Hopper car for chain plate chip removal machine

A chain plate chip conveyor and material use technology, which is applied in the field of CNC machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

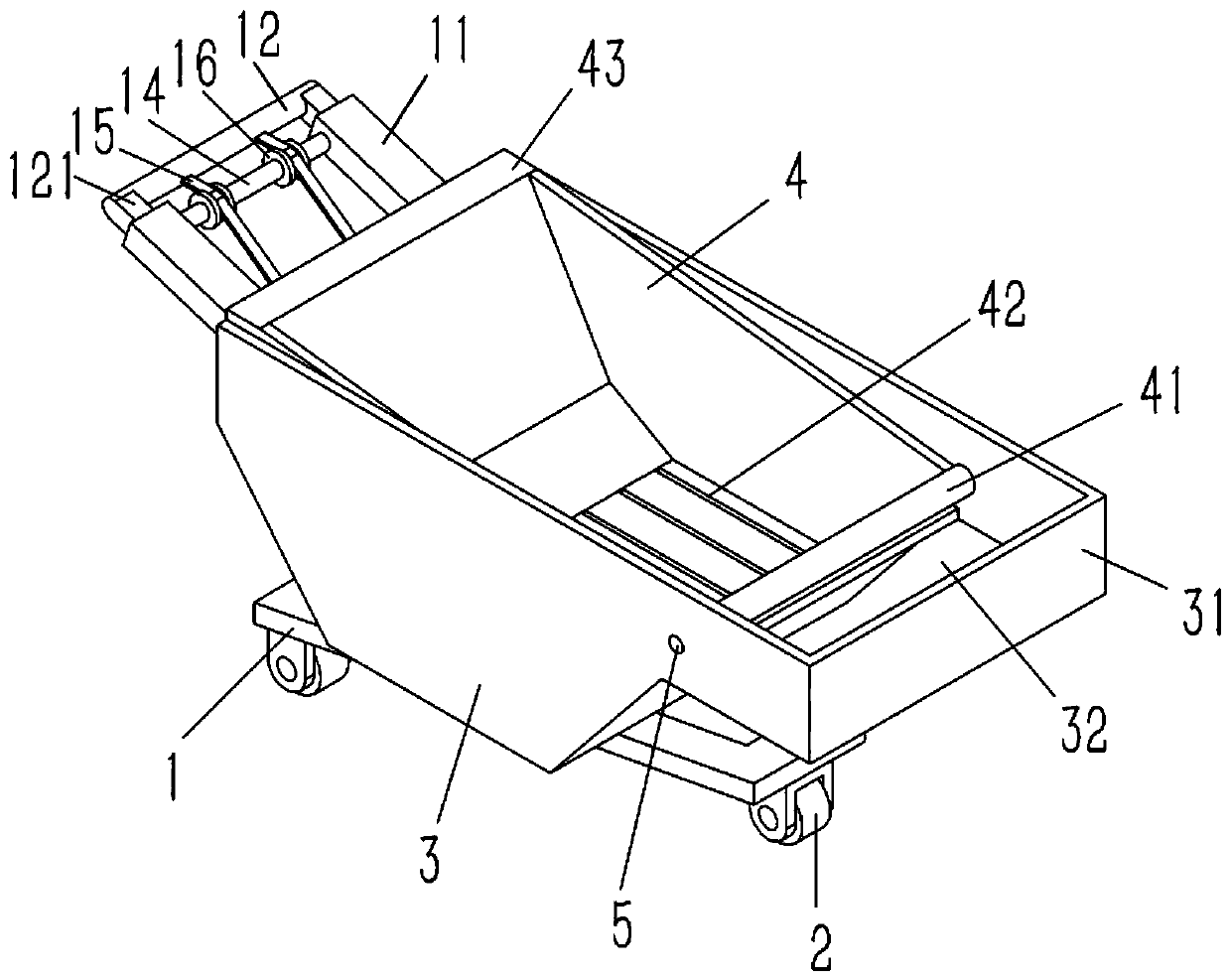

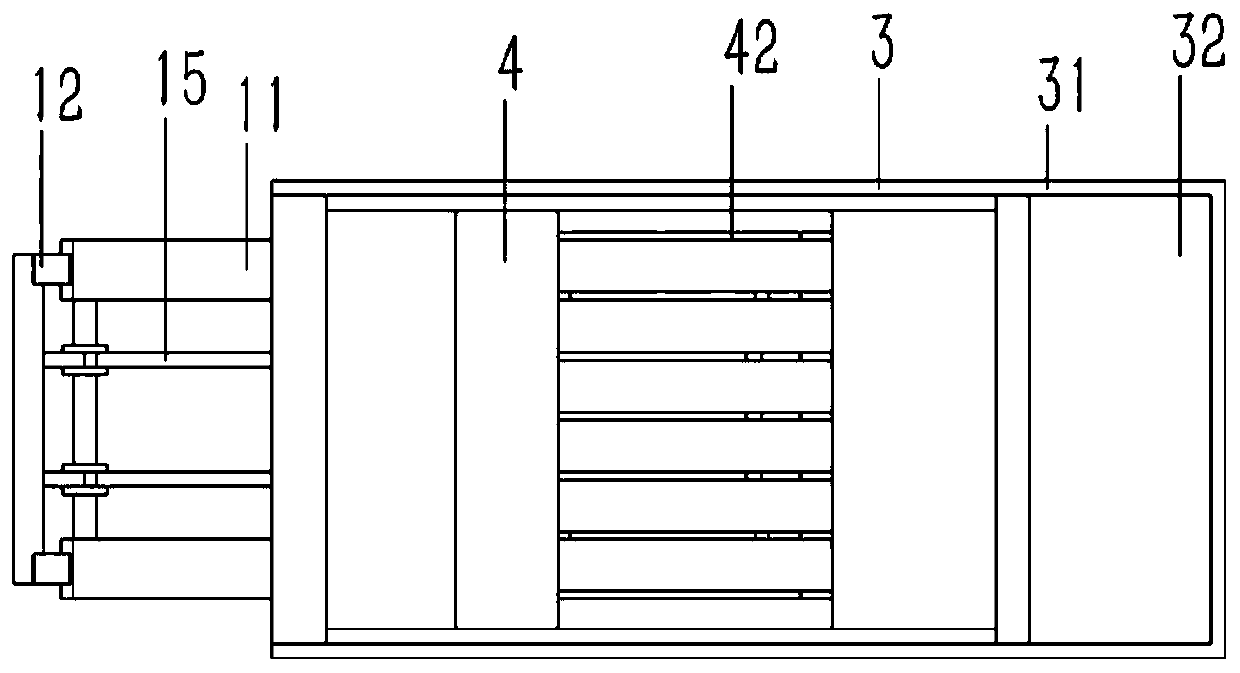

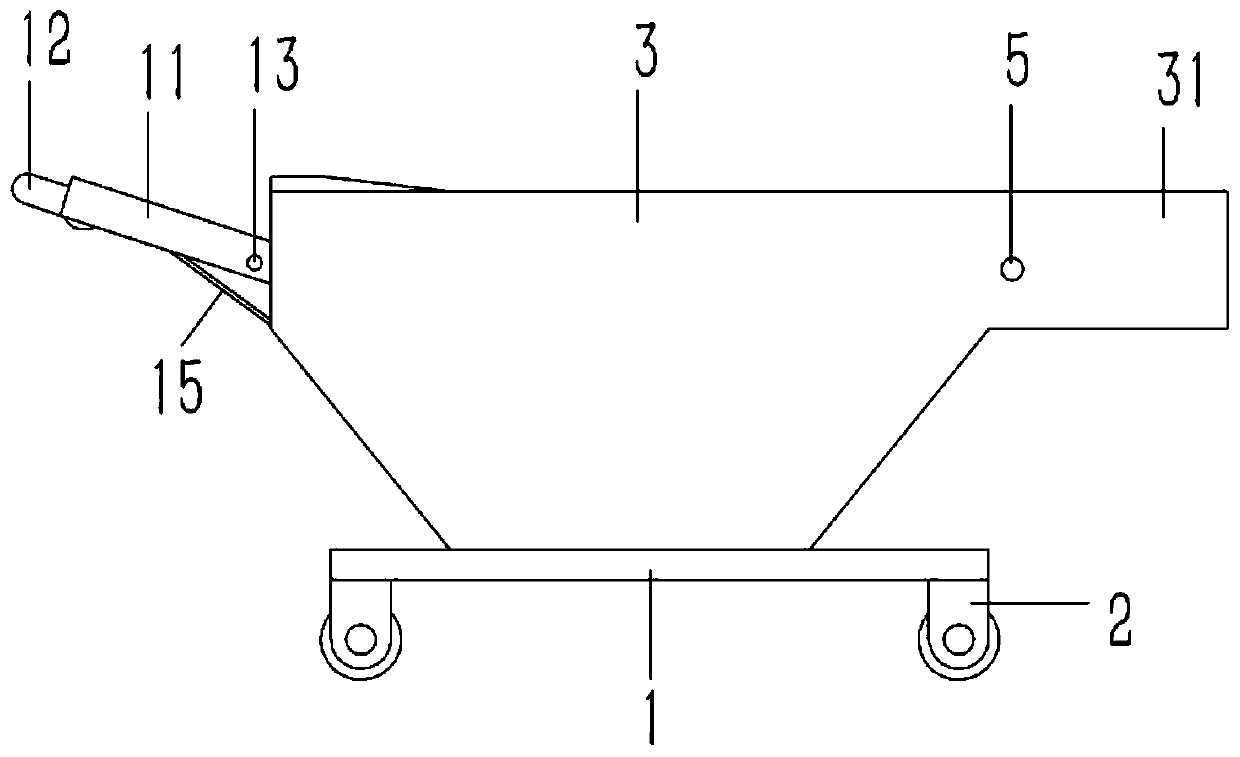

[0019] Example: see Figures 1 to 4 As shown, a hopper car for a chain plate chip removal machine includes a triangular base 1, a wheel 2 is fixed on the lower end surface of the base 1, an outer hopper 3 is fixed on the upper end surface of the base 1, and the outer hopper 3 is inserted with a The inner hopper 4, the outer hopper 3 or the front and rear end surfaces of the inner hopper 4 are inclined, and the upper end of the outer hopper 3 is formed with a material frame 31 extending forward, and the material frame 31 is formed with a discharge trough 32 that runs through the bottom surface of the material frame 31, The upper side of the front end of the inner hopper 4 is formed with a shaft sleeve 41, the shaft sleeve 41 is inserted into the material frame 31, and the shaft sleeve 41 is inserted with a support shaft 5, and the two ends of the support shaft 5 are hinged on the material frame 31 ; The bottom surface of the inner hopper 4 is formed with several strip-shaped dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com