Device for cleaning ink reservoir, printing machine, and method for cleaning ink reservoir

A technology for cleaning devices and printing machines, which is applied to the general parts of printing machinery, printing machines, printing, etc., and can solve the problem that the ink transfer roller is not divided into separate rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

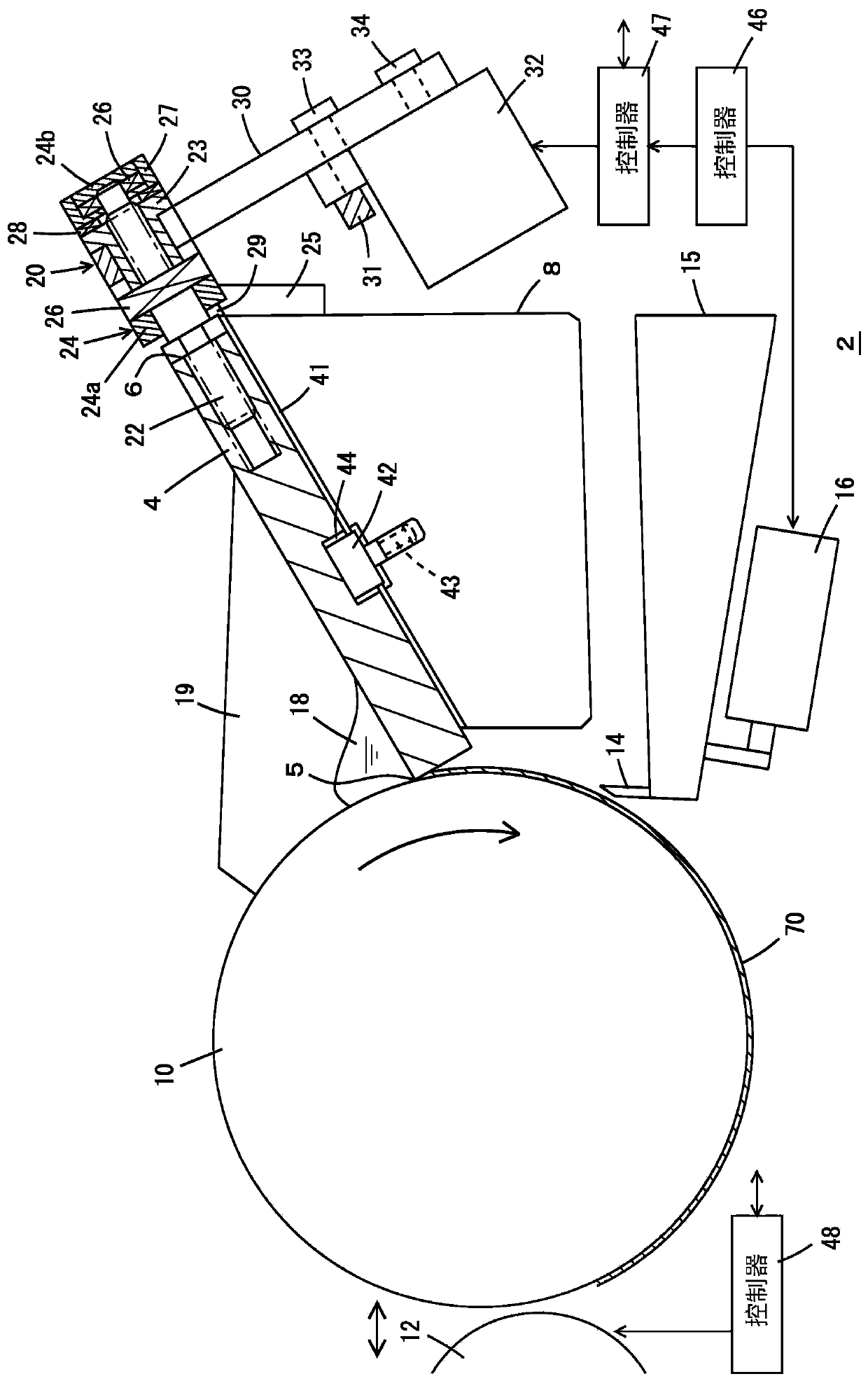

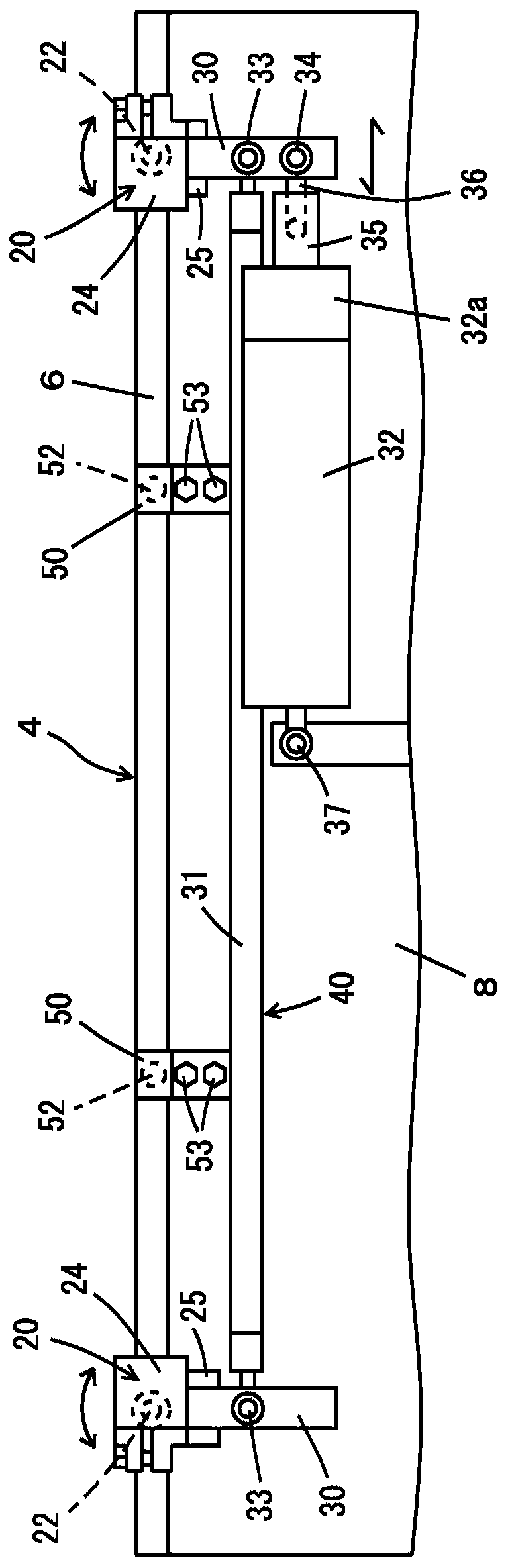

[0072] Figure 1-Figure 10 Indicates an example. figure 1 Indicates the main part of a printing machine, and the type of printing machine may be, for example, an offset printing machine or a letterpress printing machine. The printing target may be paper, or an optical disc such as a can, CD-ROM, or the