Finished cell stage screening method

A battery cell and finished product technology, which is applied in the field of finished battery cell screening, can solve the problems of production line confusion, manpower and material resources consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0014] This patent provides a variety of parallel schemes, and the different expressions belong to the improved scheme based on the basic scheme or the parallel scheme. Each scheme has its own unique characteristics.

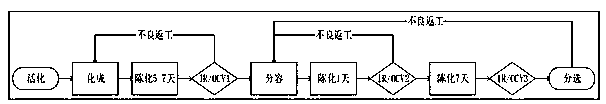

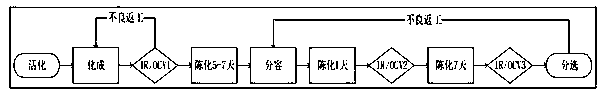

[0015] In this patent, when the screening principle is consistent, the OCV1 detection is adjusted to 5-7 days before the aging, and the defective cells are directly screened for rework. The reworked cells can be synchronized with the normal batch after aging; Modify the test range of OCV2 after capacity division and set it to the voltage range of 5-7 days of aging after formation to achieve the purpose of only testing the voltage without screening and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com