Positioning mechanism of household appliance panel riveting device

A positioning mechanism and panel technology, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve problems such as increased cost, increased number of molds, and unfavorable home appliance panel processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

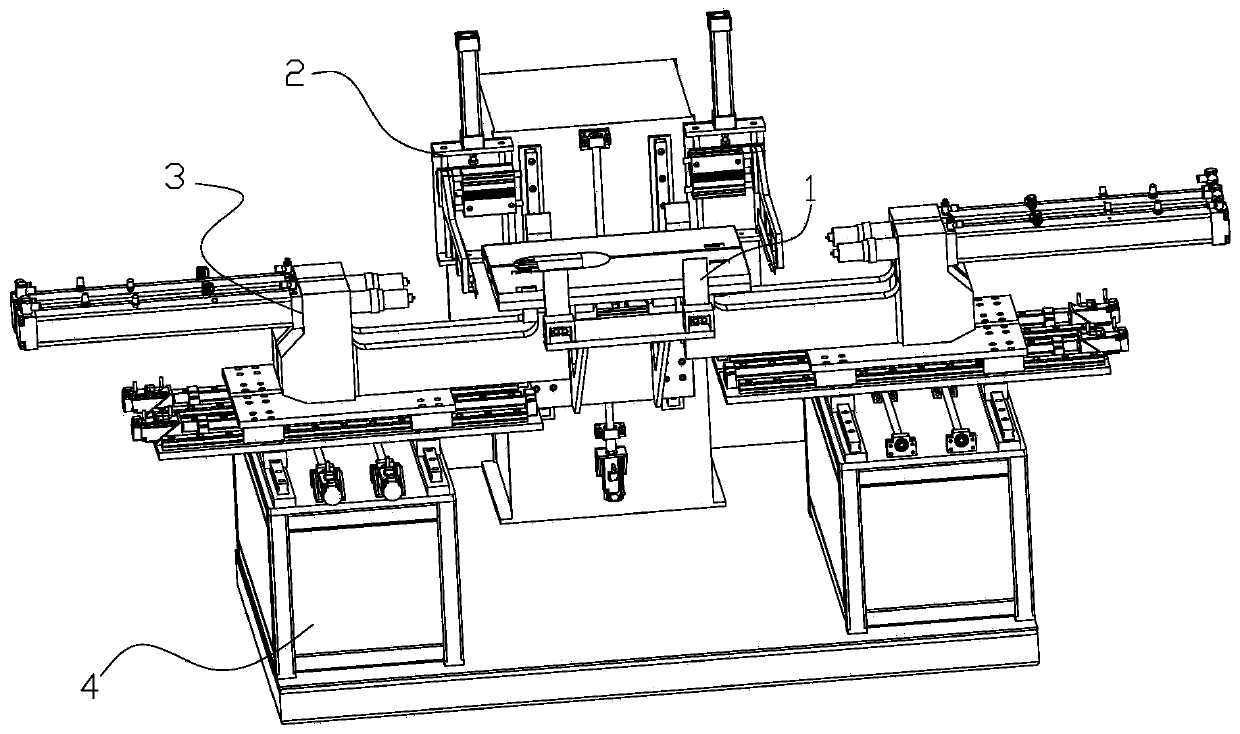

[0029] Such as figure 1 The shown riveting equipment for home appliance panels includes a bottom plate positioning mechanism 1 , a side plate positioning mechanism 2 , a riveting mechanism 3 and a frame 4 . The bottom plate positioning mechanism 1 , the side plate positioning mechanism 2 and the riveting mechanism 3 are all fixed on the frame 4 . The two riveting mechanisms 3 are fixed on the bottom surface of the frame 4 and are located on the left and right sides of the frame 4 respectively. The bottom plate positioning mechanism 1 is fixed on the front end face of the middle column of the frame 4, and the two side plate positioning mechanisms 2 are fixed on the top of the bottom plate positioning mechanism 1, and are respectively located on the left and right sides of the bottom plate positioning mechanism 1.

