A freezer capable of realizing staged freezing and a staged freezing method

A technology of freezer and freezing pipe, which is applied in the direction of earth drilling, mining equipment, shaft equipment, etc., which can solve the problems of early excavation, unfavorable lower excavation, and difficulty in adjustment, so as to reduce the total cost of freezing and reduce hole making The effect of reducing the amount of construction and reducing the amount of hole-making work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

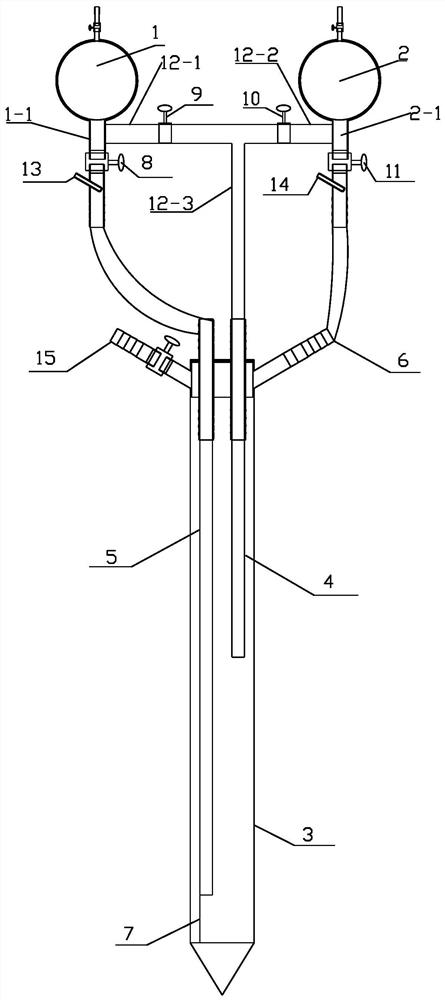

[0031] Embodiment 1 can realize the freezer of staging freezing

[0032] The freezer capable of freezing in stages in this embodiment includes a liquid distribution ring 1, a liquid collection ring 2, a tee, a freezing pipe 3, an upper frozen liquid supply pipe, a lower frozen liquid return pipe 4, and a lower frozen liquid supply pipe 5,

[0033]The bottom end of the upper frozen liquid supply pipe and the lower frozen liquid return pipe 4 and the lower frozen liquid supply pipe 5 extend into the inside of the frozen pipe 3 along the axis of the frozen pipe 3, and the upper frozen liquid supply and The upper ends of the lower frozen liquid return pipe 4 and the lower frozen liquid supply pipe 5 extend out from the top of the frozen pipe 3; the distance between the bottom of the lower frozen liquid supply pipe 5 and the bottom of the frozen pipe 3 is smaller than that of the upper section The distance between the frozen supply liquid and the bottom of the frozen liquid return ...

Embodiment 2

[0054] The freezer capable of realizing staged freezing described in Embodiment 1 is used to freeze the formation in stages.

[0055] The specific freezing method is as follows:

[0056] 1. When the upper section is frozen, open the three-way first valve 9 and the second valve 11, close the first valve 8 and the three-way second valve 10, so that the low-temperature brine passes through the three-way first end 12- 1. The third end 12-3 of the tee flows into the upper frozen liquid supply and the lower frozen liquid return pipe 4, enters the staged freezing interface, then rises along the annular space of the frozen pipe 3, and then passes through the upper frozen liquid return pipe 6, The liquid collection pipe 2-1 flows back to the liquid collection ring 2 to realize the freezing of the upper section.

[0057] 2. When freezing in the lower stage, open the first valve 8 and the second valve 10 of the three-way, close the first valve 9 and the second valve 11 of the three-way,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com