An automatic netting device for a baler

A baler and automatic technology, applied in the field of agricultural machinery, can solve problems such as poor working environment, low degree of automation, and dust entry, and achieve the effect of saving manpower and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

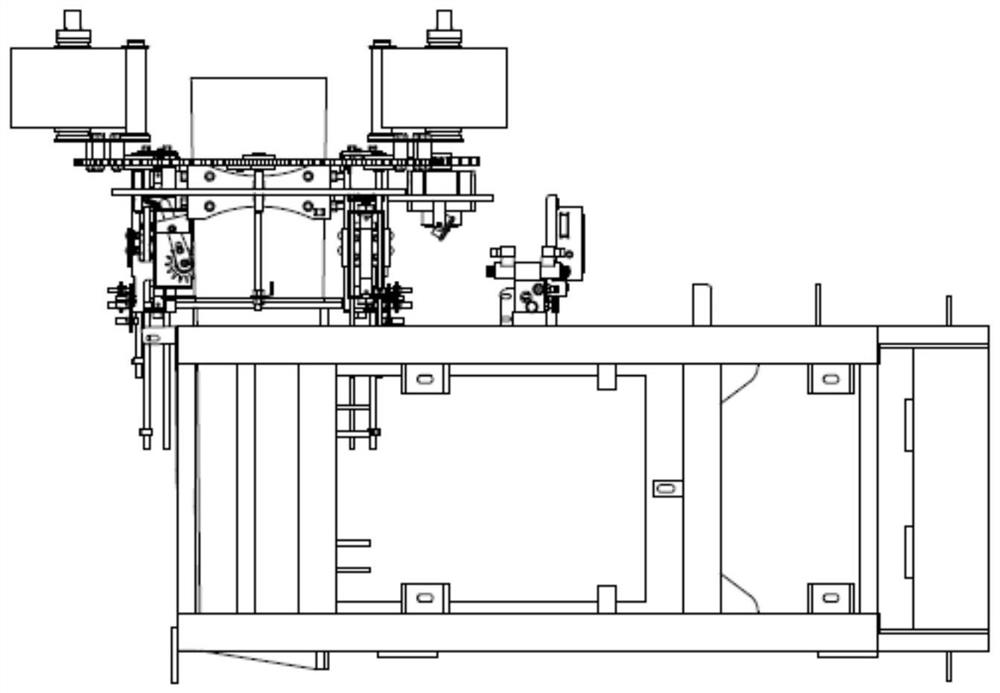

[0037] The technical solution of the present invention will be further explained and described below in the form of specific embodiments in combination with the accompanying drawings.

