Rock mass test flexible oil cylinder, loading system and mounting method of loading system

A loading system and oil cylinder technology, applied in the field of geotechnical engineering, can solve the problems of difficult accurate measurement of load, troublesome production, short service life, etc., and achieve the effect of large size, not easy to burst and oil leakage, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0069] Example 1. The field test uses a cylindrical rock mass sample

[0070] 1. Design shape

[0071] Such as image 3 with Figure 4 The figure shows an annular flexible oil cylinder, the inner steel frame 1b, the outer steel frame 1a and the pressure bearing oil bag 1c are all designed to be annular, and the bolt body 1e with the circular base passes through the inner steel frame 1b, the pressure bearing oil bag in sequence 1c and outer steel frame 1a, and then use gasket 1f and nut 1g to fix. The inner steel frame 1b and the pressure oil bag 1c form an oil chamber 1d, and the hydraulic oil is injected and drawn out through the hollow oil hole 1h of the bolt body 1e.

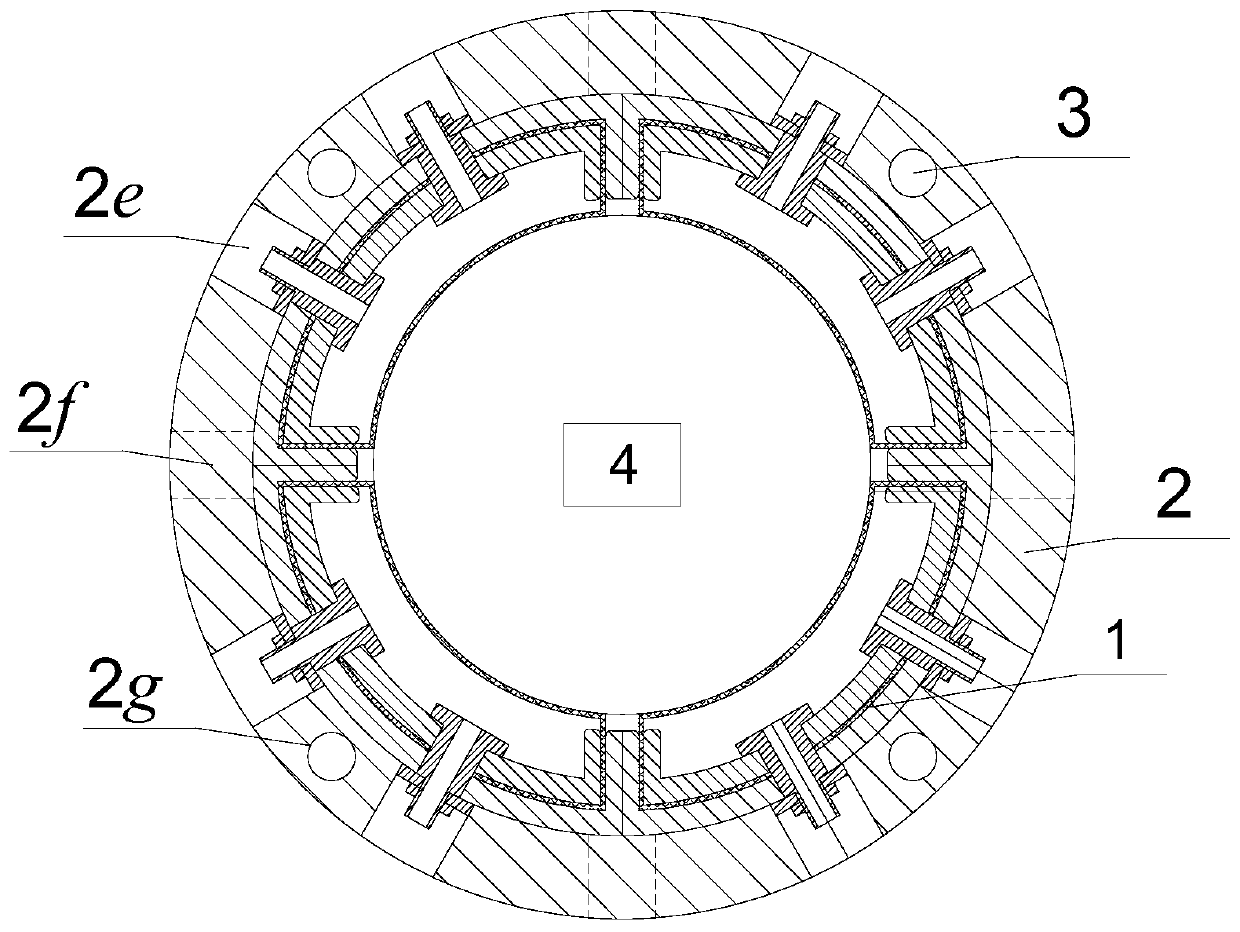

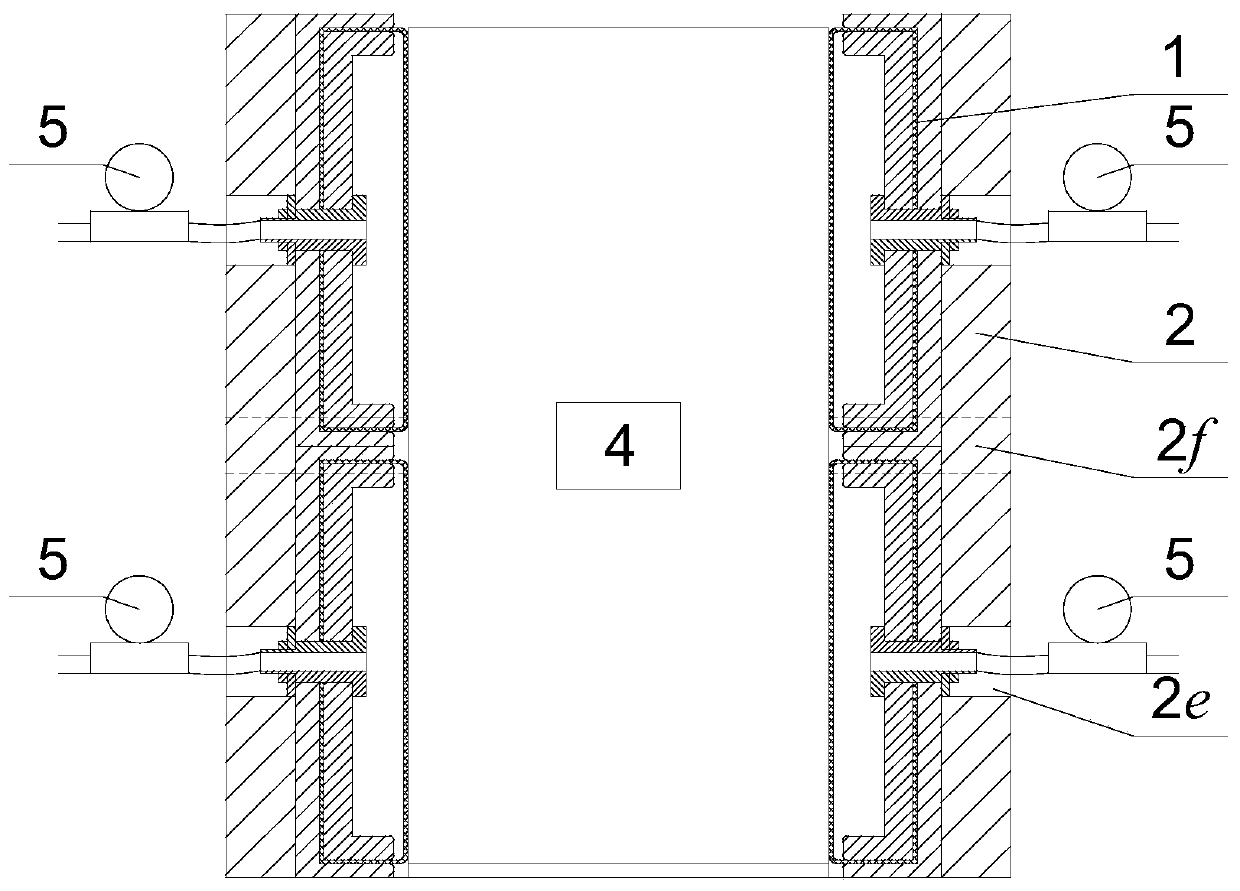

[0072] Such as Figure 5 An annular reaction force frame is provided as shown, and eight oil passage holes 2e are provided between the first frame 2a and the second frame 2b, the third frame 2c and the fourth frame 2d, and the oil passage holes 2e of the annular frame 2 and the annular The oil hole 1h of...

example 2

[0077] Example 2. The field test adopts cuboid rock mass sample

[0078] 1. Design shape

[0079] Such as Image 6 The figure shows a square flexible oil cylinder, the inner steel frame 1b, the outer steel frame 1a and the pressure oil bag 1c are all designed in a square shape, and the bolt body 1e with a circular base passes through the inner steel frame 1b, the pressure oil bag in sequence 1c and outer steel frame 1a, and then use gasket 1f and nut 1g to fix. The inner steel frame 1b and the pressure oil bag 1c form an oil chamber 1d, and the hydraulic oil is injected and drawn out through the hollow oil hole 1h of the bolt body 1e.

[0080] A square frame is provided, eight oil passage holes 2e are provided between the first frame 2a and the second frame 2b, the third frame 2c and the fourth frame 2d, the oil passage holes 2e of the square frame 2 and the oil holes of the square flexible cylinder 1h in the same position. Four symmetrical measuring holes 2f are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com