Vibration sieve type saury body primary grading machine

A saury and sorting machine technology, applied in the field of fishing machinery, can solve the problems of few grading levels, inaccurate saury classification, and cumbersome machines, so as to relieve the burden of operation and improve the efficiency of size sorting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

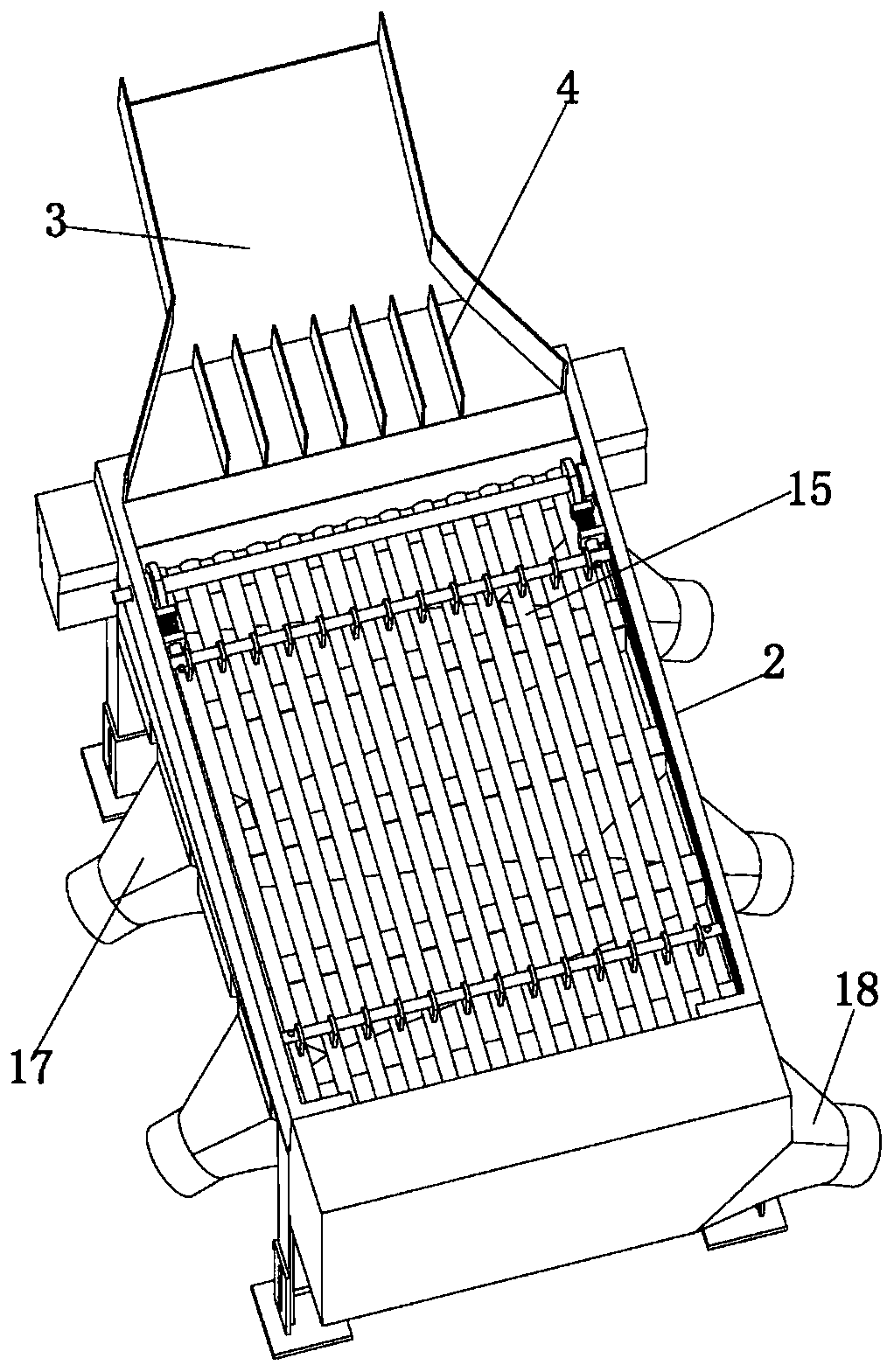

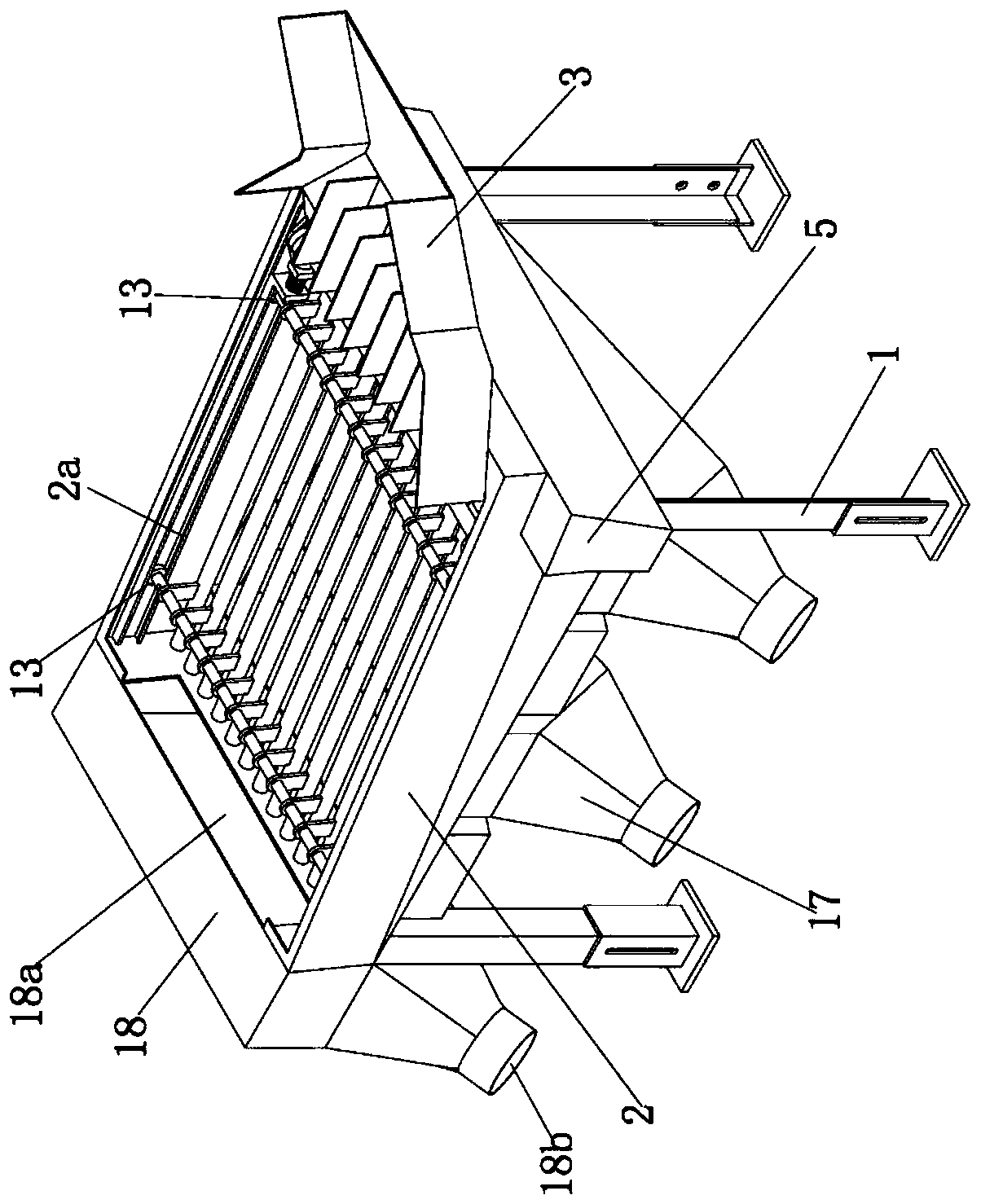

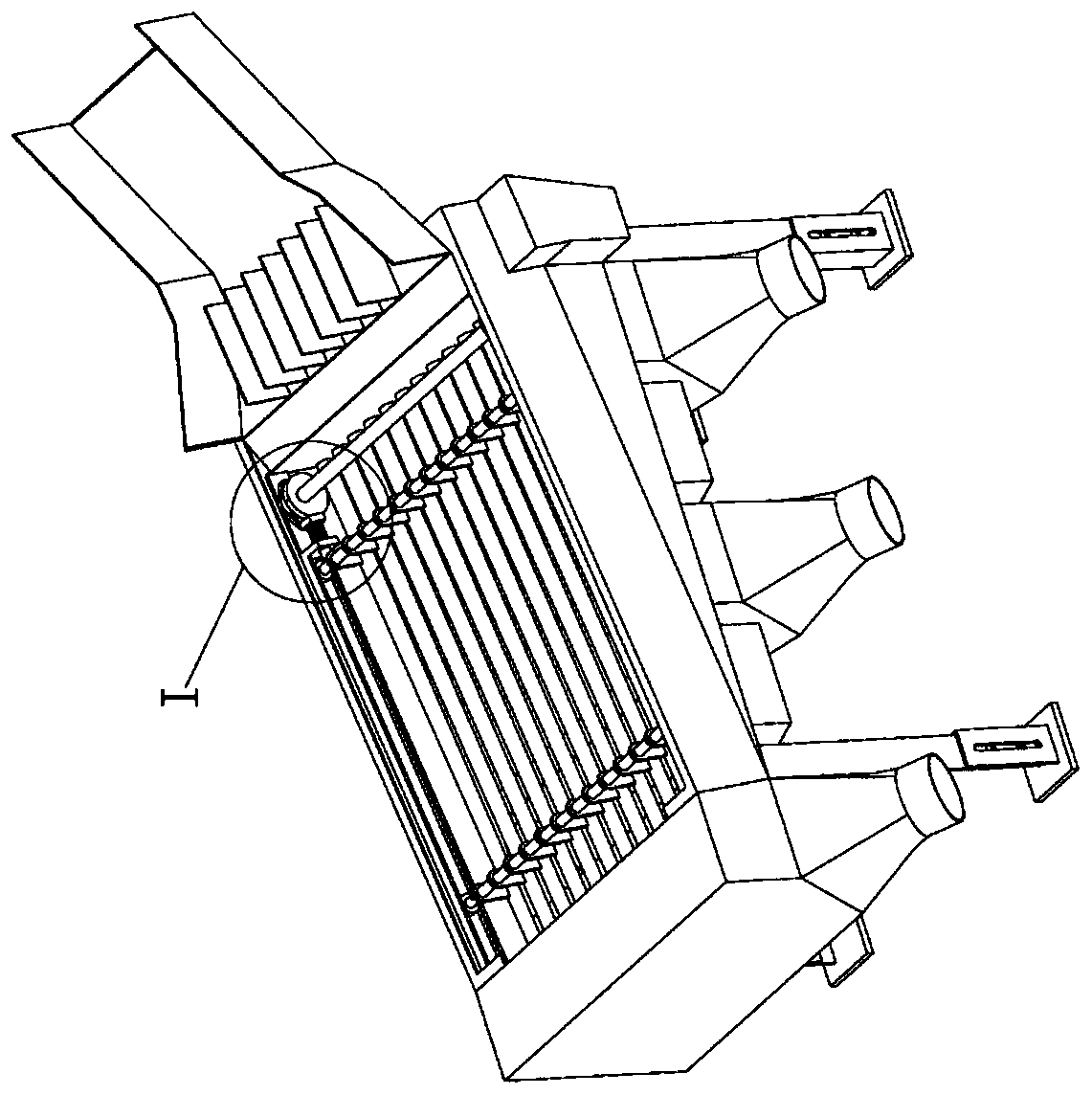

[0035] Attached below Figure 1-7 The present invention is further illustrated with specific examples.

[0036] like figure 1 , 6 Shown, a kind of vibrating sieve type saury fish body primary sorting machine, comprises frame 1, and is installed on the frame 1, upper and lower sides are the upper casing 2 of open structure, and upper casing 2 is with its The feed end is set to be inclined downward at 7°, and the inclination angle can be determined according to the site conditions.

[0037] The feeding end of the above-mentioned upper box body 2 is provided with a fish-feeding trough plate 3 arranged obliquely, and the lowest end of the fish-feeding trough plate 3 is fixedly connected with the feeding end of the upper box body 2 .

[0038] The inner cavity of the above-mentioned upper box body 2 is movably equipped with a screening rod assembly, and the outer wall of the upper box body 2 is installed with a driving part 5 that drives the screening rod assembly to move. The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com