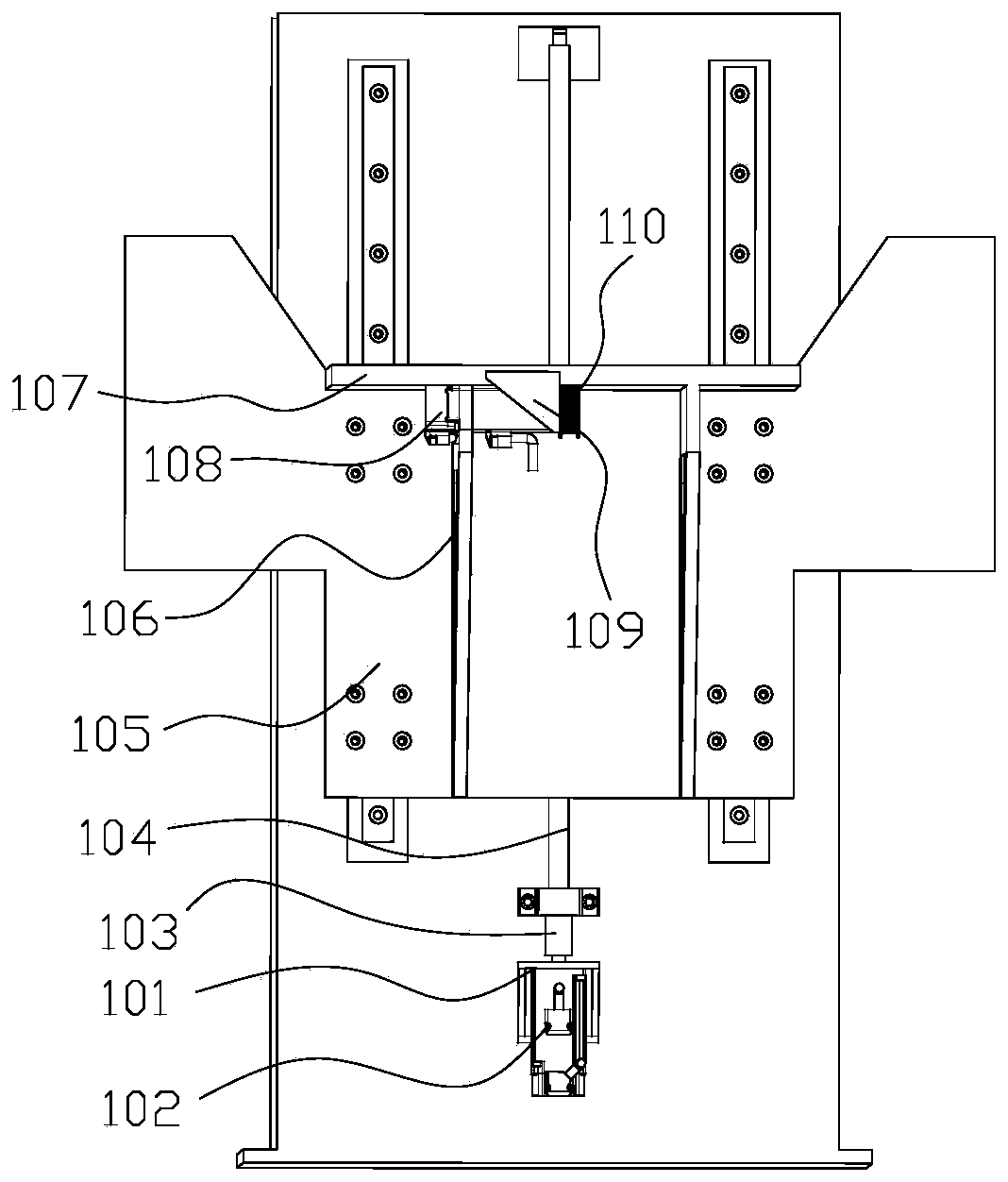

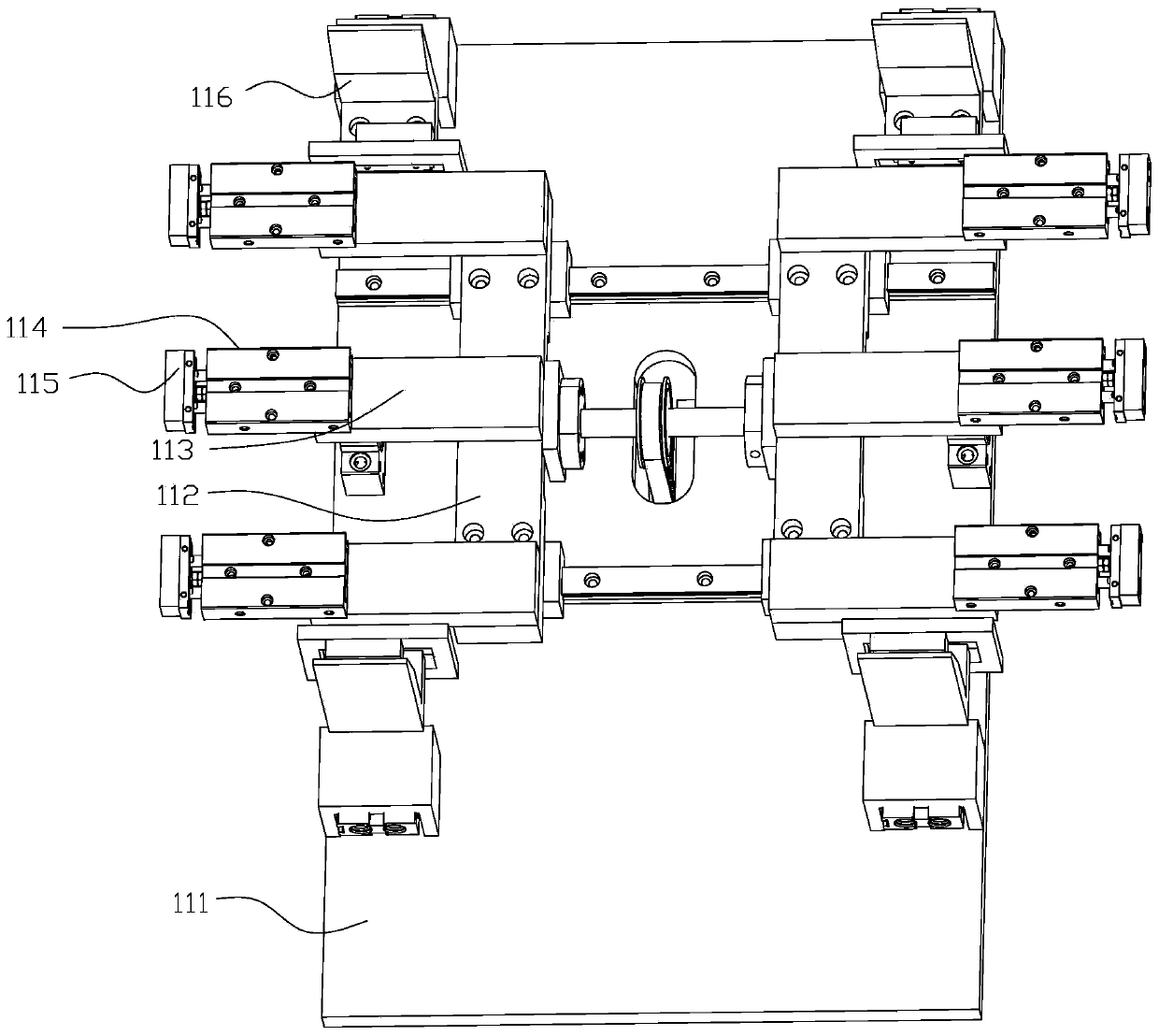

[0030] Such as figure 2 image 3As shown, the base plate positioning mechanism 1 includes a base plate first drive motor 101, a base plate first drive motor seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com