like. In the case of a tank, an optical disk, etc., impurities such as water mixed in from the water tray are removed from the ink container.

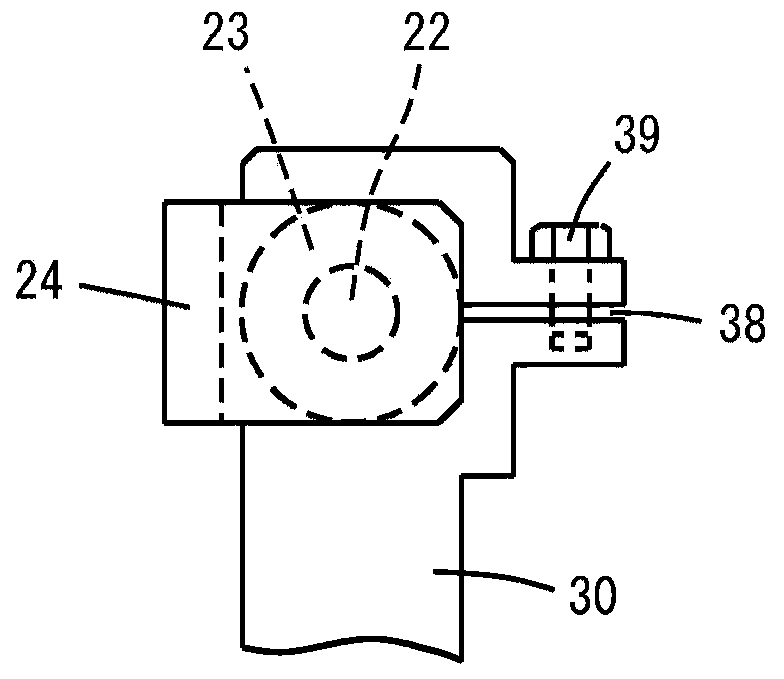

[0073] The front end 5 of the ink fountain 4 is opposite to the ink fountain roller 10, so that the gap between the front end 5 and the roller 10 can be changed into the following three types: close contact (for example, less than 10 μm) with a gap of approximately zero, normal (for example, about 0.05mm-0.2mm), Cleaning (eg about 0.2-0.3mm). A pair of left and right feed screw mechanisms 20 are provided at the base end 6 of the ink fountain 4 , and the ink fountain 4 is slid to the above-mentioned three positions by moving the stud s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com