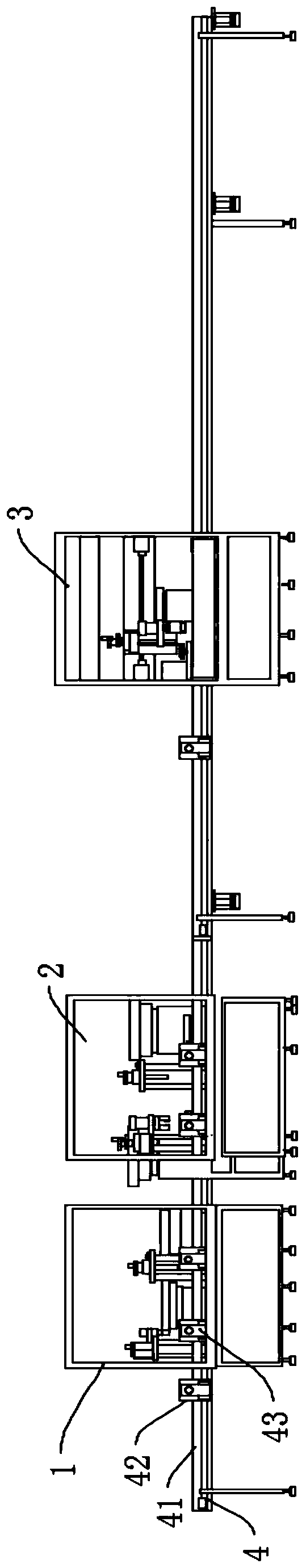

Full-automatic plug pressing, core pressing and cap screwing production line

A fully automatic, production line technology, applied in the directions of closed stoppers, stopper feeding, screw caps, etc., can solve the problems of low work efficiency, increase labor costs, affect work efficiency, etc., achieve high work efficiency, and reduce the use of manpower and material resources. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

