The impeller structure of a drum separator

A separator and impeller technology, applied in the direction of centrifuge, etc., can solve the problem of the decline of solid-liquid separation effect, and achieve the effect of clear liquid discharge, good separation effect and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

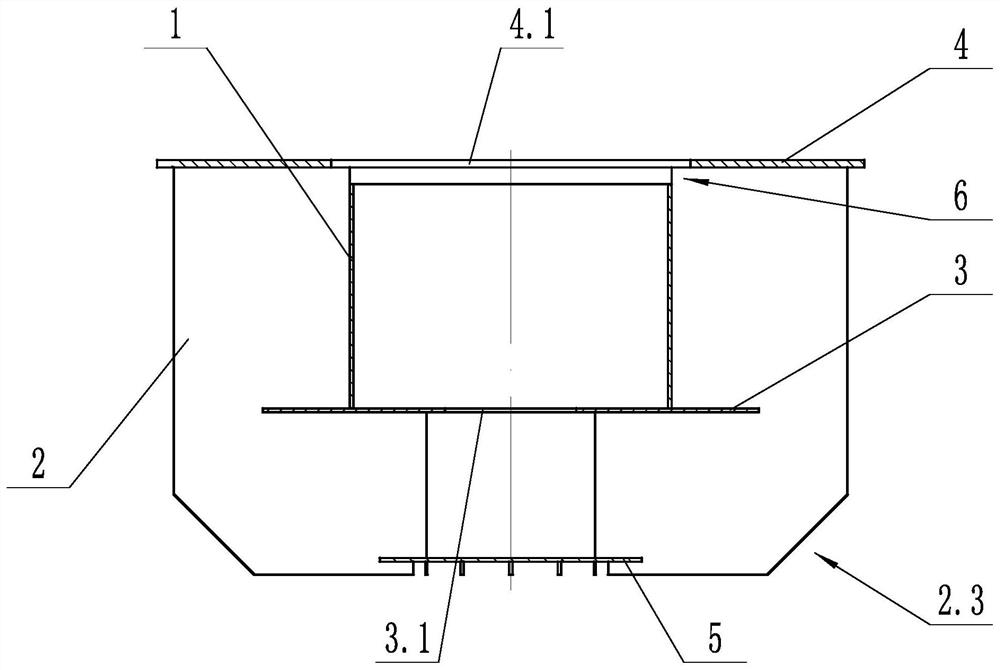

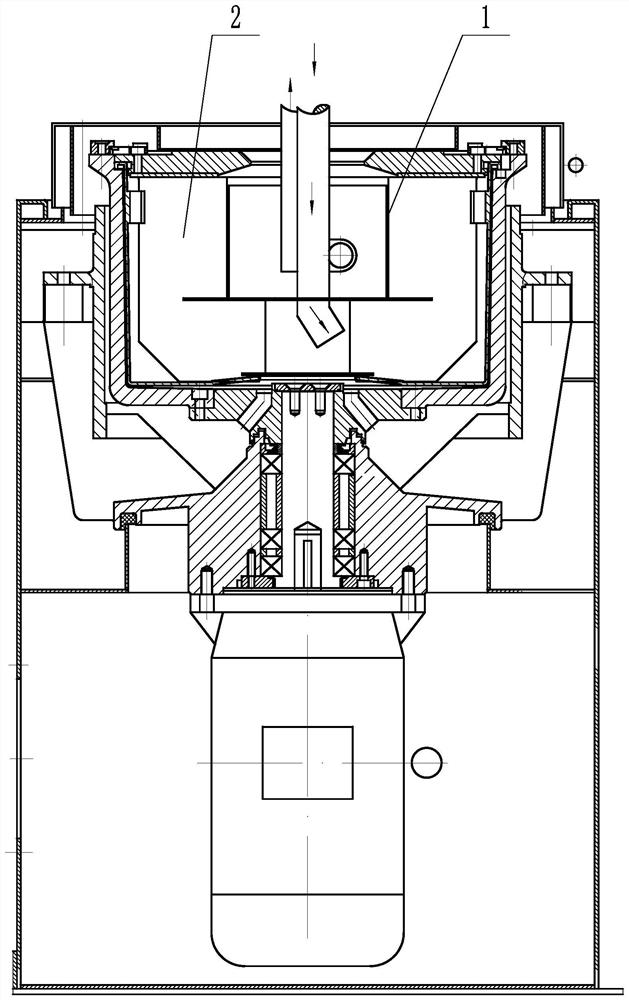

[0023] Such as figure 1 and image 3 As shown, the impeller structure of a cylindrical separator includes a cylinder 1, centrifugal blades 2 and a partition 3, the partition 3 is fixed on the bottom of the cylinder 1, and a through hole 3.1 is provided in the middle of the partition 3, and the through hole 3.1 The diameter is smaller