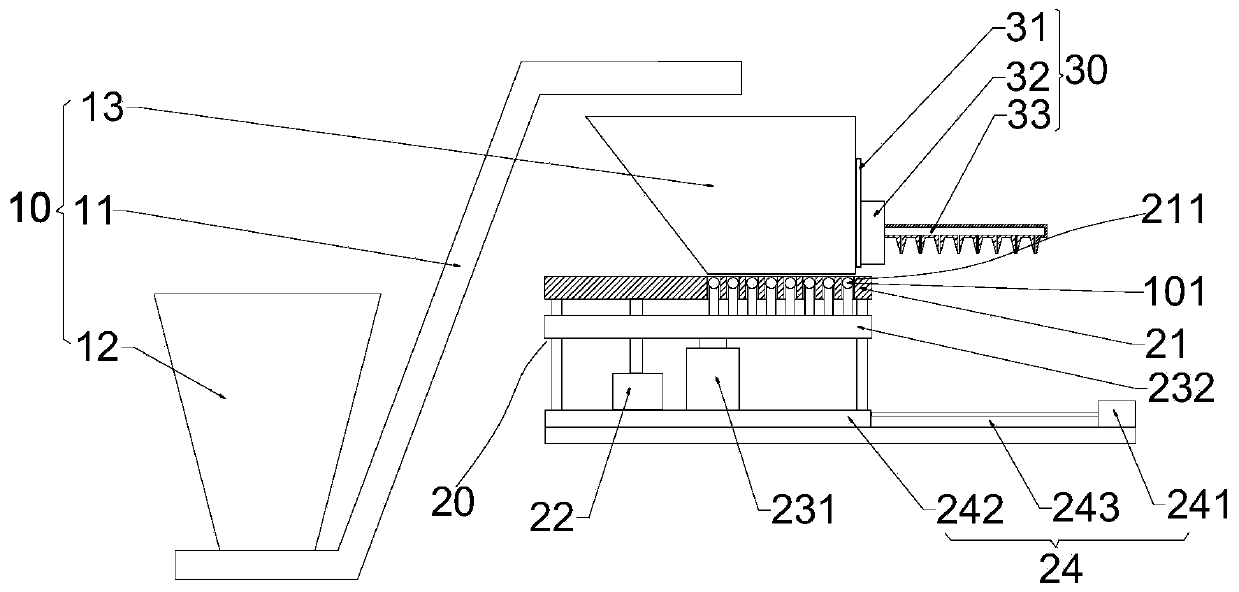

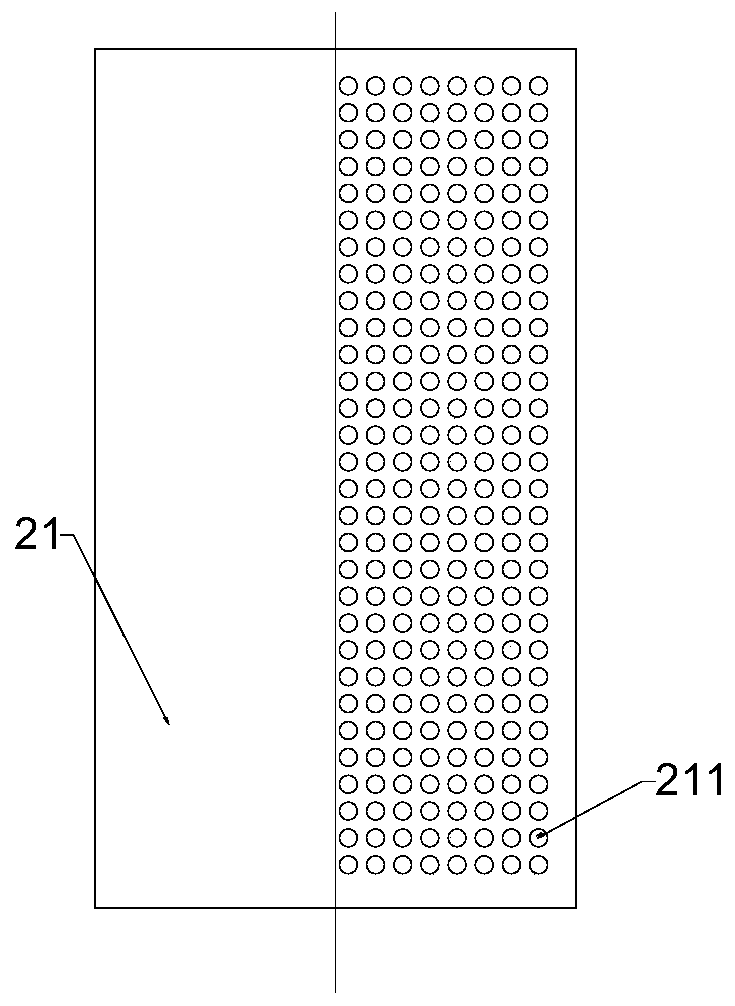

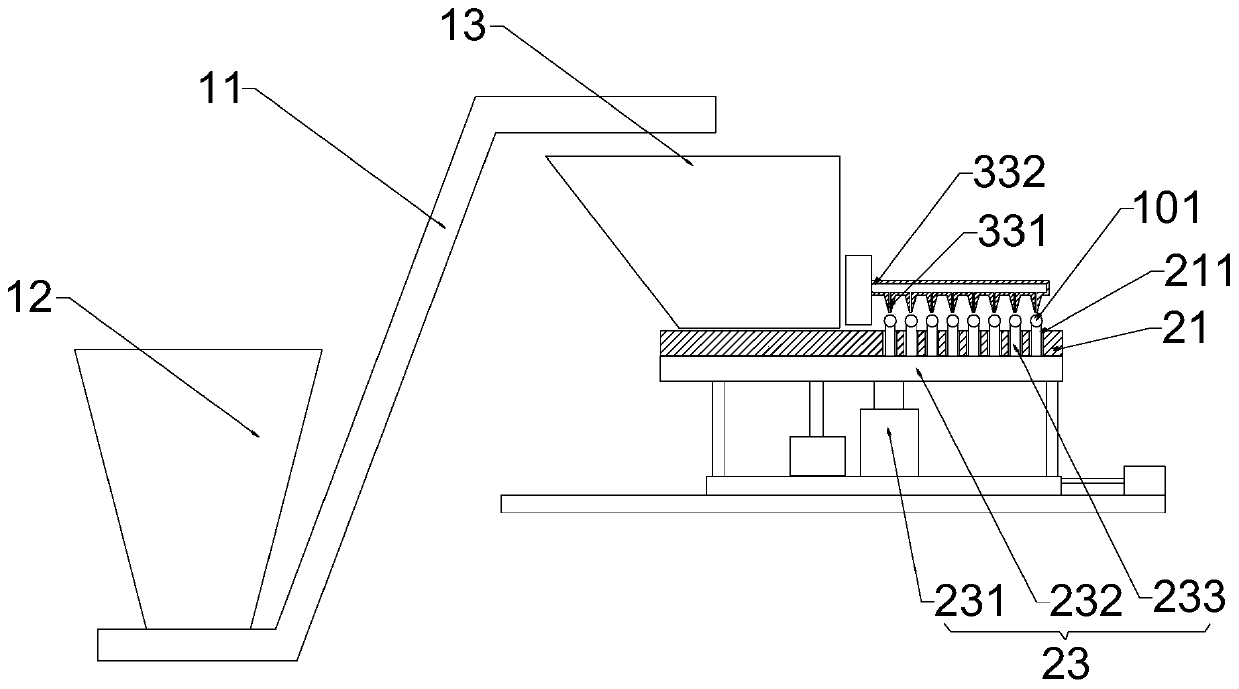

[0060] Such as figure 1 Shown is a schematic structural diagram of the all-round reciprocating screening device for cigarette popping beads described in the embodiment of the present invention.

[0061] Such as figure 1 As shown, an all-round reciprocating screening device for cigarette popping beads provided by the embodiment of the present invention includes a frame and a feeding device 10 , a positioning and sorting device 20 , a conveying device 30 and a detection and screening device 40 arranged on the frame , the detection and screening device 40 includes an upper detection mechanism 41 and a lower detection mechanism 42 .

[0062] The frame mainly plays the role of support, and is used to support components such as the feeding device 10, the positioning and sorting device 20, the conveying device 30, the detection and screening device 40, the upper detection mechanism 41 and the lower detection mechanism 42.

[0063] It should be noted that the omnidirectional recipro...

Embodiment 2

[0099] Such as Figure 5 and Figure 6 As shown, the embodiment of the present invention also provides an omnidirectional reciprocating screening method for cigarette popping beads, which is applied to the above-mentioned omnidirectional reciprocating screening device for cigarette popping beads, including the following steps:

[0100] Step S1. Using the feeding device to transport the workpiece to be measured to the positioning and sorting device;

[0101] Step S2. Positioning and sorting the workpieces to be measured by the positioning and sorting device;

[0102] Step S3. Suction the workpiece to be tested from the positioning and sorting device through the conveying device and transfer it to the detection and screening device for detection;

[0103] Wherein, the steps of using the detection and screening device to detect include:

[0104] Step S31. Use the first conveying device to absorb the workpiece to be tested from the positioning and sorting device at the first st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com