A wind tunnel test method for helicopter rotor model icing

A technology for helicopter rotor and wind tunnel testing, applied in the field of wind tunnel testing, can solve the problem that the experimental research has not been carried out effectively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

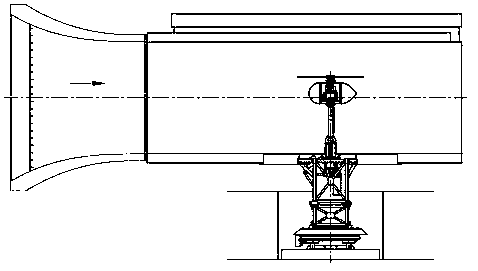

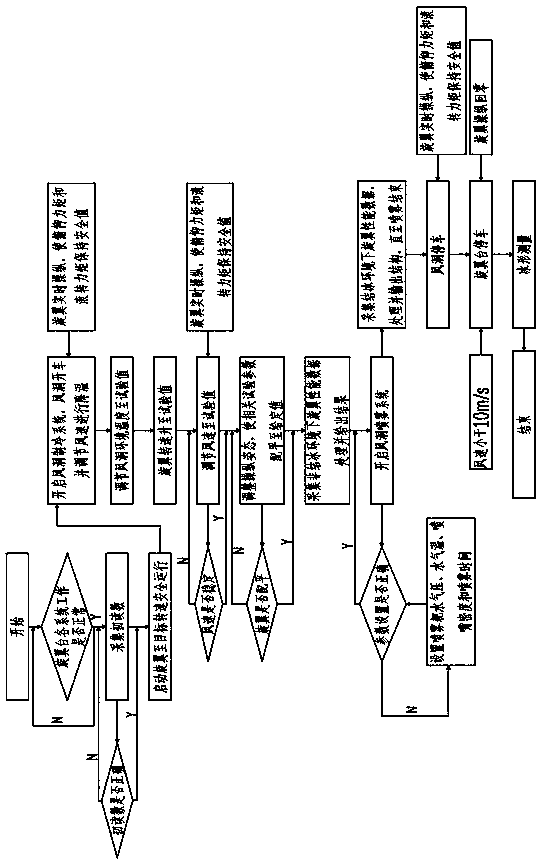

[0035] A kind of helicopter rotor model icing wind tunnel test method, such as figure 1 with figure 2 shown, including the following steps:

[0036] Step 1, each system of the rotor model test bench completes pre-test debugging, and after each system works normally, perform step 2;

[0037] Step 2, when the inclination angle of the rotor shaft is zero, collect the zero reading as the initial reading, if the initial reading is correct, go to step 3;

[0038] Step 3: Start the rotor for safe operation, then turn on the cooling system of the wind tunnel, start the wind tunnel, and adjust the wind speed to cool down. During the cooling process, the rotor is controlled in real time to keep the lift, pitch moment and roll moment of the rotor within a safe range. , after the ambient temperature of the wind tunnel drops to the test value and stabilizes, go to step 4;

[0039] Step 4: The rotor speed is increased to the test speed, and then the wind speed is adjusted to the test w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com