than the inner diameter of the cylinder 1, and the outer diameter of the partition 3 is larger than the outer diameter of the cylinder 1; the centrifugal blades 2 are arranged on the outer wall of the cylinder 1, and the bottom end of the blade is arranged under the partition 3 . The outside of the bottom end of the centrifugal blade 2 is provided with a deposition notch 2.3.

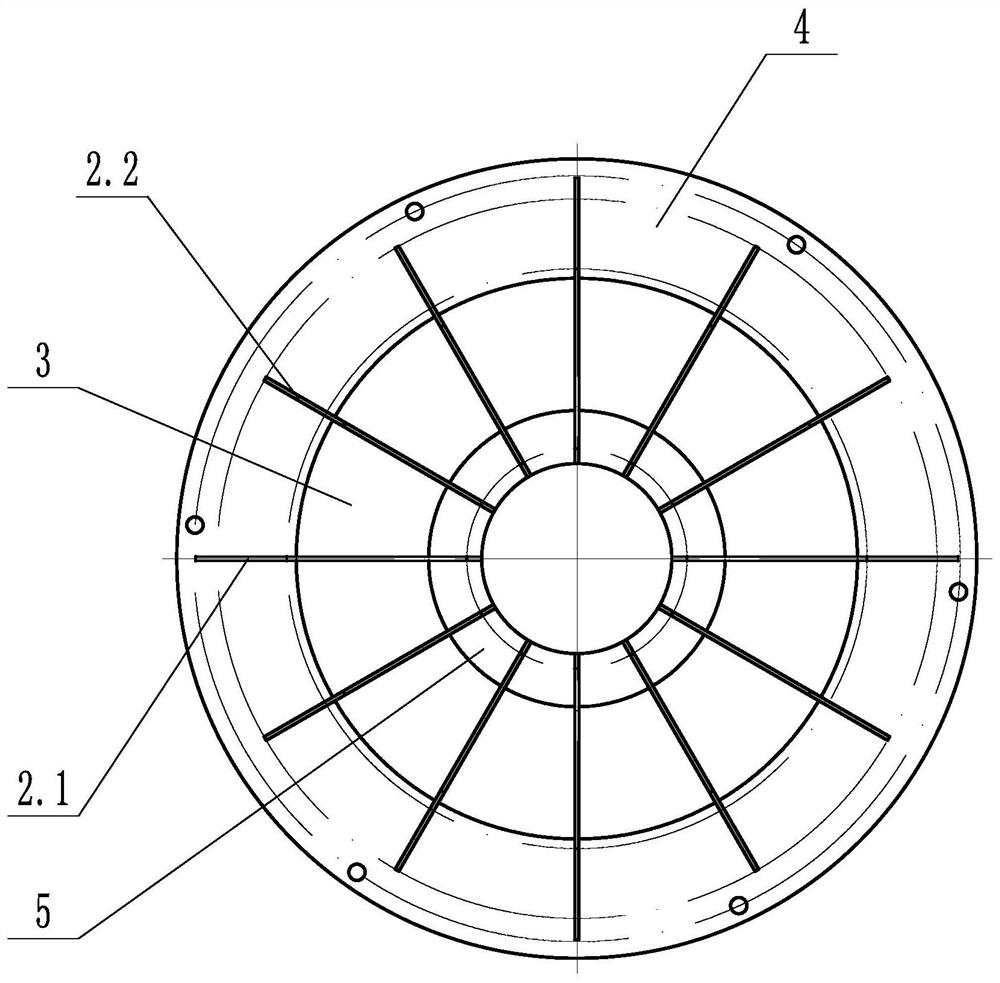

[0024] Such as figure 1 and figure 2 As shown, the centrifugal blade 2 includes a large blade 2.1 and a small blade 2.2, and the radial dimension along the large blade 2.1 is greater than the radial dimension of the small blade 2.2; the number of the large blade 2.1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com