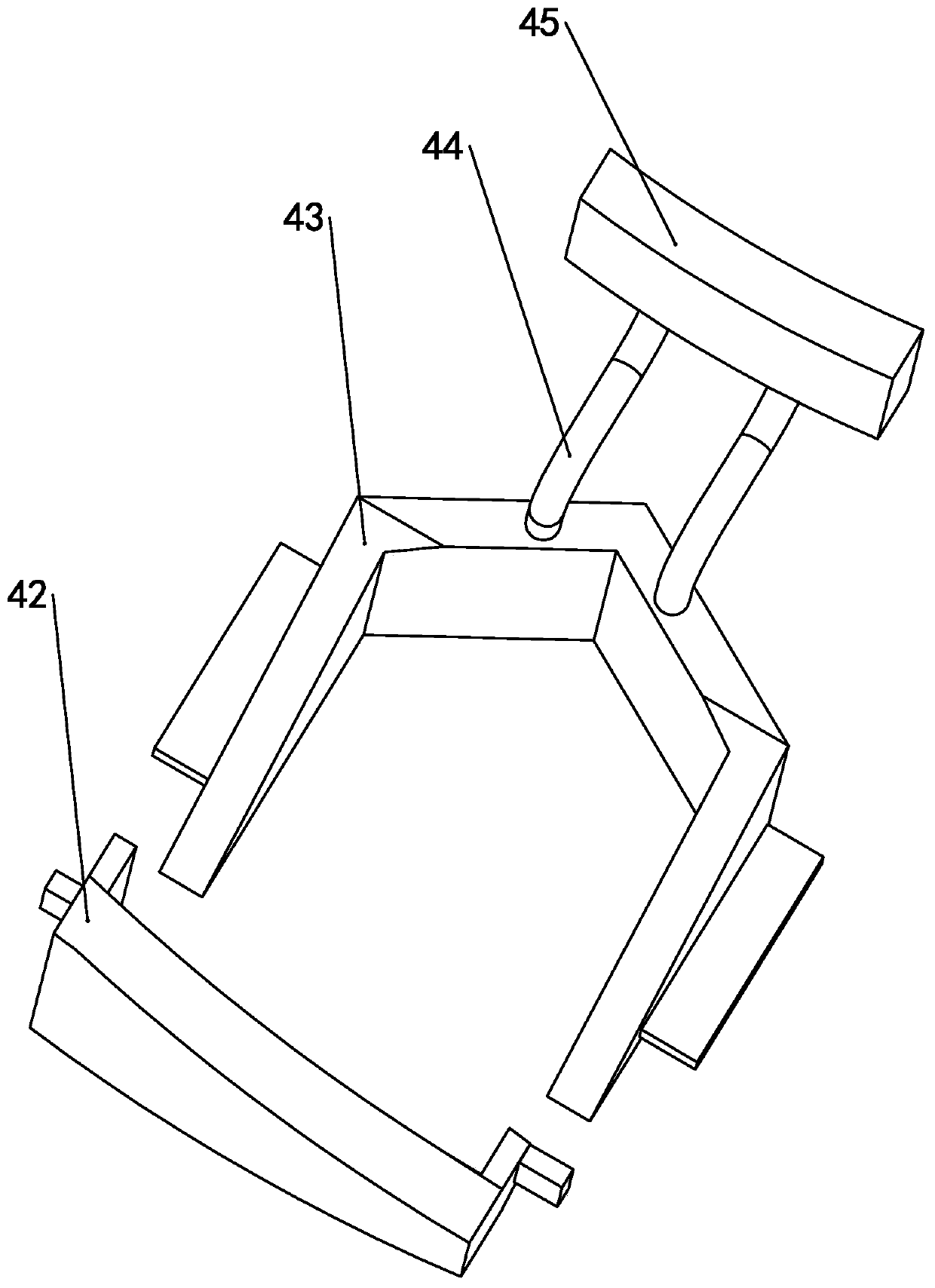

Nylon ring nesting device for nylon self-locking nut

A self-locking nut and nylon technology, which is applied to threaded products, other household appliances, household appliances, etc., can solve the problems of reduced efficiency, high positioning requirements, and high degree of cooperation between the outer diameter of the nylon ring and the stepped hole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those of ordinary skill in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention. Left, right, etc. are defined based on the top view. It should be understood that the use of the orientation words should not limit the scope of protection claimed by this application.

[0036] The center of the wooden workbench is provided with a through hole, the bottom of the wooden workbench is fixedly connected with the second stepping motor, the rotating shaft of the second stepping motor passes through the through hole, and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com