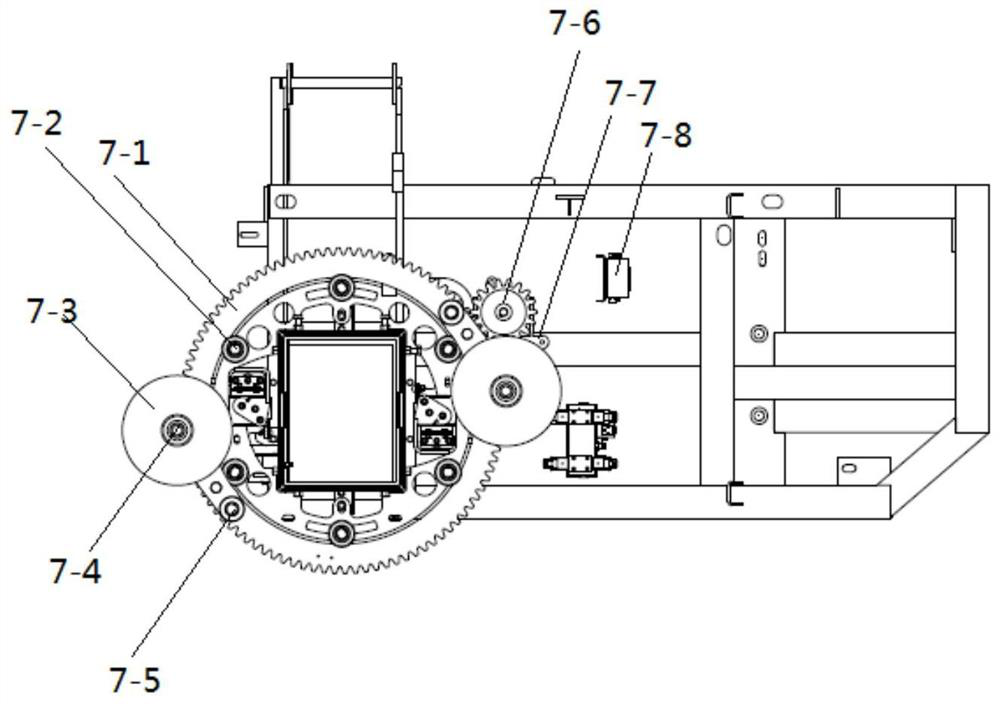

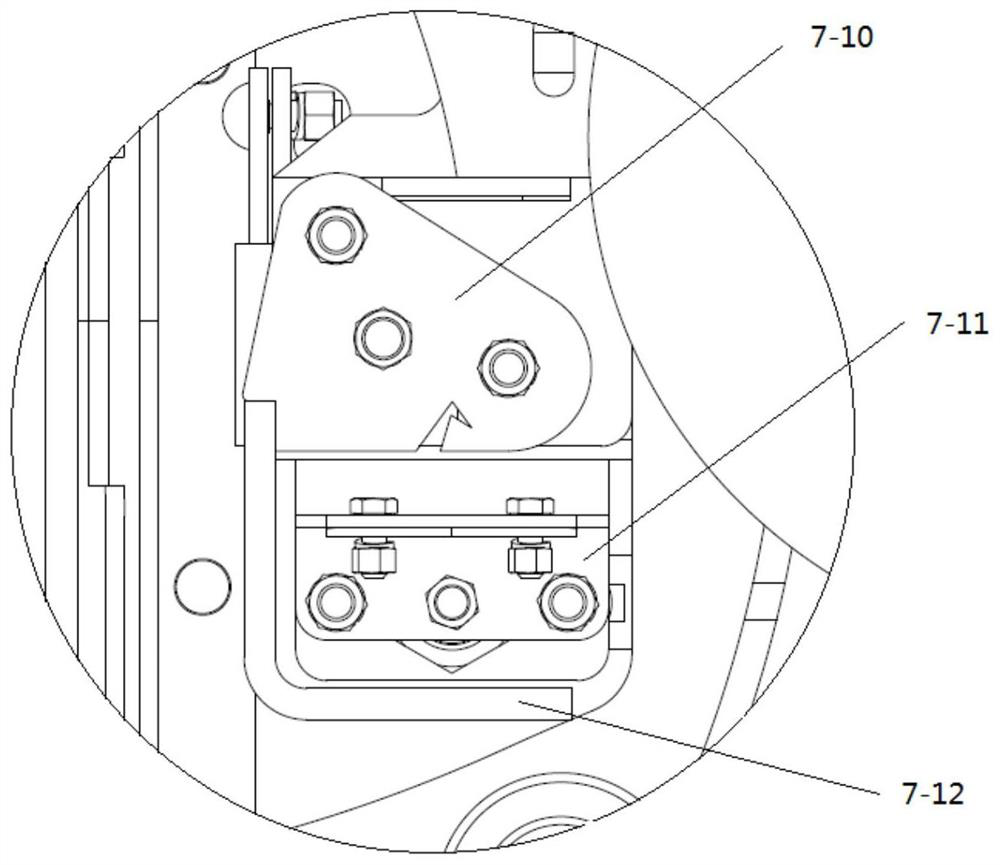

[0038] An automatic net winding device for a baler, mainly comprising: a large toothed plate 7-1, a toothed plate supporting roller 7-2, a net shaft 7-4, a net shaft 7-5, a pinion 7-6, Motor seat plate 7-7 and hydraulic motor 7-9;

[0039] The large toothed plate 7-1 is fixed on the toothed plate frame through a number of toothed plate supporting rollers 7-2, and the toothed plate frame is fixedly installed at the bale outlet of the baler. The large toothed plate 7-1 meshes with the pinion 7-6. The pinion 7-6 described above is a driving gear, which is connected with the hydraulic motor 7-9; the hydraulic motor 7-9 is fixed by the motor seat plate 7-7;

[0040] There are two network shafts 7-4 and two supporting net shafts 7-5 symmetrically arranged on the large toothed disc 7-1; the supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com