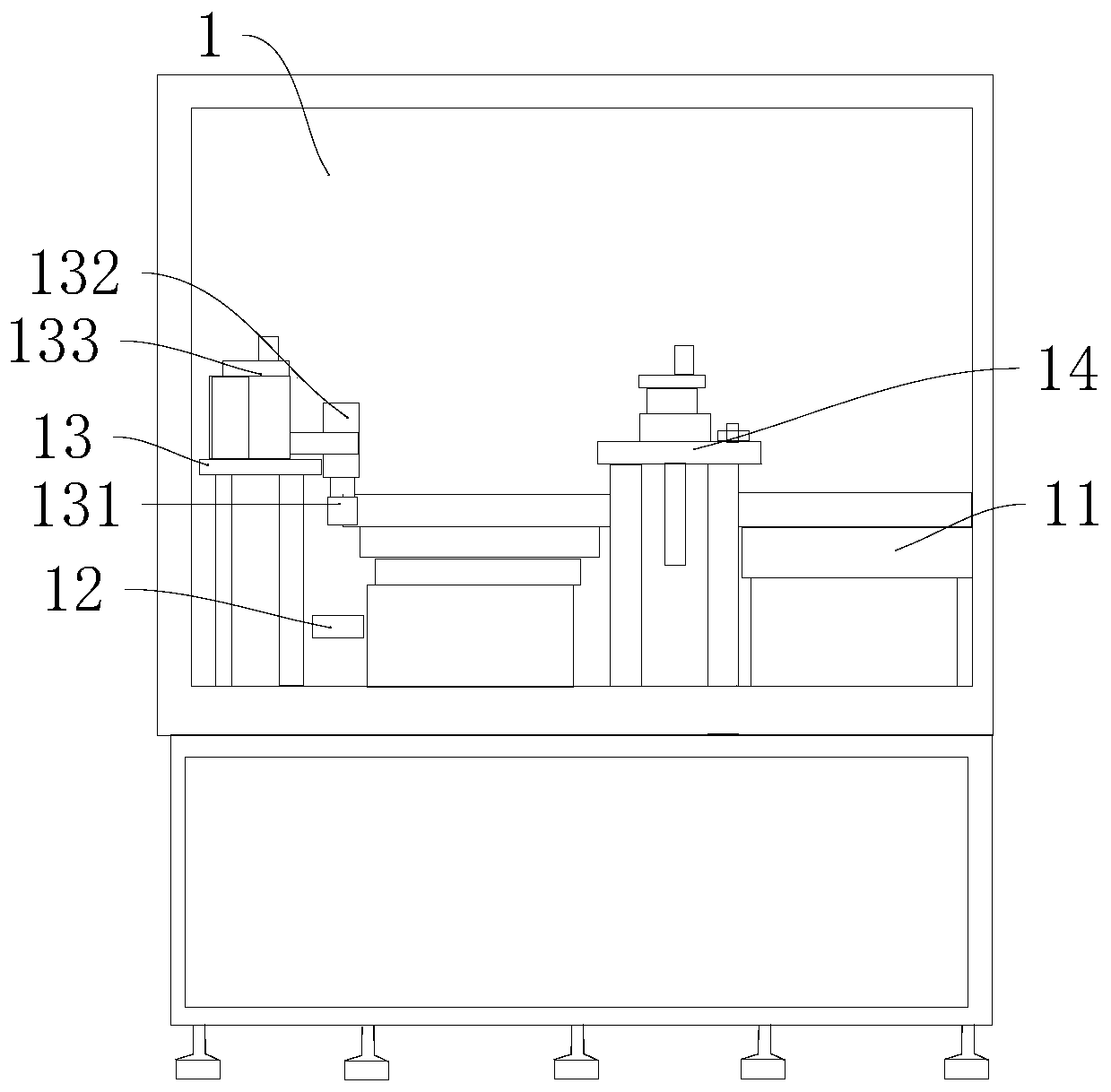

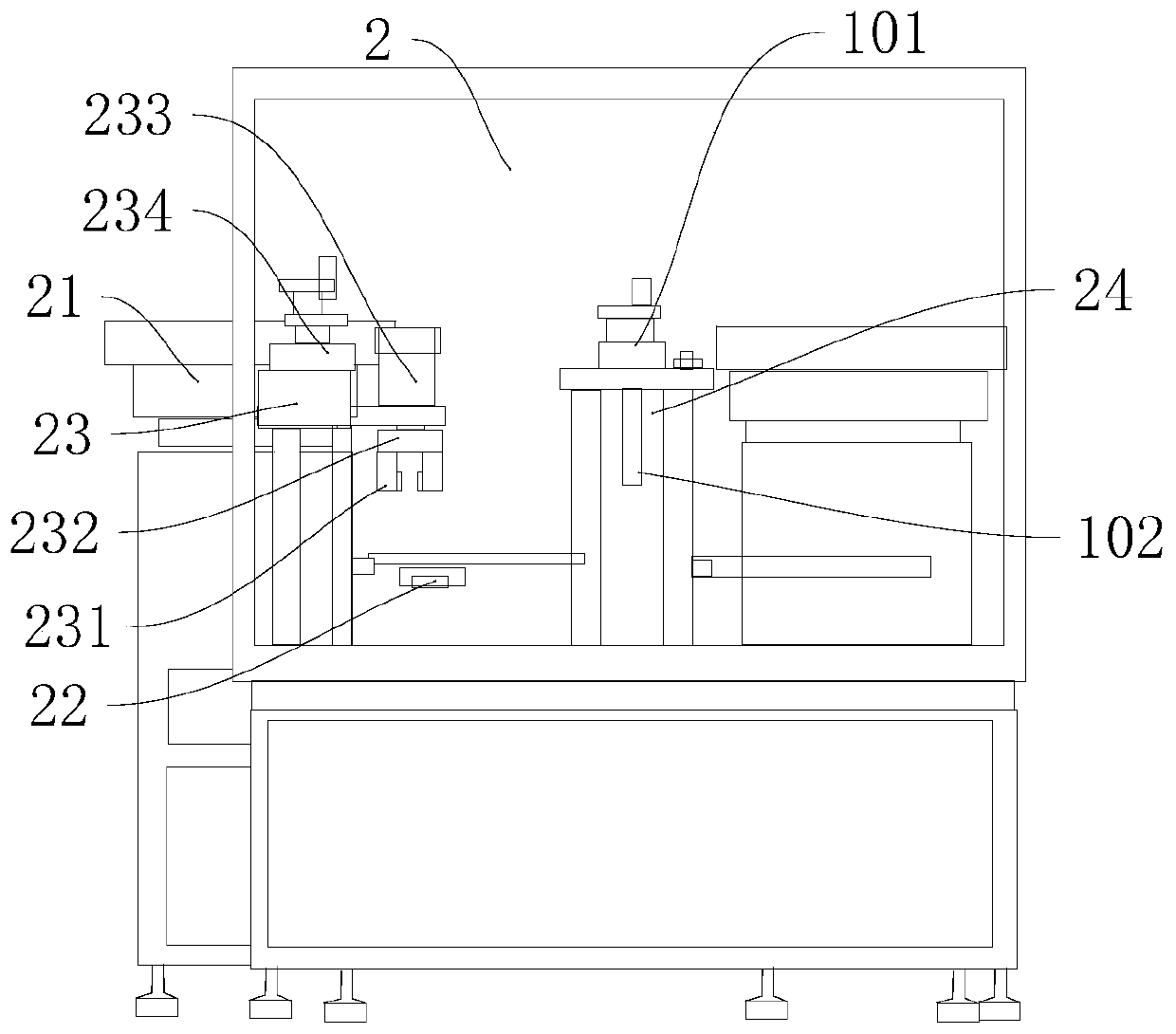

Embodiment example 1

[0040] In this implementation case, the conveyor belt 4 is also connected to the filling machine, and the filling bottle sensor 331, the bottle separating sensor 421 and the bottle blocking sensor 431 are infrared sensors or photoelectric switches, and the end of the lower end of the bottle pressing bar 103 is Soft rubber material.

[0041] working principle:

[0042] When the present invention is in use, a plurality of filling bottles filled with material liquid through the filling machine are conveyed via the conveyor belt 4, and when the filling bottles pass through the bottle separating mechanism 42 located in front of the automatic corking machine 1 on the conveyor belt 4, the bottles are separated The bottle-dividing sensing device 421 of mechanism 42 senses the first filling bottle, and the first filling bottle continues to be conveyed backward, and the bottle-dividing rod 423 of the bottle-dividing mechanism 42 is driven by the bottle-dividing cylinder 422 to stretch o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com