Steering axles for motor vehicles

A technology for motor vehicles and steering shafts, which is applied to the steering control, steering column, vehicle components and other directions installed on the vehicle, and can solve problems such as damage noise and pressure difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

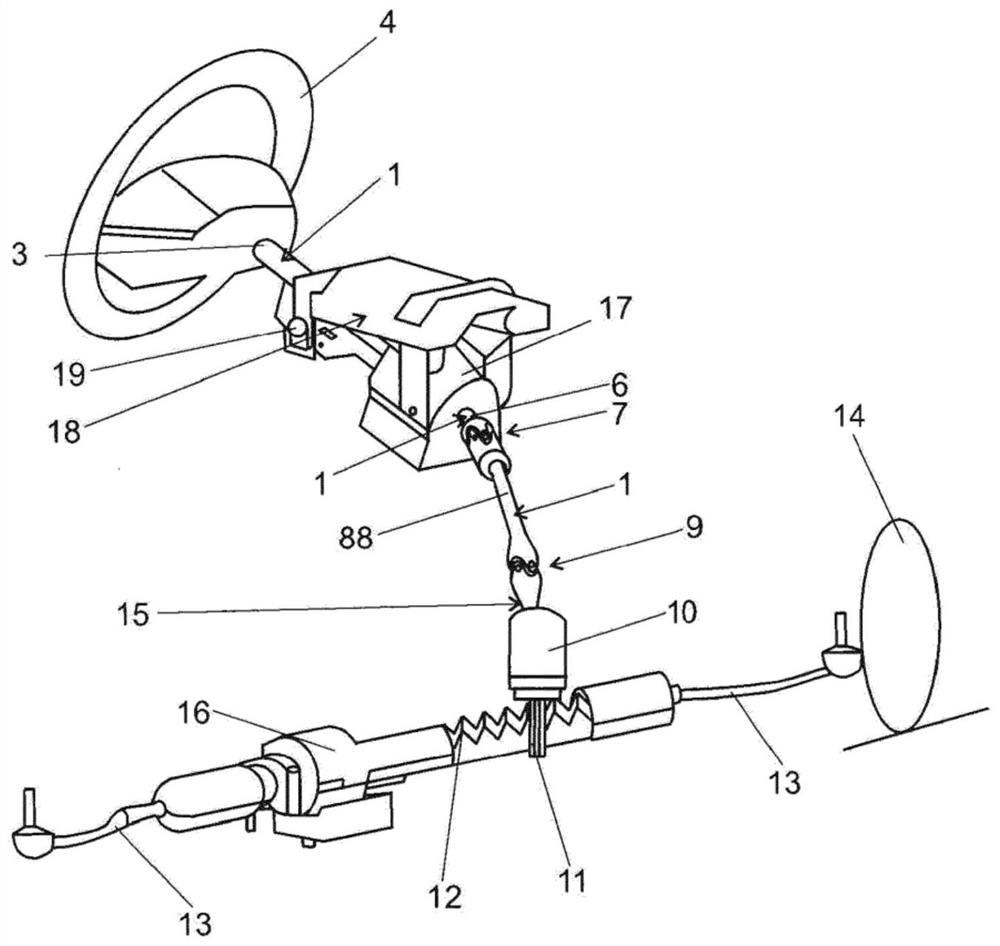

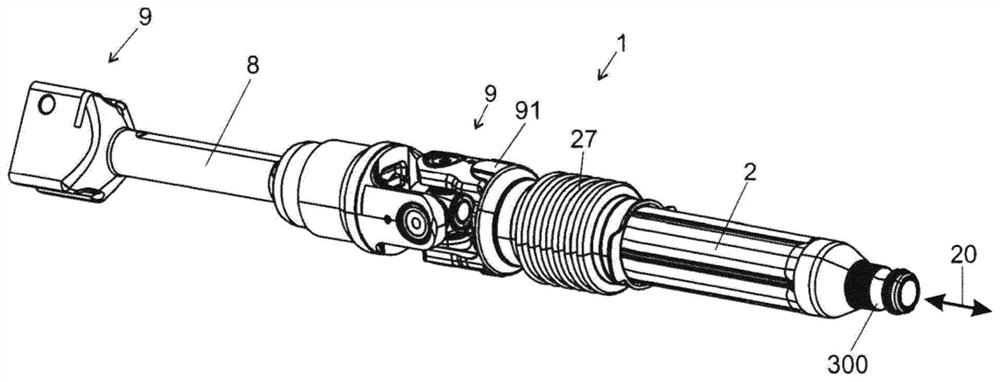

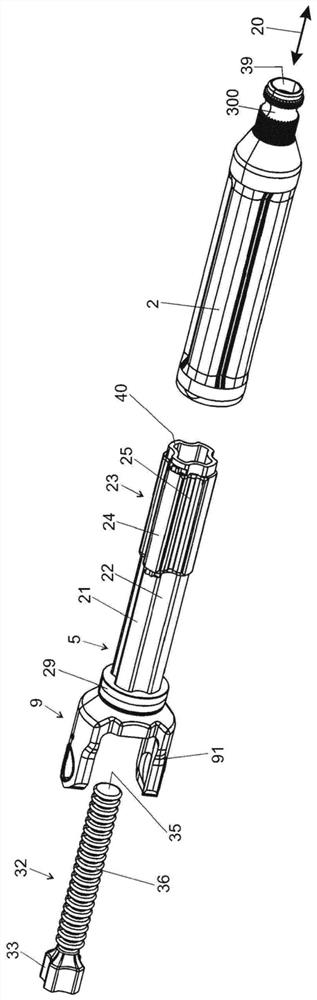

[0023] figure 1 A steering device for a motor vehicle is shown, in which case a steering shaft 1 consisting of several parts is connected to a steering wheel 4 via a steering wheel side end 3 . The steering shaft 1 has a rotary joint 7 designed as a universal joint, which is connected to a further shaft part 88 of the steering shaft 1 . The shaft part 88 is connected to the input shaft 15 of the steering gear 10 via another rotary joint 9 configured as a universal joint. The pinion 11 of the steering gear 10 interacts with the rack 12, as a result of which, in the case of rotation of the steering wheel 4, a lateral linear displacement of the rack 12 is caused, as a result of which the rotational movement of the steering shaft 1 is converted into Translational movement of the rack 12 . The rack 12 is connected at both ends via tie rods 13 to steered wheels 14 by means of which the steered wheels 14 can be pivoted. The electromechanical power steering is housed in the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com